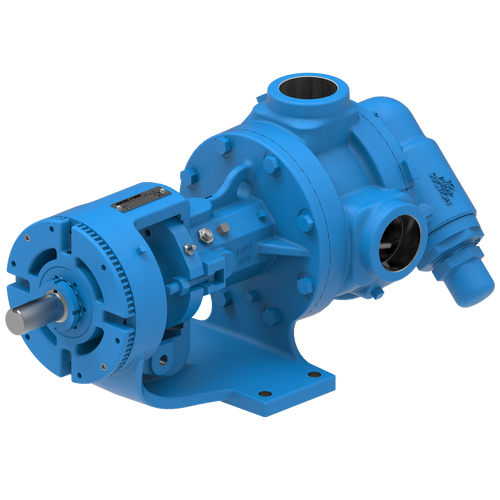

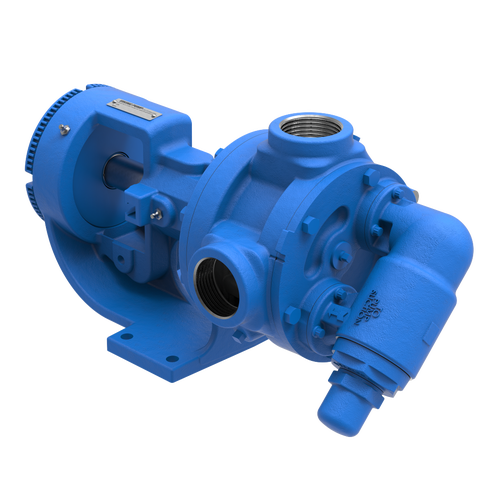

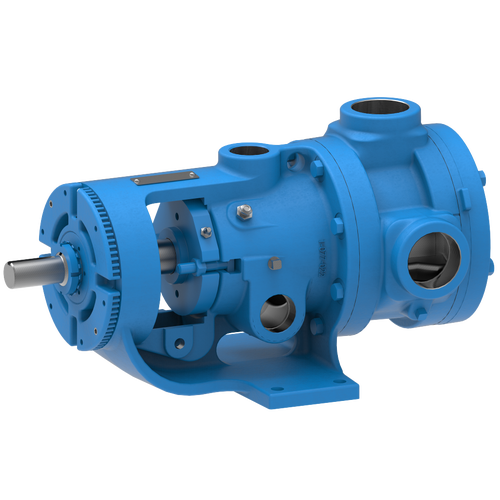

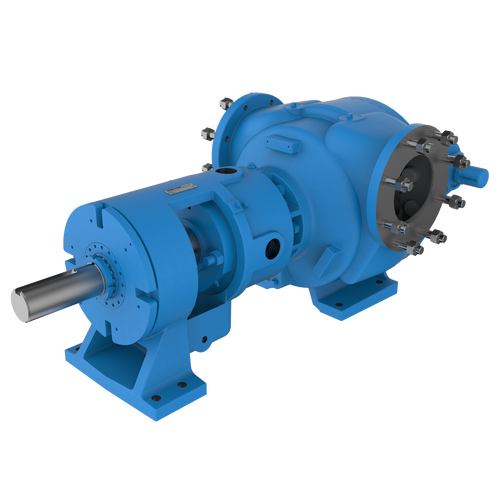

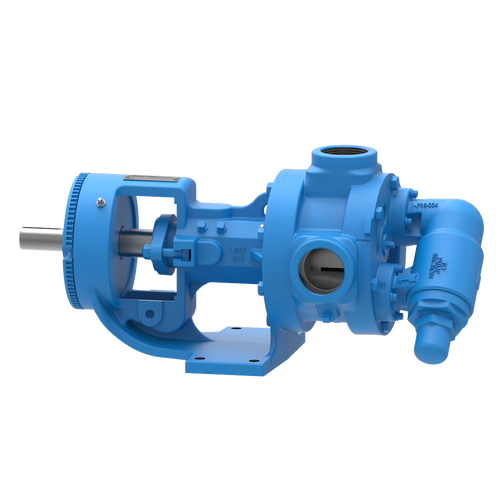

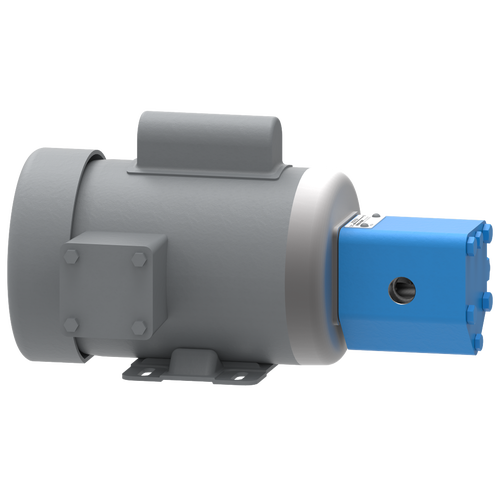

The 1124C Series™ internal gear pump is a cornerstone of Viking Pump's Universal Product Line, delivering exceptional reliability and versatility for a wide range of fluid handling applications. Featuring the innovative U-Plus™ bracket design, these pumps come standard with Viking's patented O-Pro® seal technology but have the ability to adapt to your ideal sealing needs.

Designed for adaptability, the 1124C Series™ offers multiple configuration choices and is fully compatible with ProPort™ casings, providing flexible flange types, sizes, and port arrangements for seamless system integration. Ideal for applications such as lubrication systems, hydraulic oil circulation, chemical processing, fuel transfer, and more, the 1124C Series™ ensures dependable performance across diverse operating conditions.

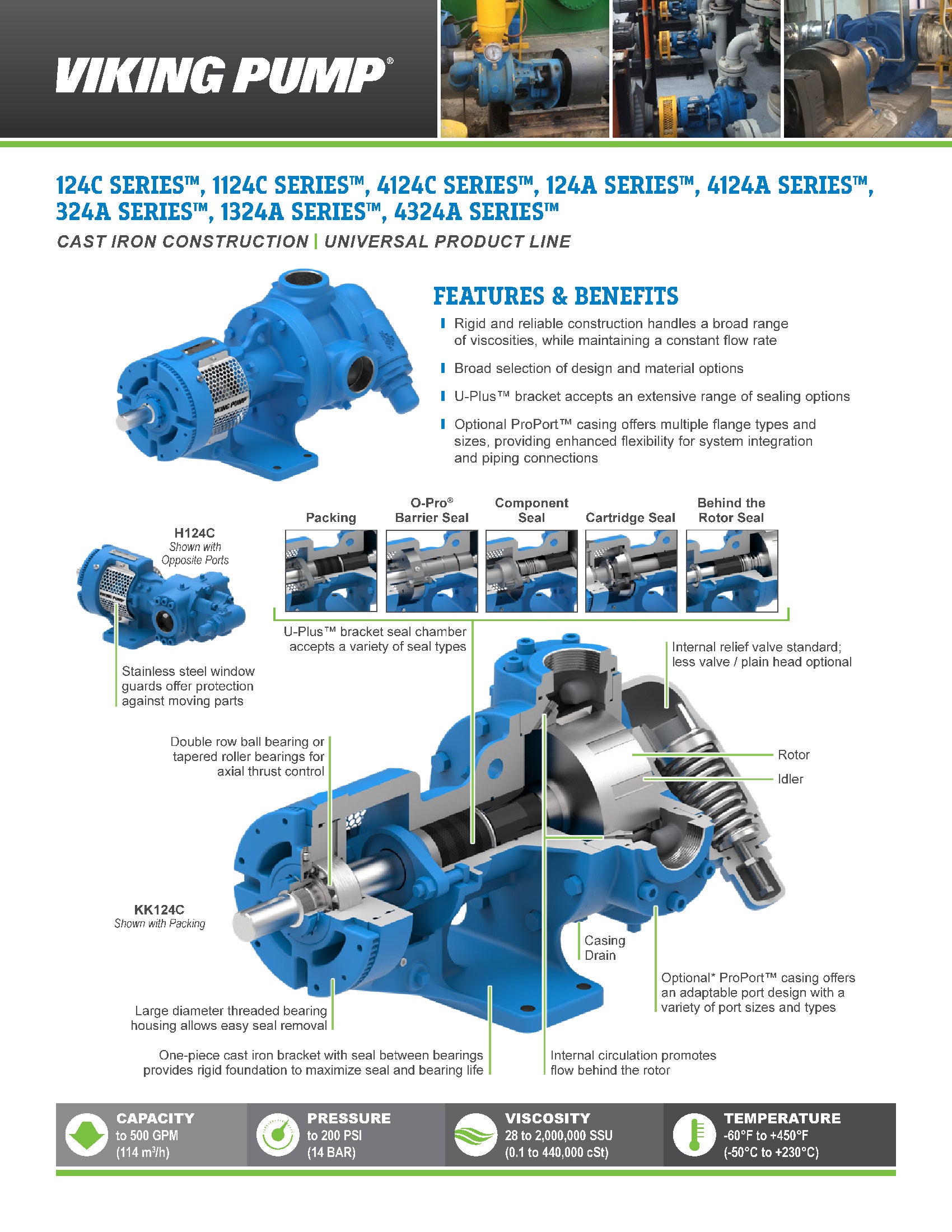

Features & Benefits

- Positive displacement internal gear pumping principle handles a wide range of viscosities with constant flow rate

- U-Plus™ Bracket adapts the pump's sealing solution to fit your needs.

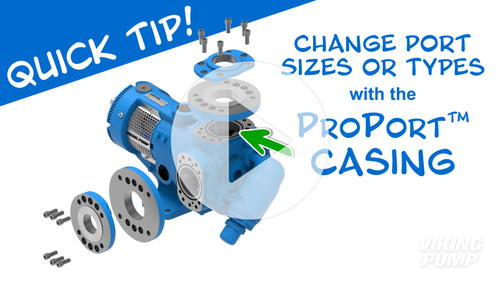

- Optional ProPort™ Casing offers a variety of port sizes and types, simplifying integration into your existing piping systems

- Stainless steel window guards offer protection from rotation parts

Capacity

8 to 400 GPM

1.8 to 91 m³/h

Viscosity

100 to 75,000 SSU

20 to 17,000 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

0 to +350 °F

-15 to +175 °C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating GPM | Nominal Pump Rating m3/h | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H1124C | 1.5 inches | 8 GPM | 1.8 m3/h | 1000 RPM | 200 PSI | 14 BAR |

| HL1124C | 1.5 inches | 18 GPM | 4 m3/h | 1000 RPM | 200 PSI | 14 BAR |

| K1124C | 2 inches | 80 GPM | 18 m3/h | 780 RPM | 200 PSI | 14 BAR |

| KK1124C | 2 inches | 100 GPM | 23 m3/h | 780 RPM | 200 PSI | 14 BAR |

| L1124C | 2 inches | 135 GPM | 31 m3/h | 640 RPM | 200 PSI | 14 BAR |

| LL1124C | 3 inches | 140 GPM | 32 m3/h | 520 RPM | 200 PSI | 14 BAR |

| LS1124C | 3 inches | 200 GPM | 45 m3/h | 640 RPM | 200 PSI | 14 BAR |

| Q1124C | 4 inches | 275 GPM | 62 m3/h | 470 RPM | 200 PSI | 14 BAR |

| QS1124C | 6 inches | 400 GPM | 91 m3/h | 470 RPM | 200 PSI | 14 BAR |

Videos

Adhesives

Adhesives are a group of substances, such as cement, glue, mucilage, and paste that are capable of holding materials together by surface attachment. Adhesives are made from many different basic materials, among them dextrin, latex, silicones, liquid rubber, resin, sodium silicate, and starch.

Black Liquor Soap

A natural intermediate byproduct of kraft pulping, black liquor soap is the rosin and fatty acid content that floats to the top as black liquor is left to settle. It is skimmed off and can be used as a raw material for tall oil production. Black liquor soap can be somewhat abrasive and range in viscosity from 22 to 5500 cP, depending on the temperature it is handled at.

Caulks

Caulks can be silicone, acrylic, or latex based adhesives and sealants used in industrial and home construction. Typically high viscosity & shear sensitive.

Greases

Commonly referred to as lubricating, automotive, or bearing grease. Generally mixtures of a mineral oil with one or more metallic soaps; the most common are those of sodium, calcium, barium, aluminum, lead, lithium, potassium and zinc. The texture of grease may be smooth, buttery, ropy, fibrous, spongy or rubbery and have a variety of viscosities.

Isocyanate

Also known as TDI, MDI, or diisocyanate. Isocyanate is used as a hardening or curing agent in polyurethane foams, industrial coatings, elastomers, inks, and resins. It is extremely sensitive to moisture in the air and hydrocarbons making air-tight seal options extremely critical.

-

DRAWINGS

H-HL with Plain Head - 1.5" NPT RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with RV and ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

K-KK with Plain Head - 2" NPT RH/LH PDF

STEP

K-KK with Plain Head - 4" Class 125 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" NPT RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

K-KK with Relief Valve - 2" NPT RH/LH PDF

STEP

K-KK with Relief Valve - 4" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with Plain Head - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 2" NPT RH/LH PDF

STEP

L with RV and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

Q with Plain Head - 4" Class 125 ANSI RH/LH PDF

Q with ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q with Relief Valve - 4" Class 125 ANSI RH/LH PDF

STEP

Q with RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q-QS with RV and ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with Plain Head - 6" Class 125 ANSI Opposite PDF

STEP

QS with ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with ProPort Casing - 6" Class 250 ANSI Opposite PDF

QS with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

QS with RV and ProPort Casing - 6" Class 250 ANSI Opposite PDF