Greases

Greases

Custom Content One

Positive displacement gear pumps are ideal for transferring greases in manufacturing because they handle high-viscosity fluids effectively. These pumps trap a set amount of grease, forcing it through the discharge pipe to ensure a steady flow, even with system pressure changes. This makes them especially good for thick greases that resist flow in situations where other pumps might fail. Gear pumps have simple mechanisms that reduce shear and turbulence, maintaining the grease's performance qualities. Their sturdy design and reliability mean less maintenance and downtime, supporting continuous manufacturing operations. Overall, the precision, reliability, and adaptability of these pumps make them perfect for industries needing efficient transfer of dense materials like greases.

Recommended Pumps

-

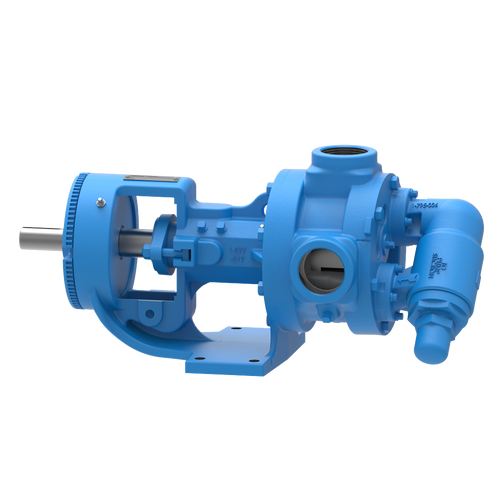

1124A Series™

- Cast Iron

- O-Pro® Seal

- 15-500 gpm | 1.8-91 m3h

-

1127C Series™

- Stainless Steel

- O-Pro® Seal

- up to 320 gpm | up to 73 m3h

-

124A SERIES™

- Cast Iron

- Packing

- up to 500 gpm | up to 114 m3h

Articles / Case Studies

Grease is an essential component in various industries, ensuring that machinery and equipment operate smoothly. A grease transfer pump plays a crucial role in the efficient handling of grease, whether for automotive, industrial, or other applications. Here we will explore the characteristics of grease, the challenges associated with pumping it, and the grease transfer pump solutions offered by Viking Pump.

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025