From a Hole in the Ground to a New Venture

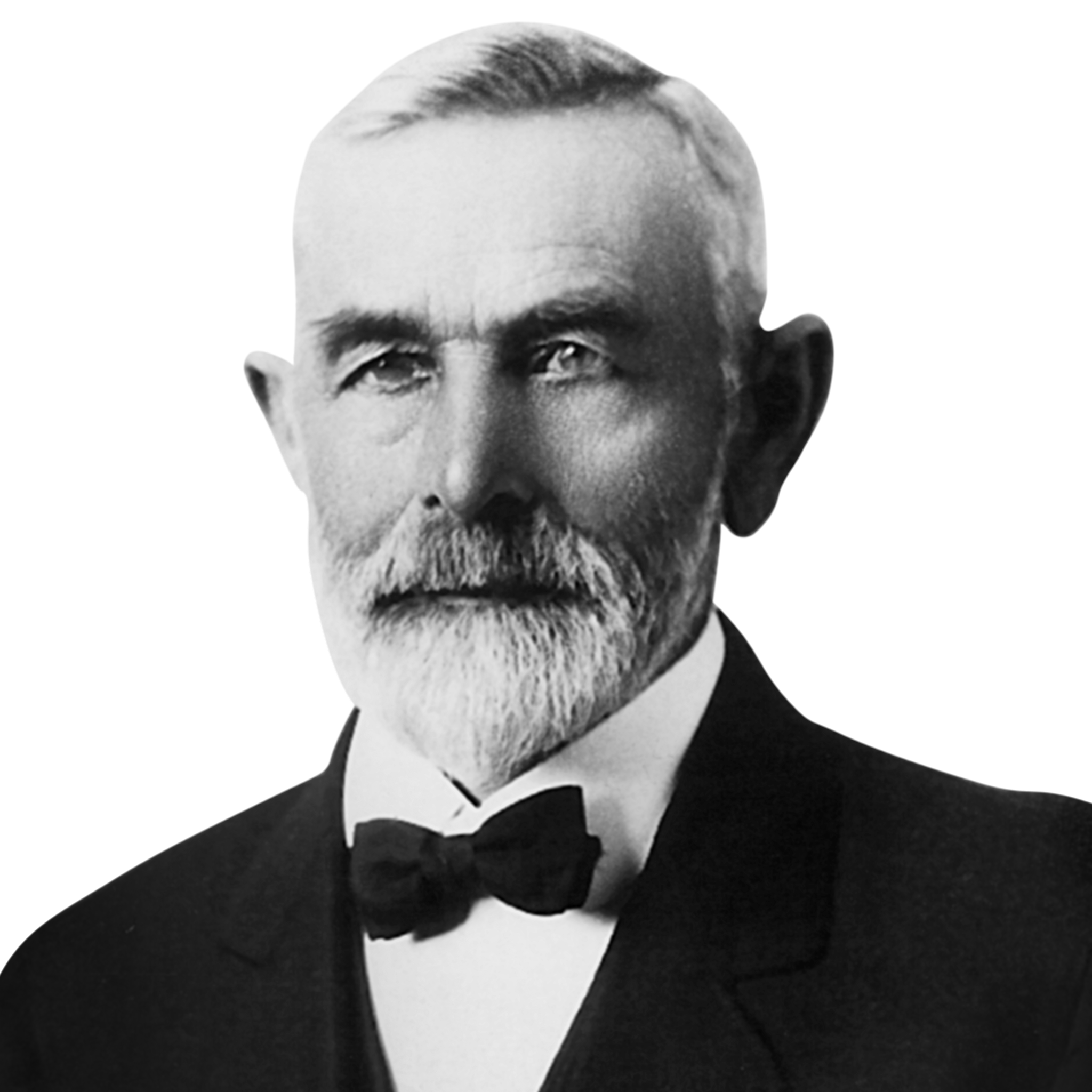

Jens Nielsen had a problem. He operated a limestone quarry in Cedar Falls, Iowa – a quarry that kept flooding. External gear pumps of the day could not lift the water high enough to pump the water to a nearby creek – so Nielsen got to work on a new pump design.

By 1904, Nielsen had a working prototype: a rotary internal gear pump capable of lifting the water out of the quarry. In 1911, he partnered with three other Cedar Falls residents - P.C. Petersen, Dr. W.L. Hearst, and George Wyth to form Viking Pump Company. With three of the four founders being of Danish descent, they named it after the explorers they admired. That first year, two employees built fifty pumps and generated $2,000 in sales.

Building from the Ground Up

In 1912, Viking Pump moved into a 2,400 square foot factory on State Street in downtown Cedar Falls. That building still stands today – a small part of a 154,000 square foot headquarters. The company expanded into the Cedar Falls Industrial Park in 1960 and built its own iron foundry in 1976. This vertical integration—casting, machining, assembling, and testing all in-house—became a defining advantage.

Going Global

Viking Pump was acquired by Houdaille Corporation in 1968, then became part of IDEX Corporation in 1989. Under IDEX, the company accelerated international expansion: a manufacturing facility in Shannon, Ireland; Viking Pump Hygienic Ltd. in Eastbourne, UK for food and pharmaceutical applications; and Viking Pump Canada in Windsor, Ontario. Today, Viking Pump ships to over 200 countries on all seven continents through a network of factory-trained distributors.

An Expanded Product Portfolio

Nielsen's original internal gear design evolved over the decades to include many models of internal gear pumps and grew to include other technologies. The expanded portfolio allows the business to provide pumping solutions to almost every industry. Viking Pump's products now span four segments, each engineered for specific industry demands.

The Industrial Segment offers pumps for general manufacturing applications: refined fuels and lubricants, resins and polymers, paints and inks, asphalt and bitumen, heat transfer fluids, and more. The segment includes the flagship Universal product line which offers flow rates up to 1,600 GPM across dozens of models, while Motor Speed pumps deliver a compact footprint for thin to moderate viscosity applications without requiring gear reducers.

Energy Segment products serve the oil and gas industry, specifically upstream and midstream applications. The GB-425, GB-414, and 410 Series™ external gear pumps handle applications from LACT (Lease Automatic Custody Transfer) pipeline injection to natural gas dehydration (glycol) at pressures up to 1,500 PSI. These pumps are engineered for field rebuildability—hardened parts, back pull-out seal designs, and simple rebuild kits.

Hygienic Segment pumps serve food and beverage, personal care, pharmaceutical and biopharmaceutical industries where cleanliness and gentle product handling are critical. This segment houses rotary lobe and circumferential piston pumps with clean-in-place (CIP) and sterilize-in-place (SIP) capabilities. The SteriLobe® Series handles proteins and cells in pharmaceutical and biopharmaceutical manufacturing; while the Classic+ Series™ serves food production from bakeries to breweries.

The new Transport Segment pumps are designed specifically for tanker trucks. The fully stainless-steel RTP® Series rotary lobe pump serves hygienic road tankers hauling food and beverage items like high fructose corn syrup, chocolate, and dairy—reducing loading and unloading time by over 30%. The RTPe® Series handles chemical tankers carrying caustics, corrosives, and fertilizers utilizing its stainless steel wet end construction. The new RTPg Series™ brings internal gear technology to petroleum and cooking oil applications in a cost-effective cast iron design.

Recent Developments

Viking Pump continues to evolve its core product line. The U-Plus™ bracket and ProPort™ casing represent a major redesign of the company's flagship internal gear pumps. The U-Plus™ bracket accepts multiple seal types—cartridge, component mechanical, packing, or O-Pro® seals—in a single pump, allowing operators to switch sealing methods without replacing equipment. The ProPort™ casing uses bolt-on ports rather than a single piece casing - giving customers and distributors flexibility to customize port sizes and types on demand.

In the transport segment, the RTPg Series™ brings Viking Pump’s internal gear technology to tanker truck applications in a cost-effective cast iron design. The fully rebuildable pump eliminates "throw away" units and handles flows up to 170 GPM. Manufactured and assembled in the USA, it's designed for operators who need reliability without the cost of stainless steel.

Still Here, But Everything has Changed

115 years after Nielsen built that first pump to drain his quarry, Viking Pump remains headquartered in Cedar Falls. What started as a single design for solving an individual problem has evolved into multiple product lines, dozens of industries served, and a global manufacturing footprint. The original "gear within a gear" principle still works today— and it shows that there’s always room for an evolution of excellence.

For over a century, Viking Pump has been the global leader in positive displacement pumping solutions, trusted by industries worldwide for their expertise, innovation, and reliability. With deep knowledge across a wide range of applications—from chemicals and coatings to food and fuel—Viking Pump delivers engineered solutions that keep processes flowing smoothly.