Caulks

Caulks

Custom Content One

Positive displacement pumps are ideal for manufacturing caulks because they provide consistent and precise flow rates, which are crucial for ensuring the uniformity and quality of the final product. These pumps can handle high-viscosity materials like caulk without losing efficiency, making them well-suited for the thick, paste-like consistency of caulk. Additionally, positive displacement pumps offer excellent control over the pumping process, allowing manufacturers to maintain accurate proportions of ingredients in the formulation of caulks. Their ability to handle a wide range of pressures and flow rates ensures that the manufacturing process remains stable and efficient, reducing waste and improving product quality.

Recommended Pumps

-

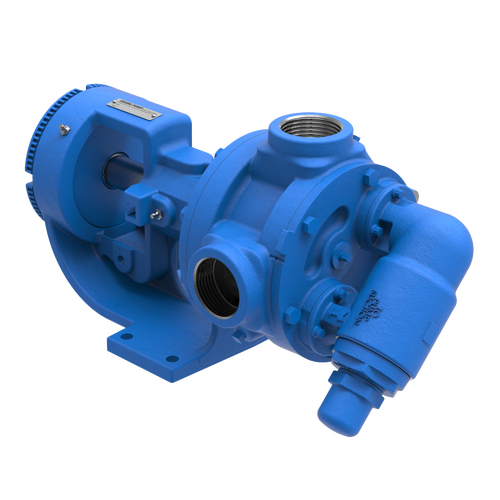

1124A Series™

- Cast Iron

- O-Pro® Seal

- 15-500 gpm | 1.8-91 m3h

-

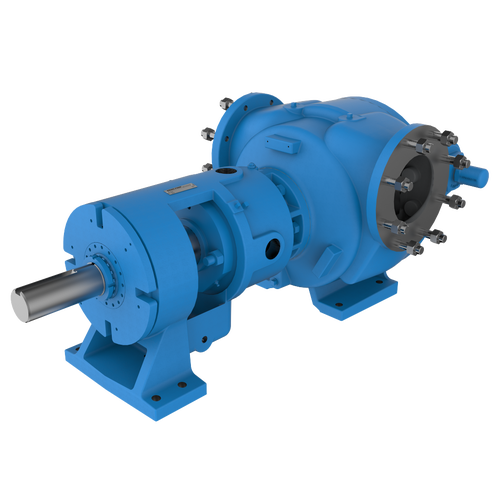

1324A SERIES™

- Cast Iron

- O-Pro® Seal

- 500-1300 gpm | 136-295 m3h

-

4124B Series™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

Articles / Case Studies

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Unlike most of my colleagues I didn’t start out with a mechanical background. While they were studying kinetics and machine design, I was studying digital electronics and industrial power. When I started my career in the world of pumps, I had to learn a whole new set of concepts. What was surprising was that while the terminology may be a bit different, the concepts are very similar. Think of the following as a “Rosetta Stone” for translating the common terms and concepts of fluid systems to your more familiar terms and concepts of electrical systems.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025