Adhesives

Adhesives

Custom Content One

Positive displacement pumps are ideally suited for transferring adhesives due to their ability to handle viscous, shear-sensitive, and sometimes abrasive materials with precision and care. Unlike centrifugal pumps, positive displacement pumps displace a specific volume of fluid with each cycle, ensuring a consistent flow rate that is crucial for maintaining the quality and integrity of adhesives during transfer. This is especially important when dealing with adhesives that require an even application to function correctly. Furthermore, these pumps offer superior control over pressure and flow, minimizing the risk of damaging the adhesive structure or altering its properties through excessive shear. Their versatility in handling a wide range of viscosities and their capability to pump fluids with uniform delivery make positive displacement pumps an excellent choice for adhesive applications.

Custom Content One

Viking in the Process

Adhesives is a broad category covering many materials, presenting unique challenges for which Viking Pump has proven solutions. They may range in viscosity from water thin solvents to extremely viscous polymers. Some are shear sensitive and require larger pumps operating at slow speeds, and some require double seals with barrier fluid or magnetic drives to prevent air or humidity contact at seal faces which can cause sticking or crystallization. Viking’s O-Pro® seal provides a lower-cost solution with grease barrier between dual dynamic O-rings to prevent air infiltration at the seal.

Custom Content Two

Applications

- Manufacturing and packaging adhesives (e.g. PVAc, polyurethanes, epoxy resins)

- Transfer from onsite blending (e.g. starch kitchen) to application and return

- Metering onto items to be bonded

Recommended Pumps

-

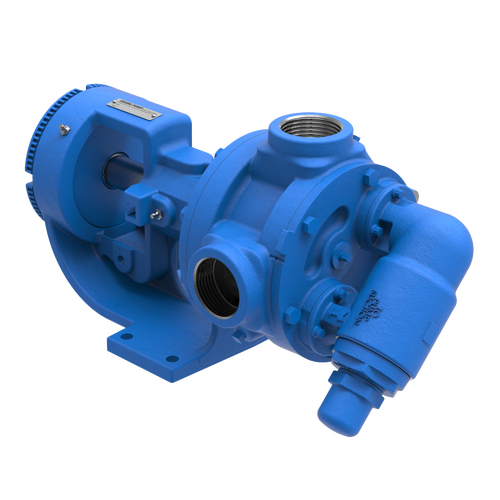

1124A Series™

- Cast Iron

- O-Pro® Seal

- 15-500 gpm | 1.8-91 m3h

-

4124B Series™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

8124A SERIES™

- Cast Iron

- Mag Drive

- up to 500 gpm | up to 114 m3h

Articles / Case Studies

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their dynamically-sealed cousins with...

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025