Margarine

Margarine

Custom Content One

Margarine is a butter substitute derived from vegetable oils. It is often seen as a healthier option to butter as it contains fewer unsaturated fats.

Margarine (or oleomargarine) can be used as a spread or as an ingredient in other foods like baked goods. It is an oil/water emulsion which by US law must contain 80% fat. Products with less than 80% fat are called “spreads.” Commonly used vegetable oils include soybean oil, sunflower oil, canola oil, and palm oil, although some margarines may include animal fats. Raw material viscosities can range from 200 cPs in outdoor storage tanks to 10 cPs during heated processing, then the margarine becomes a semisolid following interesterification or hydrogenation and cooling/crystallization. Specific gravity is only slightly less than water, in the range of 9.1 – 9.5.

Positive displacement pumps are commonly used to process oils into margarine, typically iron internal gear pumps for truck unloading and tank farm transfer of oils, with hygienic stainless steel lobe or circumferential piston pumps for processing. Positive displacement pumps enable high efficiency regardless of fluid viscosity and can even pump the semisolid margarine from cooling through kneading and working to packaging. Because flow rate is proportional to speed they can be easily controlled to match process speed. Hygienic design enables fast and easy clean-in-place or strip cleaning to ensure sanitization.

Custom Content One

Viking in the Process

Viking internal gear pumps are commonly used in edible oil processing facilities as well as margarine producers, from truck or railcar unloading to tank farm transfer, oil blending and refining (e.g. degumming, neutralization, bleaching and deodorization). Viking hygienic circumferential piston pumps are used in downstream processes from emulsification, cooling and crystallization to kneading and packaging.

Custom Content Two

Applications

- Raw material truck unloading, tank farm transfer

- Oil and margarine processing

Recommended Pumps

-

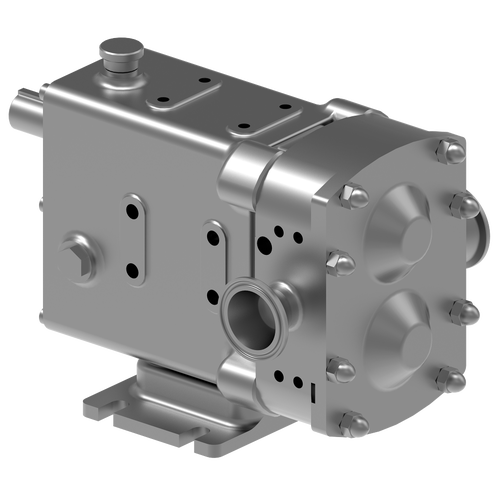

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

-

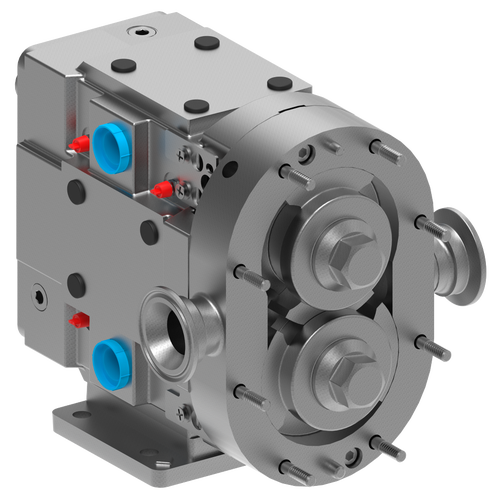

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

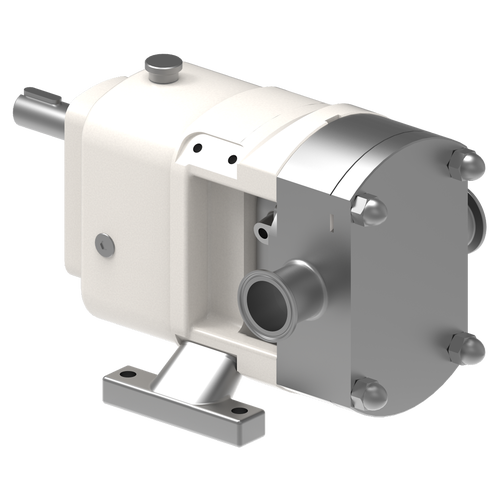

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025