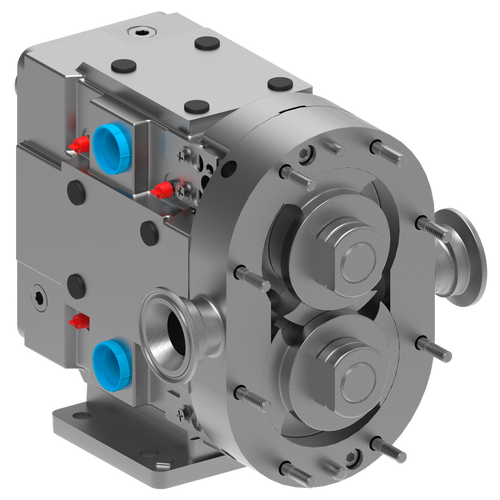

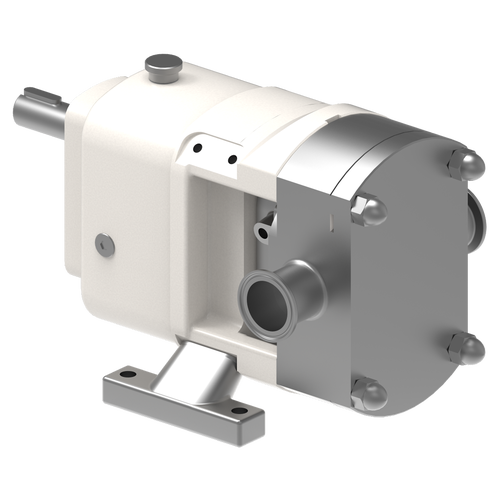

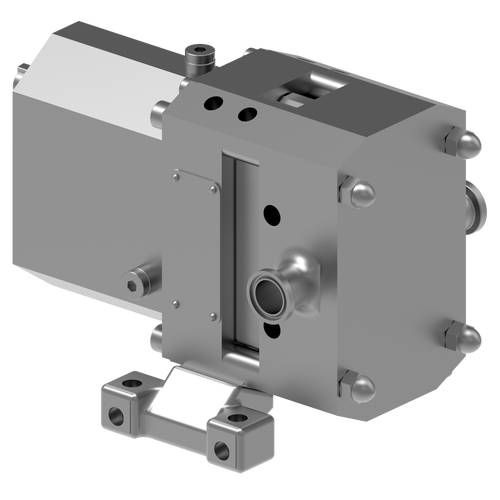

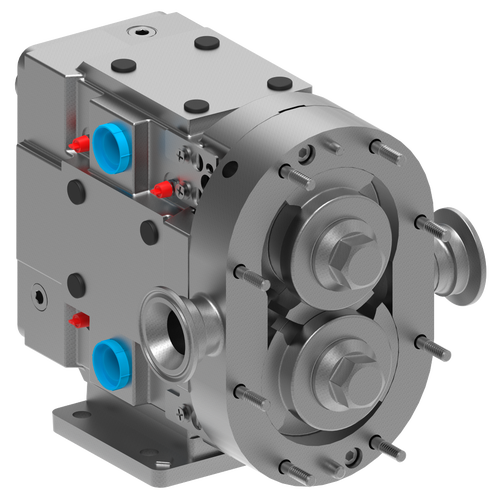

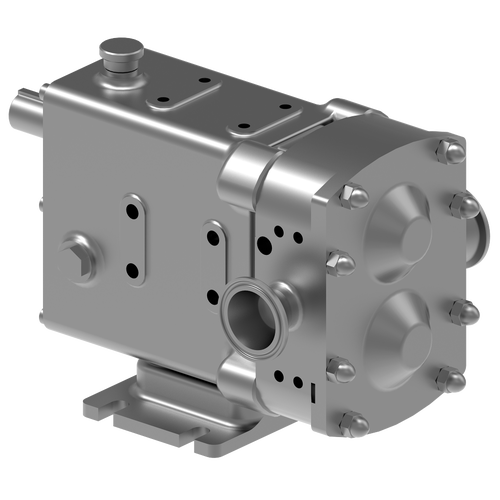

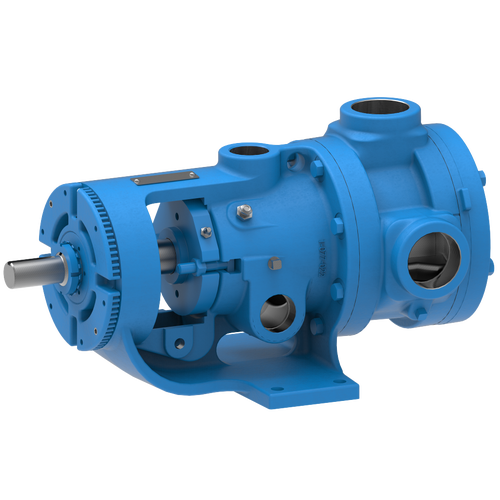

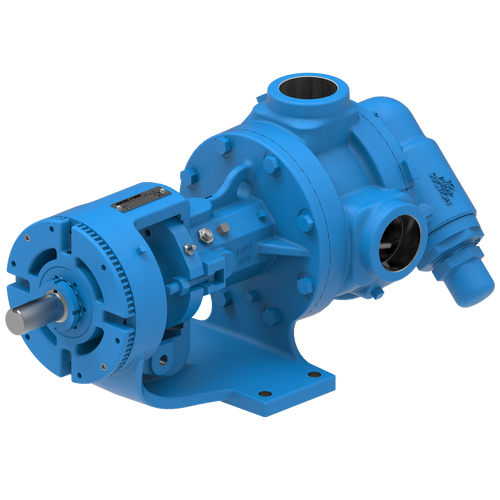

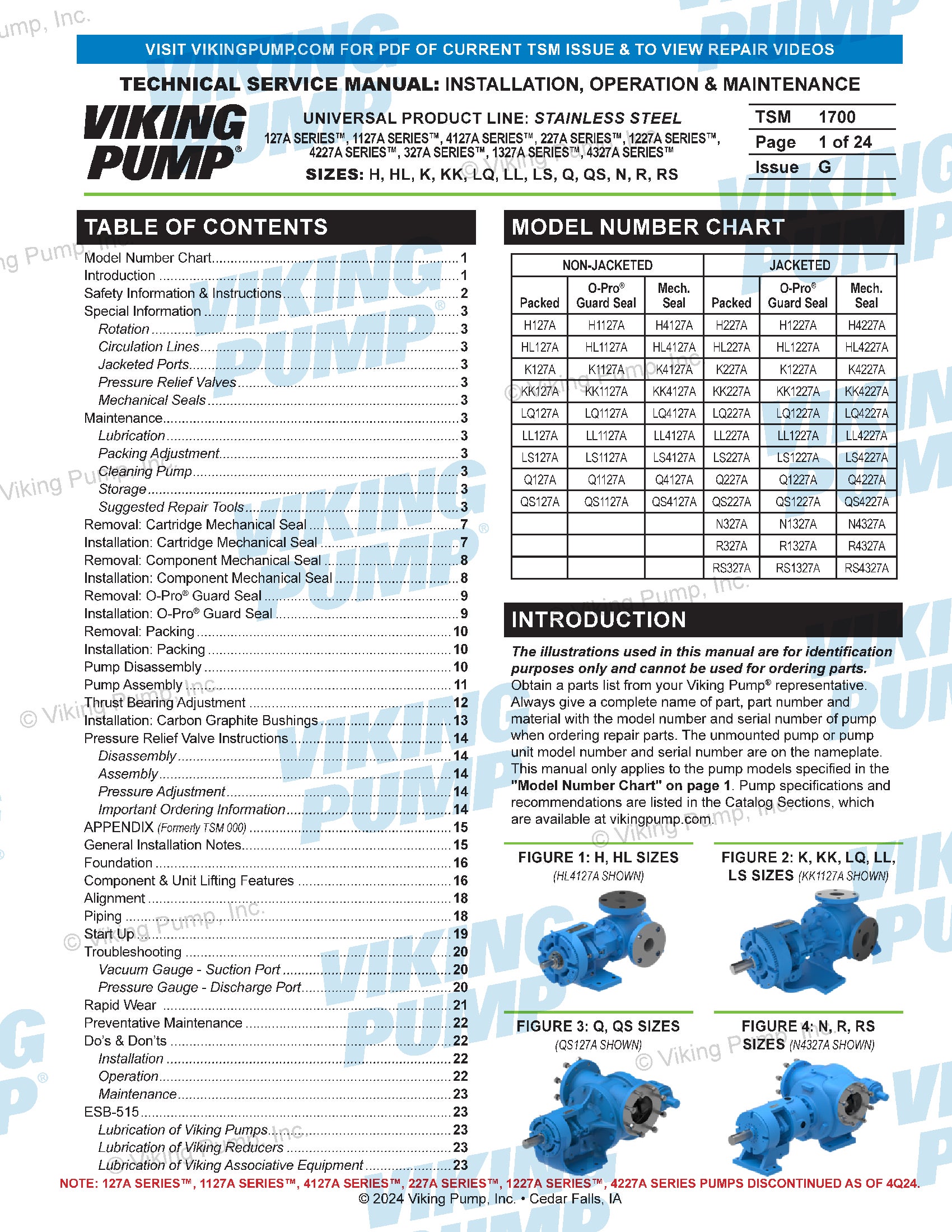

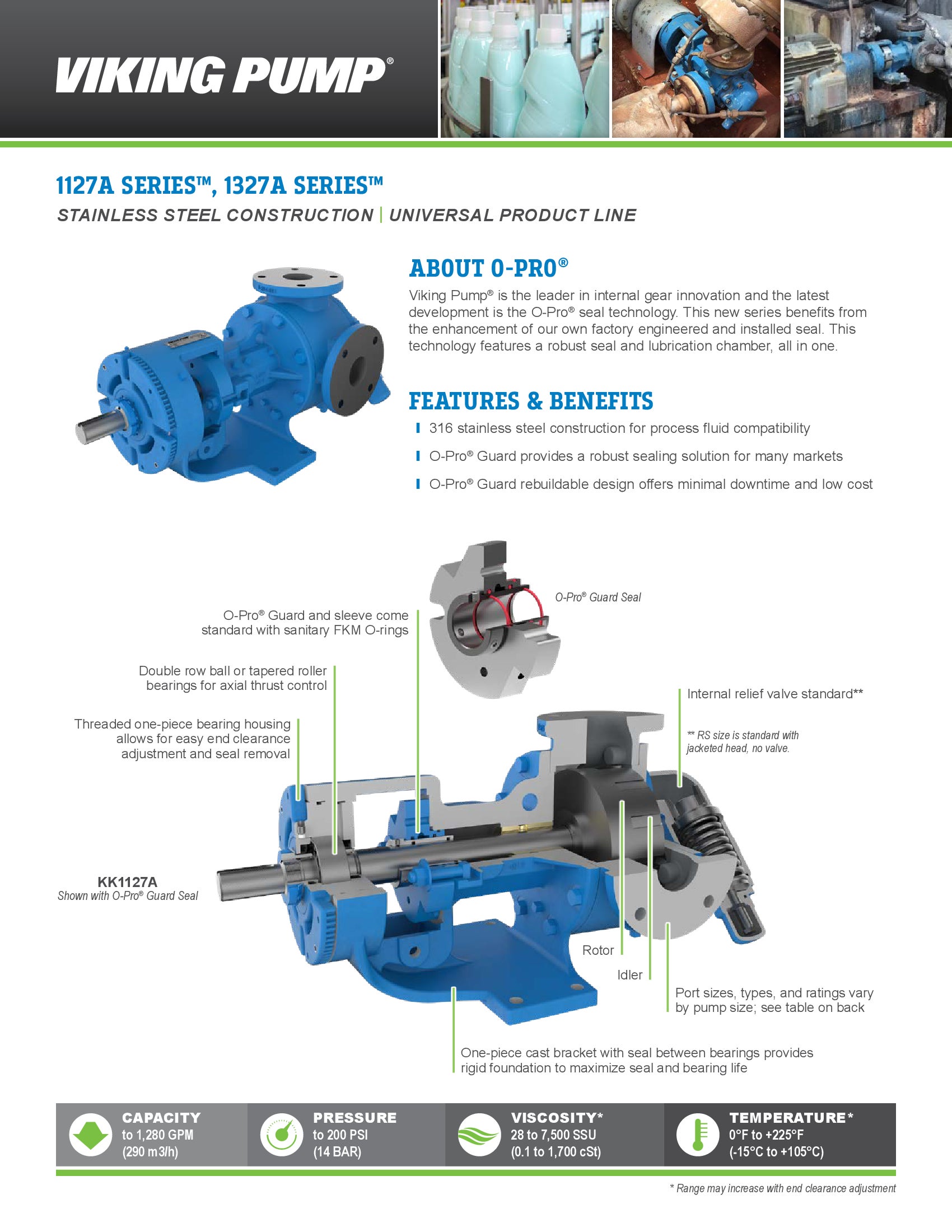

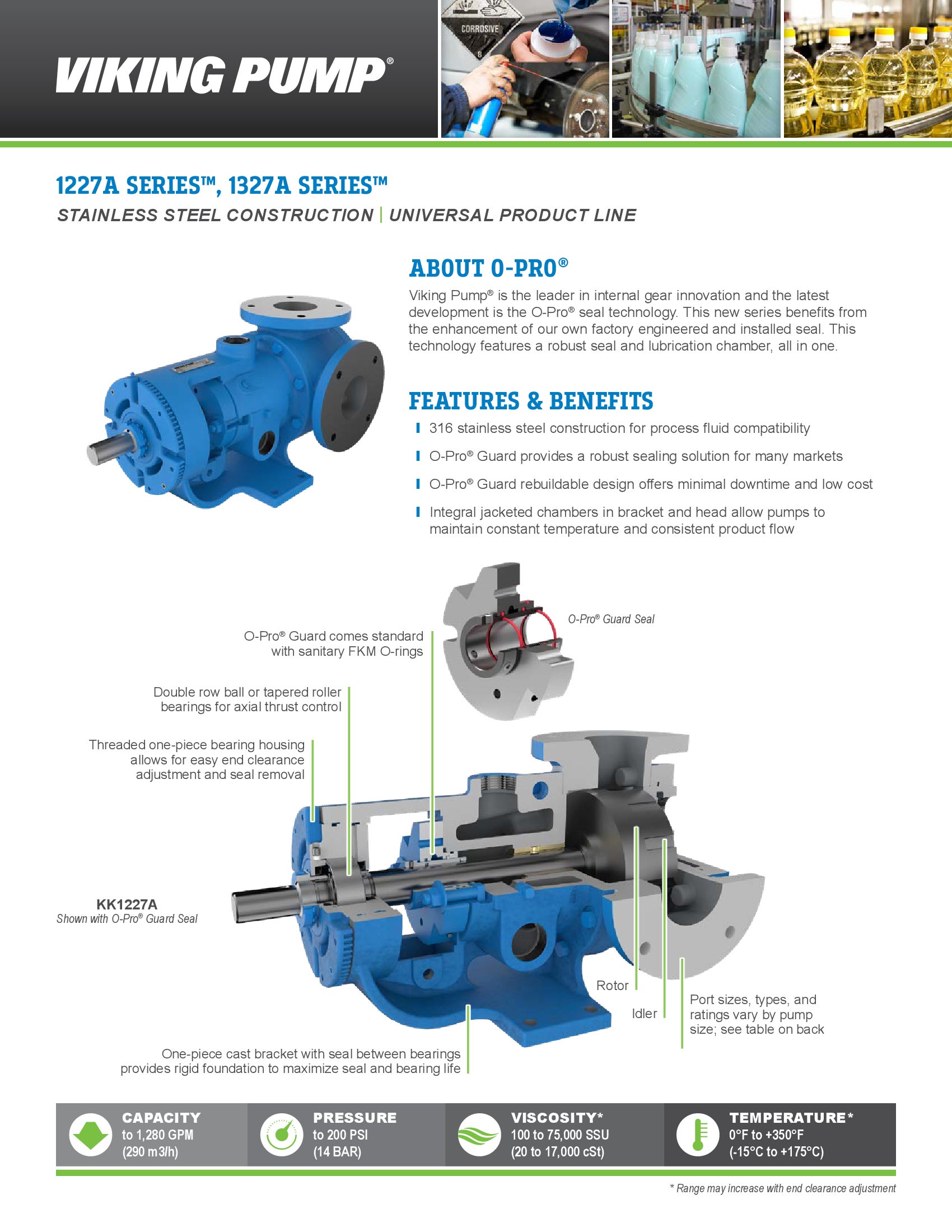

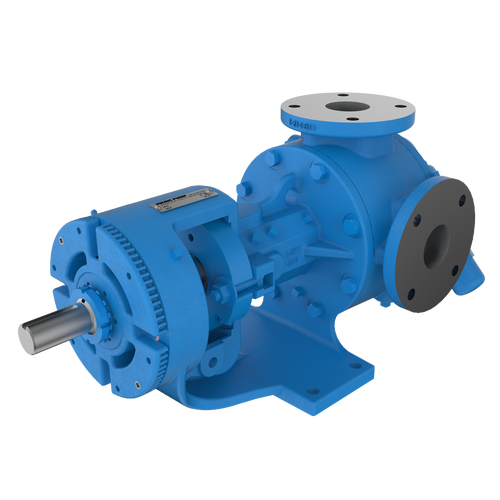

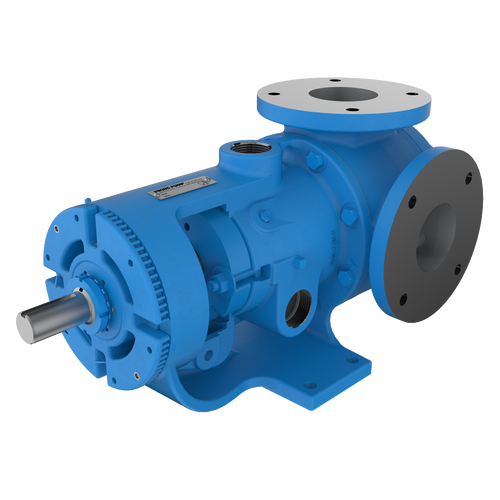

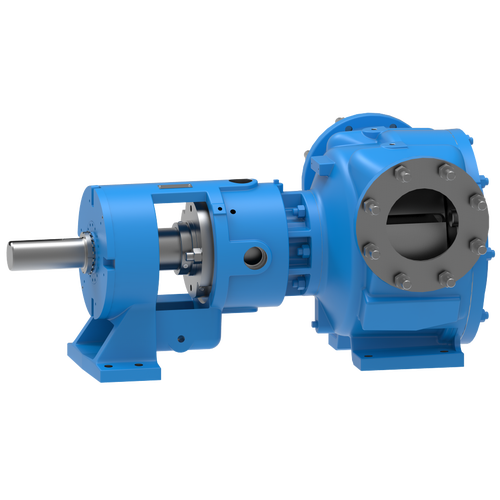

The 1327A Series™ internal gear pump with O-Pro® Seal technology is the perfect solution for peanut butter, paints & inks, edible oils, and more due to it's reliable sealing and easy maintenance. It can handle flows from 175 to 1,280 GPM (108 to 290 m³/h).

Features & Benefits

- 316 stainless steel construction for process fluid compatibility

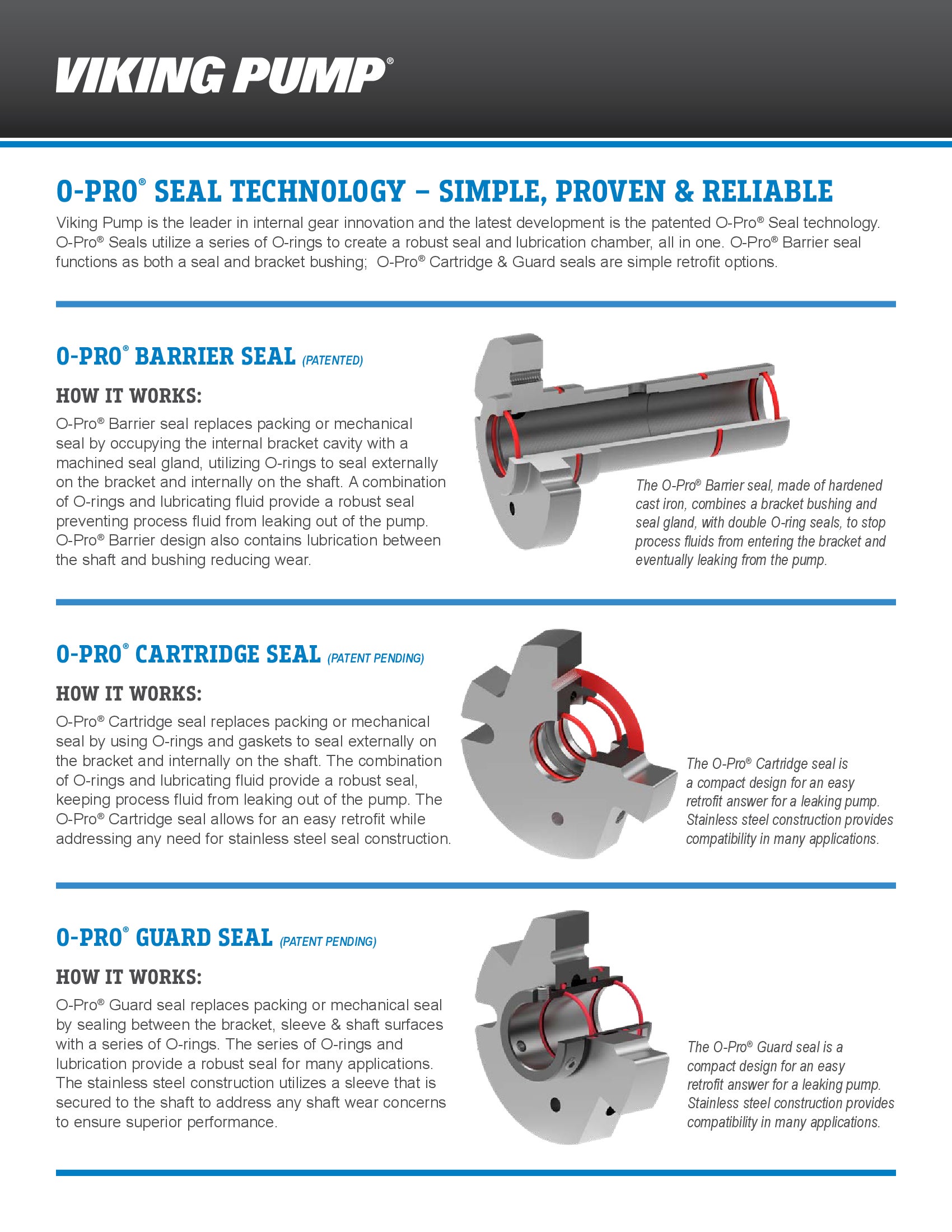

- O-Pro® Guard provides a robust sealing solution for many markets

- O-Pro® Guard rebuildable design offers minimal downtime and low cost

Capacity

175 to 1,280 GPM

108 to 290 m³/h

Viscosity

28 to 750 SSU

1 to 165 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

-15 to +225 °F

-25 to +105 °C

Options

Porting

Drives

Mounting

Sealing

Specifications

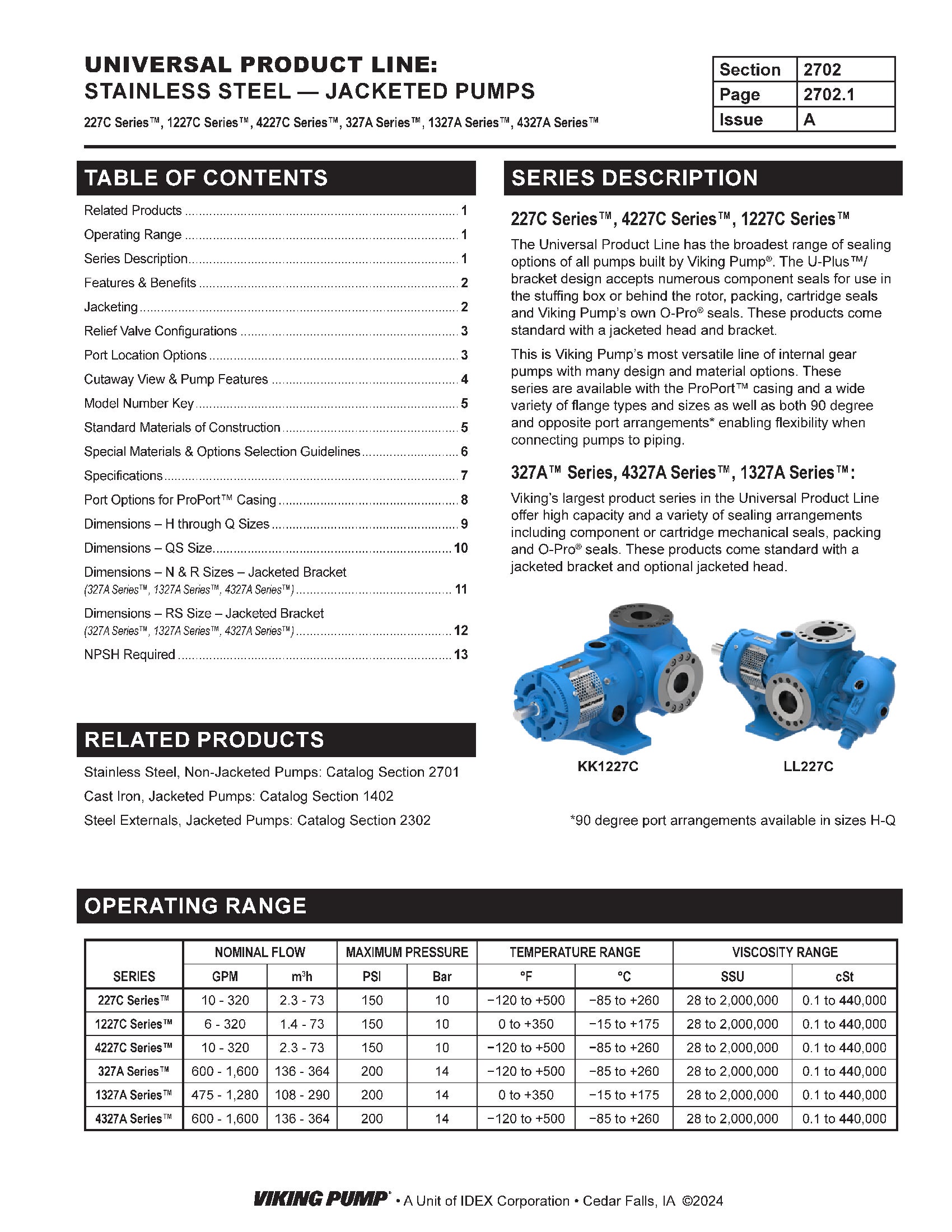

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| N1327A | 6 | 475 | 108 | 280 | 200 | 14 |

| R1327A | 8 | 880 | 200 | 225 | 175 | 12 |

| RS1327A | 10 | 1280 | 290 | 225 | 125 | 9 |

Videos

Soaps

Kettle soap, soap stock, soap skimmings, and liquid soap are a mixture of sodium salts of various fatty acids of natural oils and fats. Common soap is largely a mixture of the sodium salts of palmitic, stearic and oleic acids. Rosin soaps for laundry purposes are made by adding a soap made from rosin or rosin itself to an ordinary soap.

Detergent Gel

Detergent gels are surfactants used for their cleaning properties. These can be for laundry applications or used in dish washing and household cleaning activities.

Surfactants

Surfactants reduce the surface tension of the liquid in which they are dissolved. Commonly used in cleaning products to emulsify oils and hold dirt or other particulates in suspension. Also used in chemical processing like ethanol production.

Peanut Butter

Peanut butter is made from mixing ground up peanuts with various additives and fillers. From the mixer, peanut butter is pumped through a deaerator and/or heat exchanger to remove entrained air and drop the temperature prior to being pumped to the jar filling machines.

Paints

Paints are shear sensitive liquids that can have a variety of solvents & pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

-

REPAIR RESOURCES

Quick Tip #01 - Setting End Clearance on a Viking Pump Universal Seal Pump O-ring Replacement: O-Pro® Guard Seal How to Use a Thrust Bearing Locknut Tool Viking Pump Universal Seal Series with Stuffing Box Component Seals Repair Kit Installation Quick Tip #02 - Install Mechanical Seal into Stuffing Box in Viking Pump Universal Seal Pump Viking Pump: Converting to the O-Pro® Guard Seal

-

DRAWINGS

N with Jacketed Relief Valve - 6" Class 150 ANSI Opposite PDF

STEP

N with Plain Head - 6" Class 150 ANSI Opposite PDF

STEP

N with Relief Valve - 6" Class 150 ANSI Opposite PDF

STEP

R324A with Relief Valve - 8" Class 125 ANSI Opposite PDF

STEP

RS323A with Jacketed Head - 10" Class 150 ANSI Opposite PDF

STEP