Detergent Gel

Detergent Gel

Custom Content One

Detergent gels are concentrated surfactant-based liquids for laundry applications, dishwashing and household cleaning activities.

Detergent gels were developed as more concentrated versions of liquid detergents to reduce package size and weight for equivalent cleaning power. Some are packaged in PVA film pods that dissolve in the washing machine or dishwasher for added convenience. The higher concentration results in much higher viscosity, which varies by brand.

Hygienic positive displacement pumps are ideal for transferring detergent gel due to their ability to handle high viscosity fluids with precision and care, maintaining the quality and consistency of the product. These pumps operate by trapping fixed amounts of gel and moving it through the pump in a controlled manner, minimizing the risk of shear and ensuring smooth flow without compromising the structure of the detergent. The design of hygienic positive displacement pumps also enables easy cleaning. Their robust construction and gentle handling make them perfect for managing the unique challenges posed by detergent gels, offering efficiency and reliability in various manufacturing processes.

Custom Content One

Viking in the Process

While Viking gear pumps are typically used for manufacturing the base surfactants, Viking hygienic pumps are commonly used in final processing and blending of the surfactants with other ingredients, such as enzymes, fabric softeners and fragrances. Chemical thickeners may be added, or these materials may be pumped from blending tanks to heated evaporation tanks to concentrate the gel, then through heat exchangers for cooling. The finished product is pumped to packaging machines. Pumps and systems may be cleaned in place periodically to maintain hygiene.

Custom Content Two

Applications

- Ingredient Metering

- Product Transfer

Recommended Pumps

-

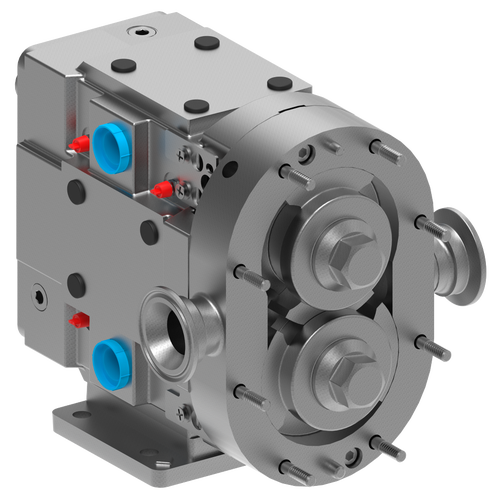

STERILOBE® SERIES

- Stainless Steel

- Mechanical Seal

- up to 753 gpm | up to 171 m3h

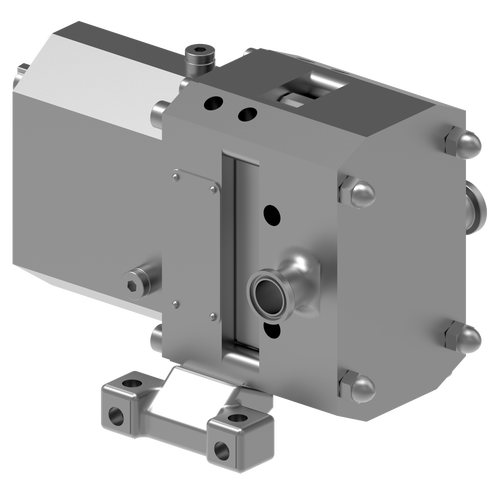

-

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

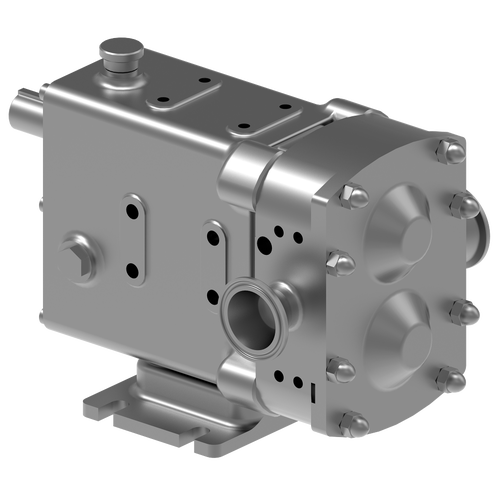

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

50 States / 50 Pumping Applications: Connecticut, Florida, Illinois, Missouri, and WashingtonSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Connecticut, Florida, Illinois, Missouri, and Washington.February 28, 2025

50 States / 50 Pumping Applications: Connecticut, Florida, Illinois, Missouri, and WashingtonSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Connecticut, Florida, Illinois, Missouri, and Washington.February 28, 2025