Caramel

Caramel

Custom Content One

Caramel is produced by heating sugar and other ingredients which is then used as a food or confectionary ingredient.

Caramel recipes range from a simple blend of sugar and water to more complex versions with added molasses, corn syrup, milk or cream, flavorings and other ingredients. The heating of the mixture, to about 245ᵒF (118ᵒC) results in caramelization where the sugar molecules react with atmospheric oxygen and combine to form larger molecules. These large brown molecules are what give caramel its color, viscosity and its stickiness. Further heating to about 290ᵒF (143ᵒC) results in a harder candy known as toffee.

Hygienic positive displacement pumps are ideal for manufacturing caramel due to their ability to handle viscous and sticky substances with precision and care. Unlike centrifugal pumps, which rely on high-speed rotation that can introduce air and cause unwanted crystallization in caramel, positive displacement pumps gently transfer the product, preserving its texture and consistency. These pumps are designed with smooth, easy-to-clean surfaces, which minimize the risk of contamination and ensure compliance with strict food safety standards, particularly when dairy products are added. Moreover, they provide precise flow control, enabling manufacturers to maintain consistent quality and measure ingredients accurately, crucial for crafting the perfect caramel. Their robustness and reliability make them a preferred choice in the food industry, where hygiene and product integrity are paramount.

Custom Content One

Viking In the Process

While sugar magma alone doesn’t support bacterial growth and gear pumps may be used, the addition of water, certain corn syrups, dairy products and other ingredients requires the use of cleanable hygienic pumps and systems for caramel. In large commercial caramel operations, Viking hygienic pumps are used to meter corn syrup and dairy products to the browning kettle, as well as to transfer finished caramel from the kettle to extrusion machines or further processing. This may include feeding a machine where caramel is layered into chocolate candy, or spray coating popcorn in a tumbler, or feeding a dip tank for caramel apples or other coated products. Use of heating jackets on the pumps and piping reduces product setup between batches.

Custom Content Two

Applications

- Metering ingredients

- Caramel transfer

Recommended Pumps

-

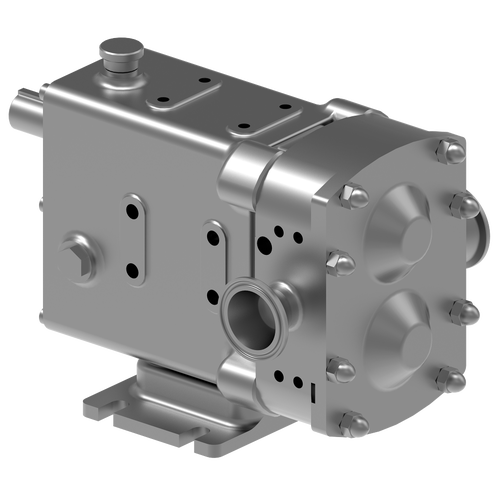

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

-

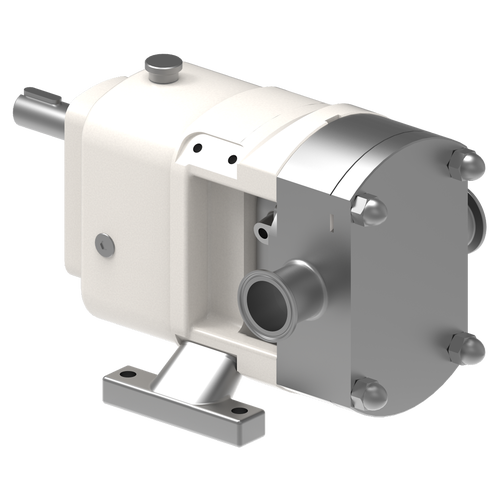

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

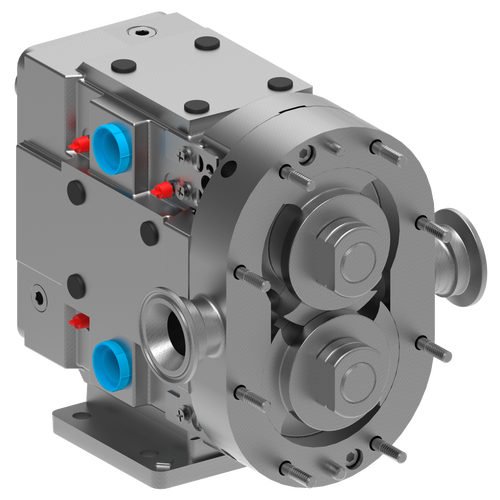

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025