Brine

Brine

Custom Content One

Brines are typically water with dissolved salt and sometime other additives. Brines have many applications, including as an anti-icing agent for roads by depressing the freezing point; as a safer (though less efficient) industrial refrigerant; for hydraulic fracturing in the oil and gas industry to stabilize boreholes and prevent formation collapse; and in food processing as a preservative, include pickling vegetables, curing meats, and preserving fish, extending their shelf life while also enhancing flavor.

Hygienic positive displacement pumps are an ideal choice for transferring brine used in preservation processes without compromising their integrity. These pumps ensure that the brine, which plays a crucial role in inhibiting microbial growth and enhancing the flavor and texture of preserved foods, is transferred smoothly and efficiently. Their gentle pumping action and precise flow control make them suitable for maintaining the consistency and quality of the brine solution, which is essential in preserving the sensory and nutritional attributes of food products. Additionally, hygienic positive displacement pumps are designed to meet stringent sanitary standards, making them easy to clean and maintain, thereby preventing any contamination and ensuring food safety during the preservation process.

Brines are simply solutions of water and salt, usually sodium, calcium, magnesium or potassium chloride. They are made to many different concentrations depending on the application, commonly ranging from about 5% to about 26% salt by weight, where it becomes a saturated solution. Viscosity is low, from about 1.1 to 1.3 cPs, so reduced clearances are recommended for highest efficiency. It’s important to note for NPSHa calculations that specific gravity also increases in proportion to the salt concentration, up to about 1.2 at that maximum concentration. Brines are also corrosive. When using higher brine concentrations, flushing the pump with clean water after brine use is recommended, even for corrosion resistant stainless steel pumps.

Custom Content One

Viking In the Process

Viking hygienic pumps are used in the food processing industry to transfer brine from makedown tanks to brining vats or directly to packaging machines where jars containing food products have brine added prior to sealing.

Custom Content Two

Applications

- Brine Transfer

Recommended Pumps

-

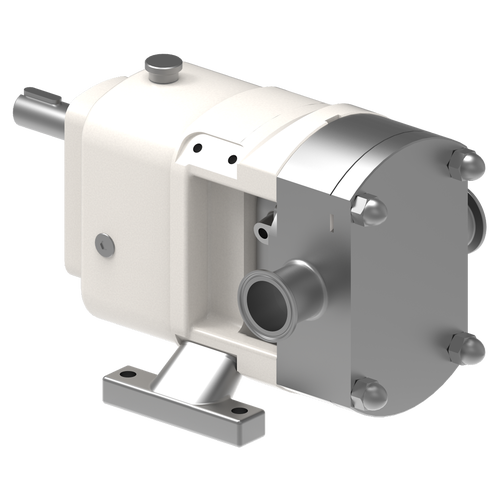

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

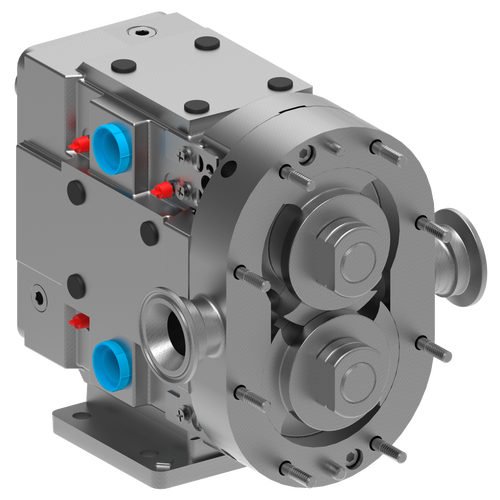

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025