Salmuera

Salmuera

Custom Content One

Las salmueras suelen ser agua con sal disuelta y, en ocasiones, otros aditivos. Las salmueras tienen muchas aplicaciones, entre ellas como agente anticongelante para carreteras al reducir el punto de congelación; como refrigerante industrial más seguro (aunque menos eficiente); para la fracturación hidráulica en la industria del petróleo y el gas con el fin de estabilizar los pozos y evitar el colapso de las formaciones; y en el procesamiento de alimentos como conservante, incluyendo el encurtido de verduras, el curado de carnes y la conservación de pescado, lo que prolonga su vida útil y mejora su sabor.

Las bombas higiénicas de desplazamiento positivo son una opción ideal para transferir la salmuera utilizada en los procesos de conservación sin comprometer su integridad. Estas bombas garantizan que la salmuera, que desempeña un papel crucial en la inhibición del crecimiento microbiano y la mejora del sabor y la textura de los alimentos conservados, se transfiera de forma fluida y eficiente. Su suave acción de bombeo y su preciso control del caudal las hacen adecuadas para mantener la consistencia y la calidad de la solución de salmuera, lo cual es esencial para preservar las propiedades sensoriales y nutricionales de los productos alimenticios. Además, las bombas higiénicas de desplazamiento positivo están diseñadas para cumplir con estrictas normas sanitarias, lo que las hace fáciles de limpiar y mantener, evitando así cualquier contaminación y garantizando la seguridad alimentaria durante el proceso de conservación.

Las salmueras son simplemente soluciones de agua y sal, normalmente cloruro de sodio, calcio, magnesio o potasio. Se elaboran en muchas concentraciones diferentes dependiendo de la aplicación, que suelen oscilar entre un 5 % y un 26 % de sal en peso, donde se convierte en una solución saturada. La viscosidad es baja, de entre 1,1 y 1,3 cPs, por lo que se recomienda reducir las holguras para obtener la máxima eficiencia. Es importante tener en cuenta para los cálculos de NPSHa que la gravedad específica también aumenta en proporción a la concentración de sal, hasta aproximadamente 1,2 en esa concentración máxima. Las salmueras también son corrosivas. Cuando se utilizan concentraciones de salmuera más altas, se recomienda enjuagar la bomba con agua limpia después de su uso, incluso en el caso de las bombas de acero inoxidable resistentes a la corrosión.

Custom Content One

Viking en el proceso

Las bombas higiénicas Viking se utilizan en la industria de procesamiento de alimentos para transferir salmuera desde tanques de preparación a cubas de salmuera o directamente a máquinas de envasado, donde se añade salmuera a los frascos que contienen productos alimenticios antes de sellarlos.

Custom Content Two

Aplicaciones

- Transferencia de salmuera

Recommended Pumps

-

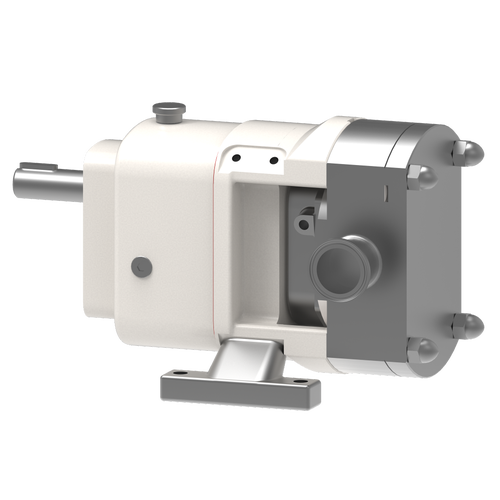

CLASSIC+ SERIES™ / MULTIPUMP® SERIES

- Acero inoxidable

- Sello mecánico

- up to 832 gpm | up to 189 m3h

-

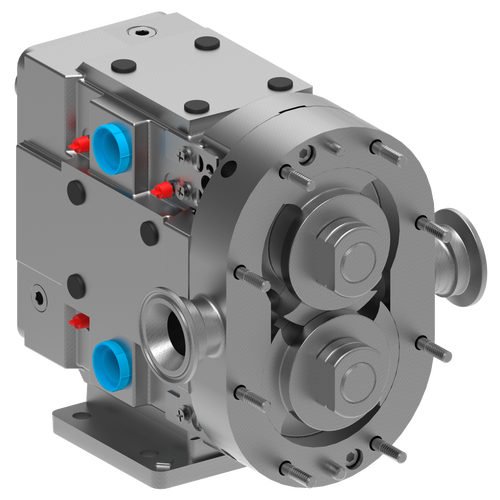

TRA®10 SERIES

- Acero inoxidable

- Sello mecánico

- up to 450 gpm | up to 102 m3h