Beer Yeast

Beer Yeast

Custom Content One

Key steps in brewing brewing beer include milling of the malted barley; mashing in a mash mixer, then separating wort from spent grain in a lauter tun where starches are converted to sugars; boiling in a brew kettle where hops is added; cooling in a heat exchanger, fermentation of wort into green beer, conditioning in a brite tank followed by filtration and packaging. Yeast is added to the cooled wort during the fermentation phase. While smaller craft brewers may add dry yeast directly into the fermentation vessel, industrial beer makers purchase fresh, active yeast solutions delivered when the beer is ready for fermentation.

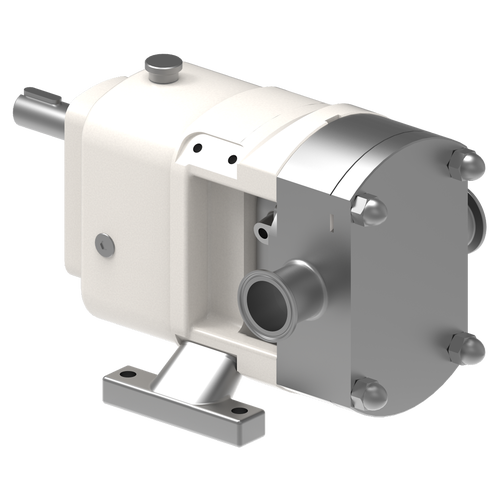

Hygienic positive displacement pumps are ideal for transferring beer yeast due to their ability to handle viscous and shear-sensitive fluids with precision and care. These pumps are specifically designed to maintain the quality and integrity of substances like beer yeast, which can easily be damaged or affected by high shear forces typical of other pump types. By using a slow, gentle pumping action, positive displacement pumps minimize shear, aeration and foaming, which is crucial for preserving the yeast’s viability and the beer’s taste profile. Additionally, their easy-to-clean design meets stringent sanitary standards, ensuring that the brewing process remains contamination-free while maintaining the perfect environment for yeast to thrive. This combination of gentle handling and hygienic design makes them the preferred choice for brewers looking to optimize their production process while maintaining the highest quality product.

Custom Content One

Viking in the Process

Because preventing microbial contamination and contamination from wild yeast is critical to beer making, Viking hygienic pumps may be used throughout the process, from transferring wort to finished beer. Dosing of fresh, active yeast solution into the fermentation tanks is a unique application requiring gentle handling to prevent damage to shear-sensitive, growing yeast. Viking hygienic pumps are used to ensure prevention of external contaminants from reaching the fermenter, while ensuring a healthy population of active yeast is available to ferment the beer.

Custom Content Two

Applications

- Transfer

- Metering

Recommended Pumps

-

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025