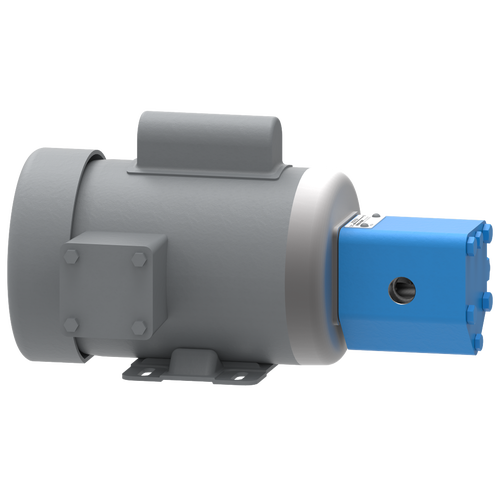

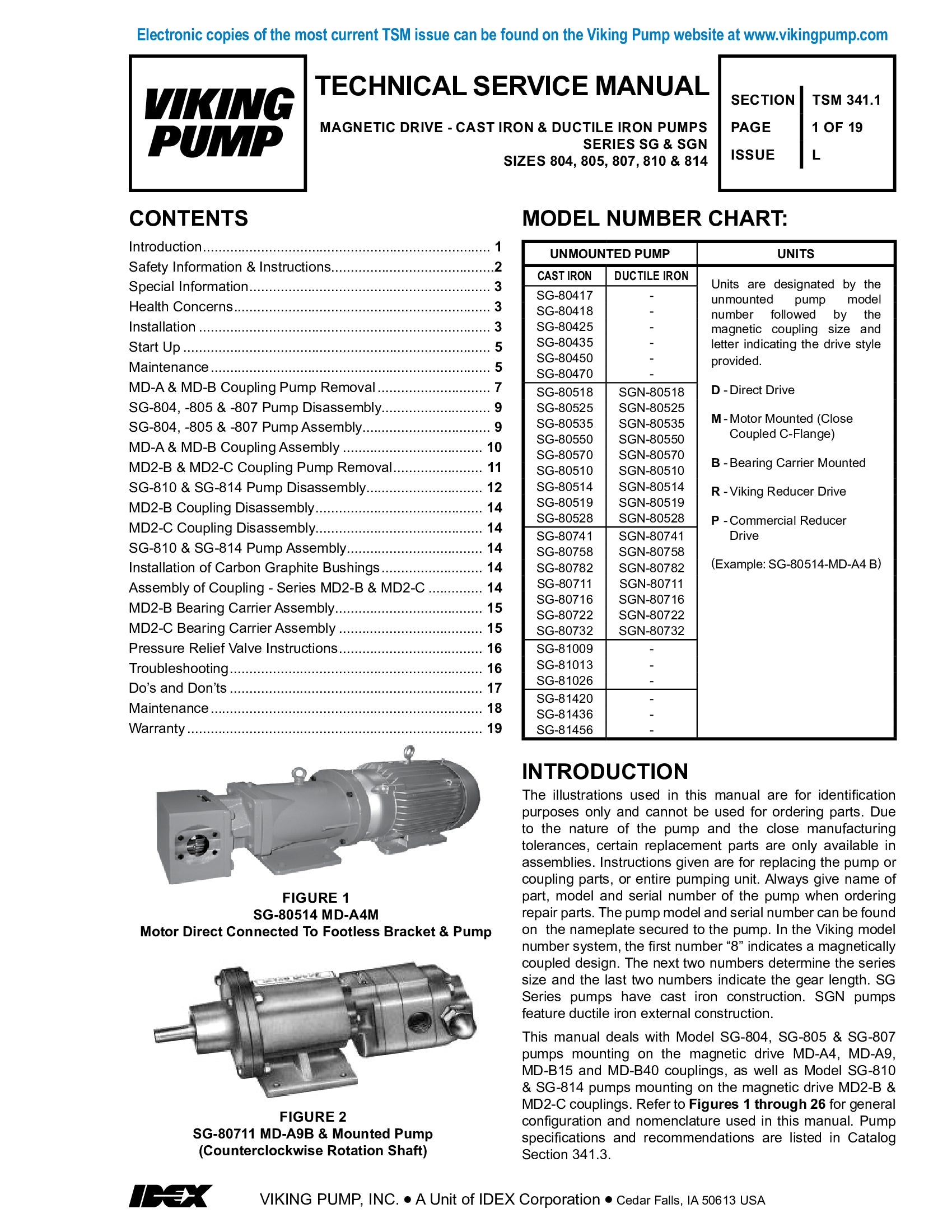

The SG-805 Series™ sealless external gear pump is designed for applications where shaft seal leakage is unacceptable. This mag drive pump offers a hermetically sealed solution using magnet drive technology which eliminates traditional shaft seals and associated issues like wear, leakage, and air infiltration. It can handle flows up to 11.2 GPM (2.54 m³/h).

Features & Benefits

- Leak-Free Operation: Hermetically sealed design eliminates shaft seals, preventing leakage and air infiltration—ideal for hard-to-seal or hazardous liquids.

- Low Maintenance: Magnetic drive system reduces wear and eliminates seal-related maintenance, improving reliability and uptime.

- Enhanced Cooling & Flow: Hollow shaft enables internal fluid circulation for magnet cooling and product movement, preventing stagnation and ensuring consistent performance.

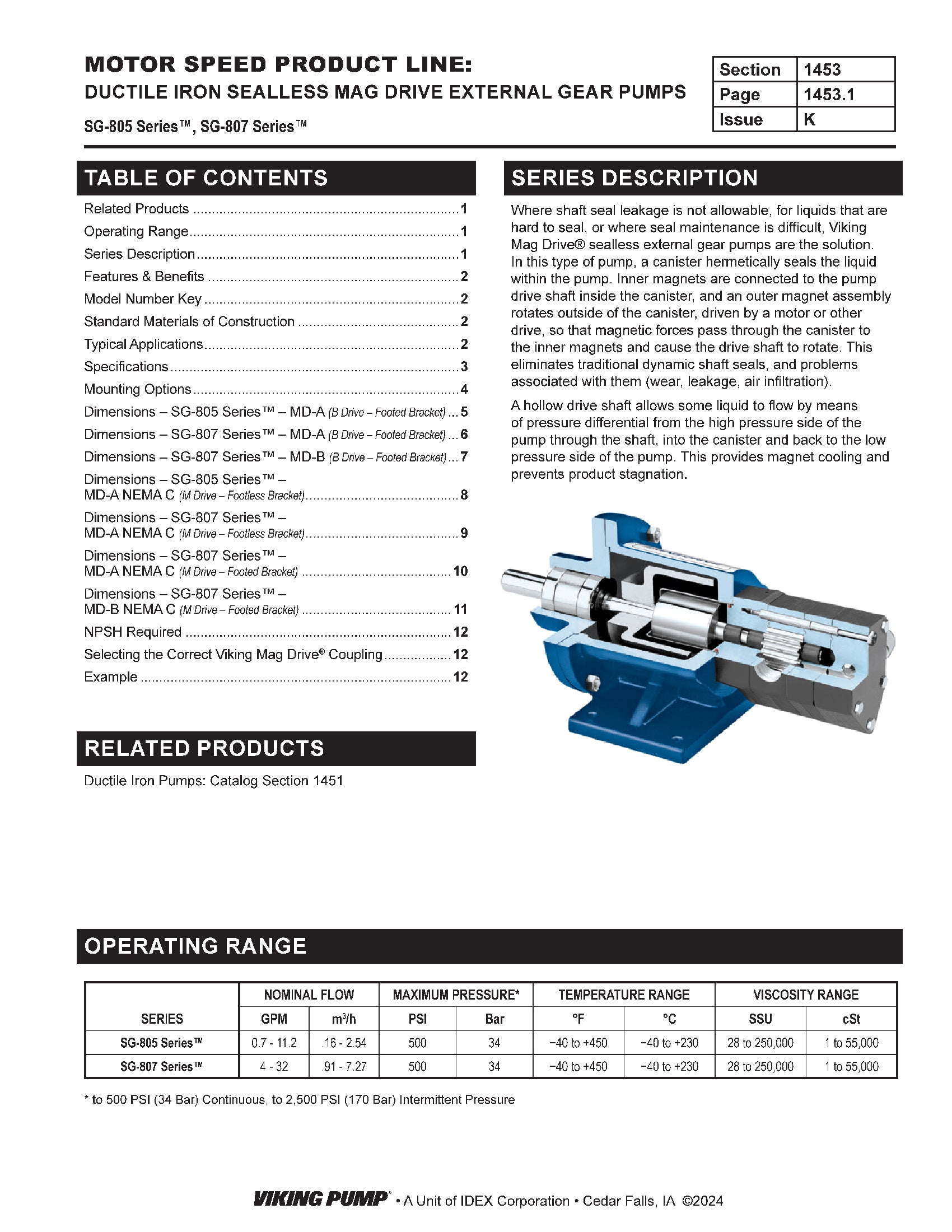

Capacity

0.7 to 11.2 GPM

0.16 to 2.54 m³/h

Viscosity

28 to 250,000 SSU

1 to 55,000 cSt

Pressure

500 PSI

34 BAR

Temperature

-40 to +450°F

-40 to +230°C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port (Inches) | Nominal Capacity At 1750 RPM (GPM) | Nominal Capacity At 1750 RPM (LPM) | Continuous Pressure* PSI | Continuous Pressure* BAR | Maxiumum Temp (F) | Maximum Temp. (C) |

|---|---|---|---|---|---|---|---|

| SG-80518 | 1/2 in NPT | 0.7 GPM | 0.16 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80525 | 1/2 in NPT | 1 GPM | 0.23 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80535 | 1/2 in NPT | 1.4 GPM | 0.32 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80550 | 1/2 in NPT | 2 GPM | 0.45 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80570 | 1/2 in NPT | 2.8 GPM | 0.64 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80510 | 1/2 in NPT | 4 GPM | 0.91 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80514 | 3/4 in NPT | 5.6 GPM | 1.27 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80519 | 3/4 in NPT | 7.6 GPM | 1.73 LPM | 500 PSI | 34 BAR | 225 F | 107 C |

| SG-80528 | 3/4 in NPT | 11.2 GPM | 2.54 LPM | 100 PSI | 7 BAR | 225 F | 107 C |

Videos

Biofuels

Biofuels include Biodiesel and Ethanol. These are fuels made from renewable resources and typically blended with refined fuels as additives.

Additives

Various liquids designed to enhance or change the properties of the bulk liquid such as fuels, greases, and oils. These additive liquids include antioxidants, rust inhibitors, anti-wear agents and viscosity modifiers.

Polyurethanes

Polyurethane foam is produced when a polyether is treated with a isocyanate in the presence of water and a catalyst, as well as fillers, dispersing and emulsifying agents, etc. The water reacts with the isocyanate group to cause cross linking and curing, and also produces carbon dioxide which causes foaming. May also be known as Isocyanate liquid.

Adhesives

Adhesives are a group of substances, such as cement, glue, mucilage, and paste that are capable of holding materials together by surface attachment. Adhesives are made from many different basic materials, among them dextrin, latex, silicones, liquid rubber, resin, sodium silicate, and starch.

Crude Oils

This is a very generic term for unrefined oils typically being recovered from the ground. Some crude oil may contain particulates from the oil well or recovery method. They are considered to be flammable liquids. Crude oils are later refined and used for everything from making plastics to gasoline.