Biofuels

Biofuels

Custom Content One

Positive displacement pumps are ideal for transferring biofuels due to their ability to handle a wide range of viscosities and provide consistent and precise flow rates. These pumps operate by trapping a fixed amount of fluid and then displacing it through the pump, making them particularly effective for the thicker, more variable nature of biofuels. This design ensures that the flow remains steady regardless of pressure changes, which is crucial for maintaining the integrity and efficiency of biofuel applications. Additionally, positive displacement pumps are typically more efficient and less susceptible to damage from particulate matter often found in biofuel mixtures, ensuring reliable and durable performance in demanding environments. Their capability to handle corrosive and abrasive fluids further enhances their suitability for biofuel transfer, setting them apart from other pump types.

Recommended Pumps

-

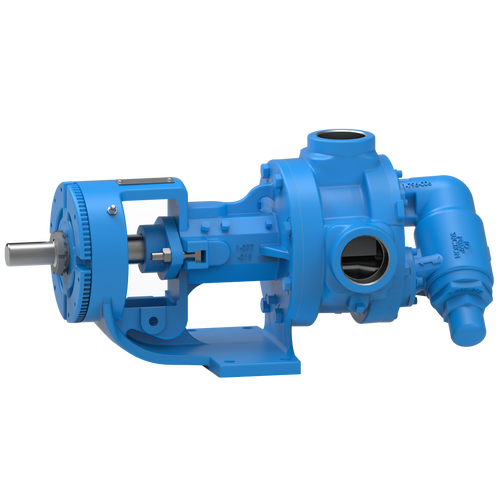

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

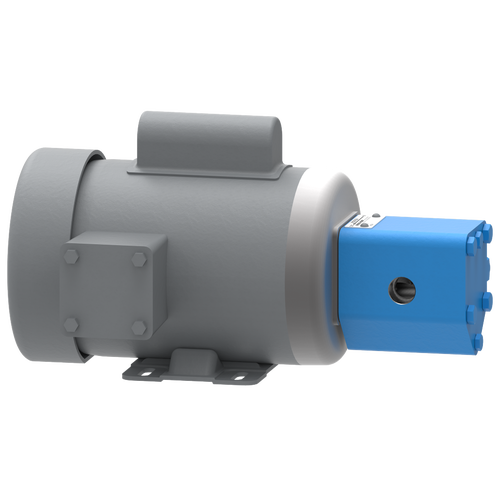

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

-

SG SERIES™

- Ductile Iron

- Mechanical Seal

- up to 190 gpm | up to 43 m3h

Articles / Case Studies

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025