Sugar Solution

Sugar Solution

Recommended Pumps

-

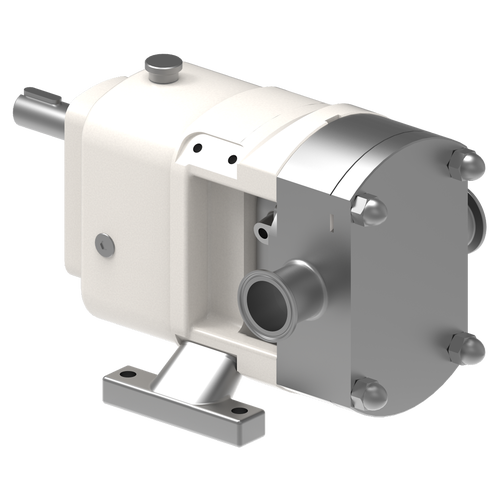

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

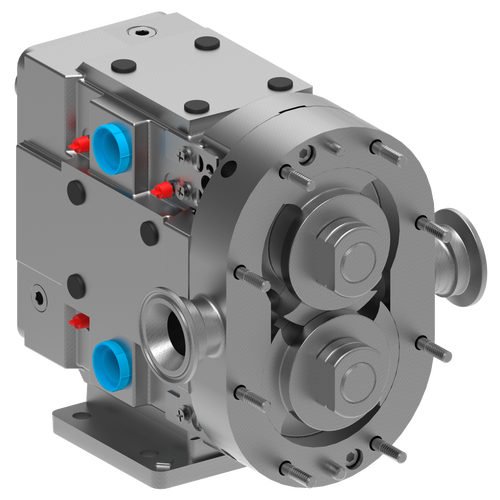

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

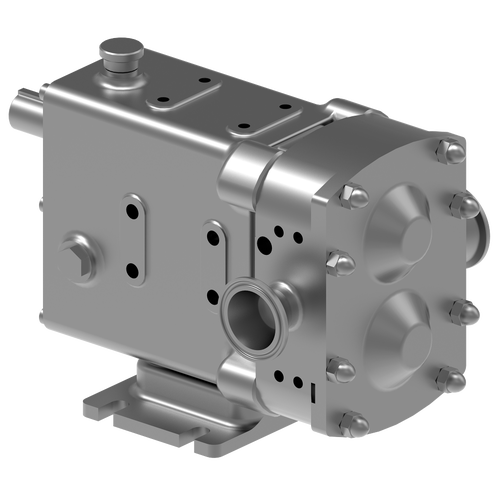

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Unlike most of my colleagues I didn’t start out with a mechanical background. While they were studying kinetics and machine design, I was studying digital electronics and industrial power. When I started my career in the world of pumps, I had to learn a whole new set of concepts. What was surprising was that while the terminology may be a bit different, the concepts are very similar. Think of the following as a “Rosetta Stone” for translating the common terms and concepts of fluid systems to your more familiar terms and concepts of electrical systems.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025