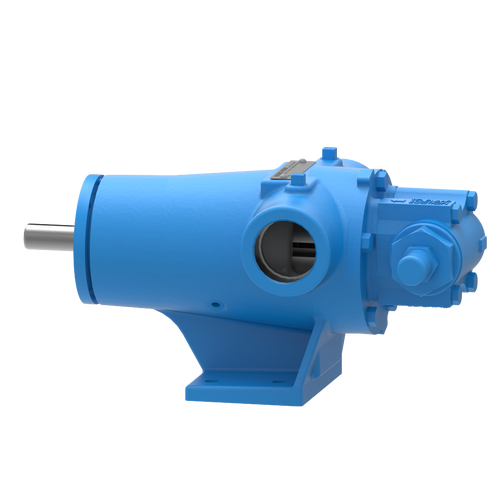

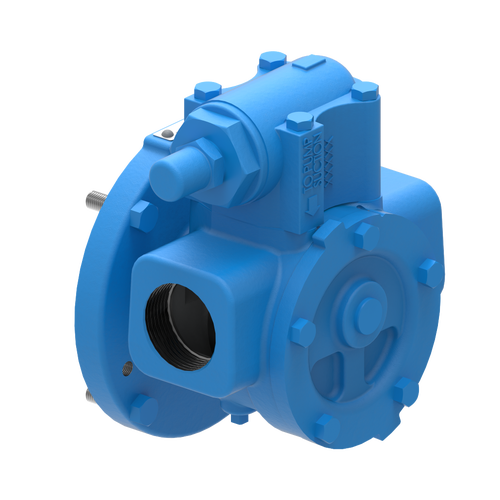

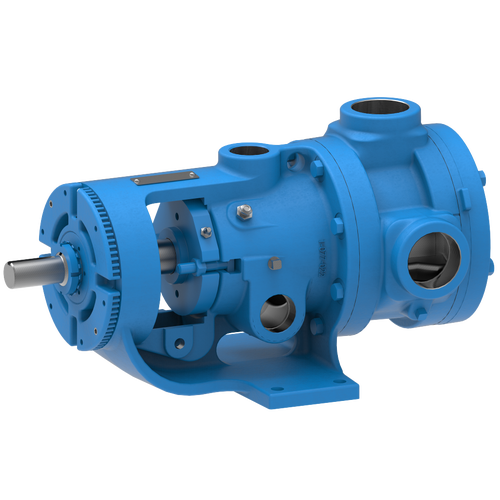

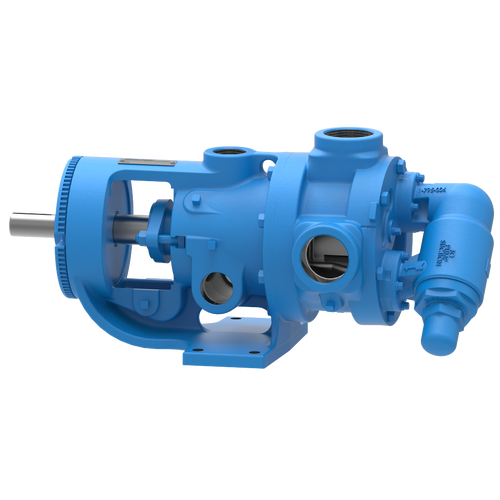

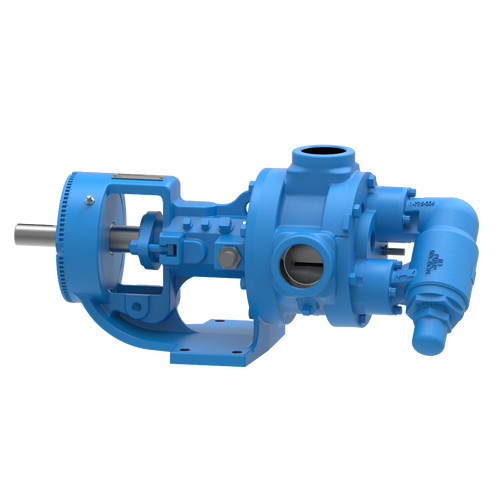

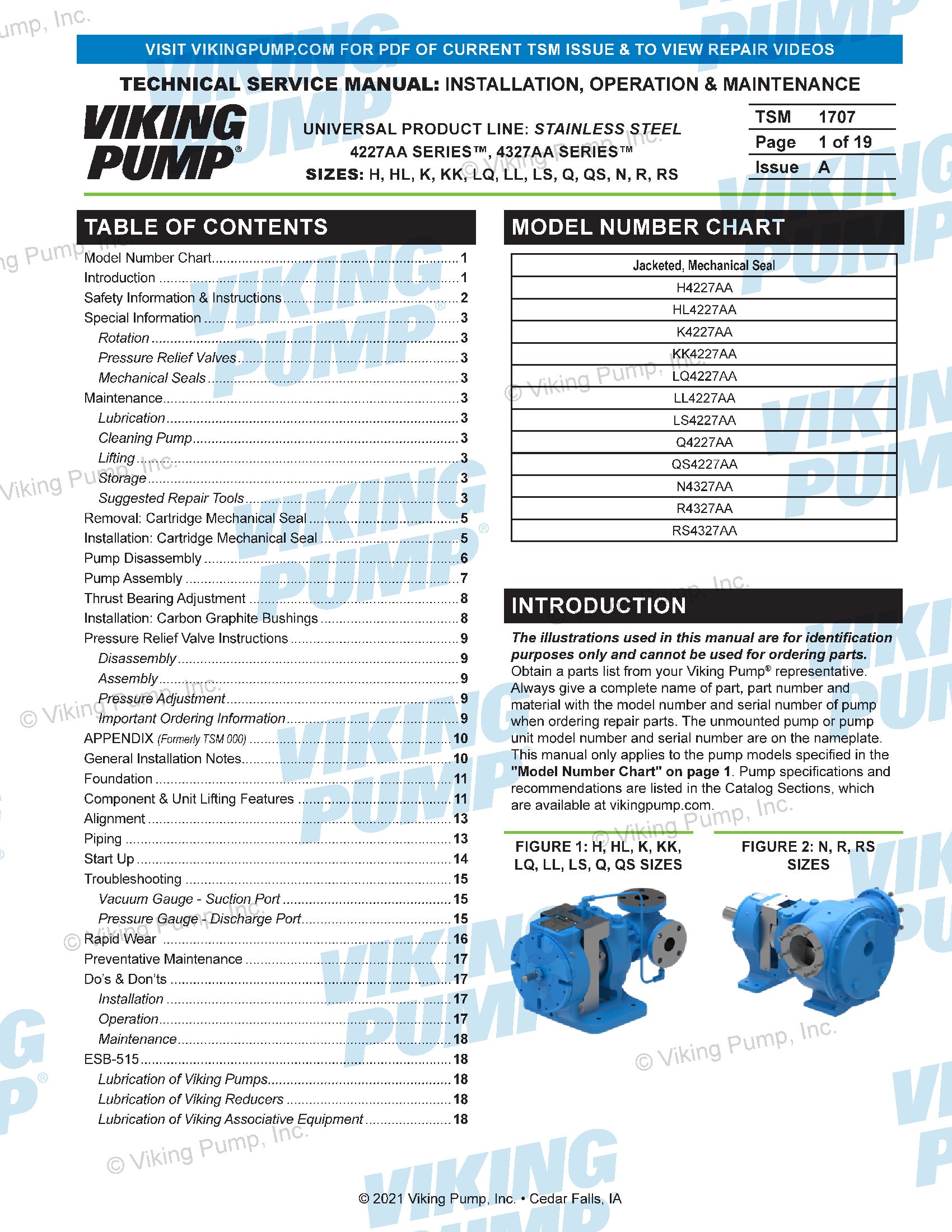

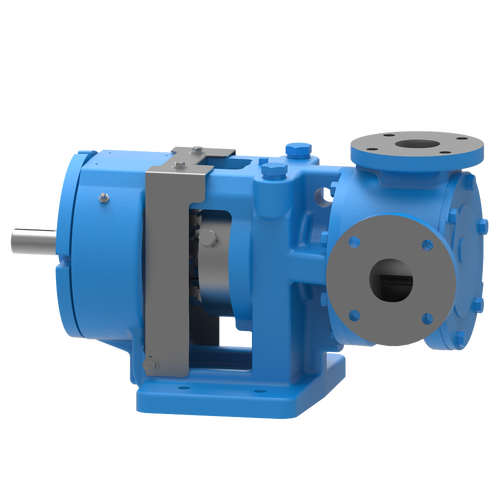

The 4227AA Series™ internal gear pump is the ideal solution for your oil and gas applications. This stainless steel option has 4 bolt mount API 682 cartridge seals with minor clarifications to the API 676 standard. It can handle flows up to 1,600 GPM (363 m³/h).

Features & Benefits

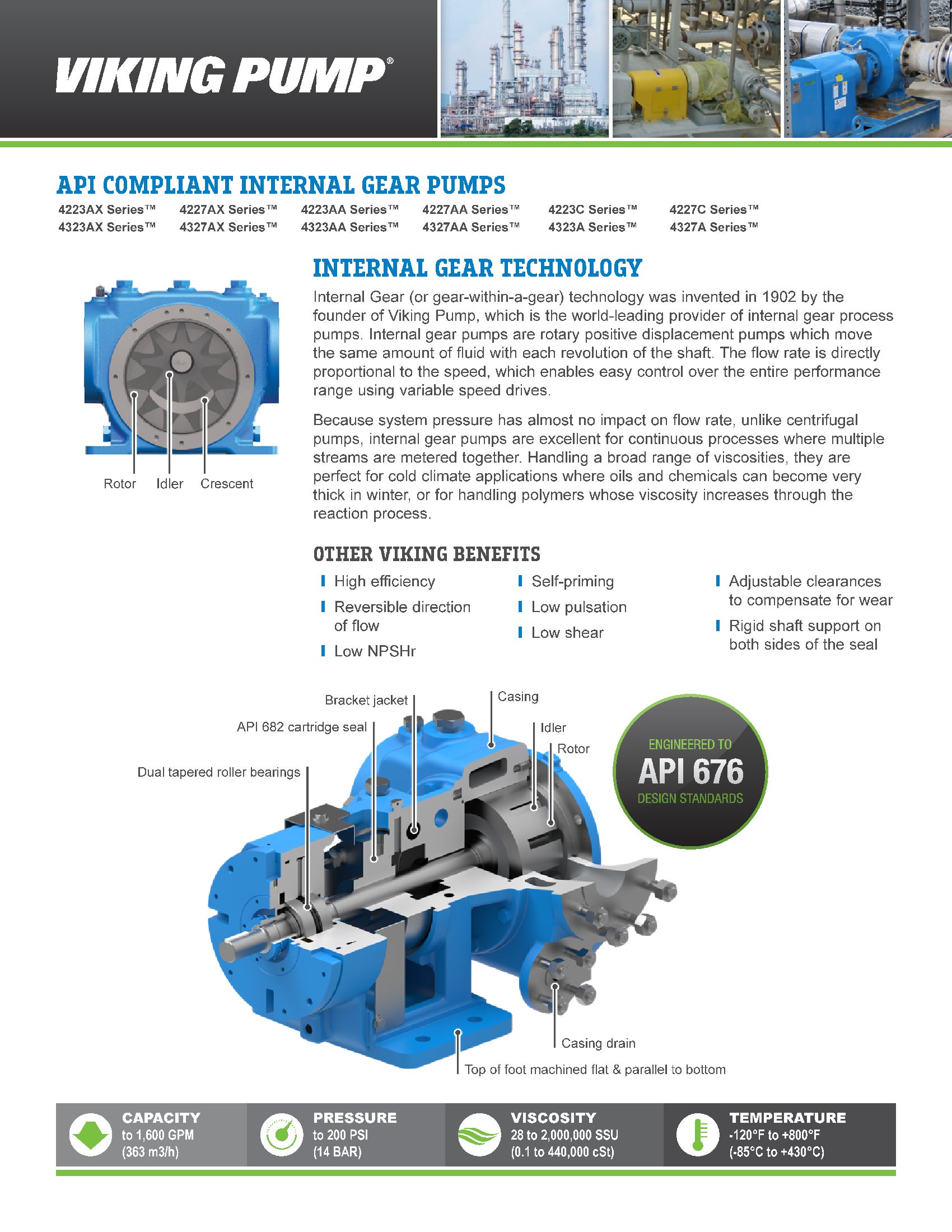

- Internal gear pumps are rotary positive displacement pumps which move the same amount of fluid with each revolution of the shaft

- Flow rate is directly proportional on the speed, which enables easy control over the entire performance range using variable speed drives

- System pressure has minimal impact on flow rate making this an excellent solution for continuous processes where multiple streams are metered together

Capacity

to 1,600 GPM

to 363 m³/h

Viscosity

28 zu 2,000,000 SSU

0.1 zu 440,000 cSt

Pressure

to 150 PSI

to 10 BAR

Temperature

-120°F zu +800°F

-85°C zu +430°C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H4223AA | 1.5 | 15 | 3.4 | 1750 | 200 | 14 |

| HL4223AA | 1.5 | 30 | 6.8 | 1750 | 200 | 14 |

| K4223AA | 2 | 80 | 18 | 780 | 200 | 14 |

| KK4223AA | 2 | 100 | 23 | 780 | 200 | 14 |

| LQ4223AA | 2.5 | 135 | 31 | 640 | 200 | 14 |

| LL4223AA | 3 | 140 | 32 | 520 | 200 | 14 |

| LS4223AA | 3 | 200 | 45 | 640 | 200 | 14 |

| Q4223AA | 4 | 300 | 68 | 520 | 200 | 14 |

| QS4223AA | 6 | 500 | 114 | 520 | 200 | 14 |

Crude Oils

This is a very generic term for unrefined oils typically being recovered from the ground. Some crude oil may contain particulates from the oil well or recovery method. They are considered to be flammable liquids. Crude oils are later refined and used for everything from making plastics to gasoline.

Lube Oil (Machinery Lubrication)

Machinery lubrication pumps are used in everything from small backup generators to naval ships. Lube oils, as the name implies, are the liquids used to lubricate rotating and reciprocating machinery. Lube oils may be handled at higher pressures to ensure their penetration of the equipment.

Diesel (#2 Fuel Oil)

Diesel is distilled from petroleum and is typically used in heavy equipment as fuel. While it is thin diesel is somewhat lubricating. It is typically handled in a bulk transfer application or on back-up generator skids.

Wax

Waxes can be natural secretions of plants or animals, such as beeswax, or by-products of petroleum refining. Wax is commonly used in the paper and boxboard industries to make products such as cartons and paper packaging moisture resistant. Wax can also help prevent food products from sticking to paper packaging.

Molten Sulfur

Molten Sulfur is a difficult to pump liquid due to the very narrow temperature range that it can be handled. Molten Sulfur is typically solid up to 240°F, and then re-solidifies again around 370°F. The suggested handling range is 270°F - 310°F, where the viscosity is 6 - 9 cP. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.