Ketchup

Ketchup

Custom Content One

Ketchup (catsup) is produced from tomatoes with the addition of vinegar, sugar, and spices. It is used as a condiment and as a basis for other sauces.

Ketchup is famously a non-Newtonian, thixotropic (shear-thinning) fluid, thick under static conditions, then when agitated the viscosity is reduced, returning to the viscous state when static again. Its viscosity ranges from up to 50,000 cPs while static to around 5,000 cPs when agitated, with specific gravity about 1.13. It is acidic, with a pH ranging from 3.6 to 3.9.

Ketchup may be made from fresh tomatoes or from concentrated tomato pulp or paste, with the addition of salt, sugar, vinegar, and spices according to each manufacturer’s recipe.

Hygienic positive displacement pumps are required for this highly viscous product. Their rotating lobes or circumferential pistons create large cavities that gently transport the tomato product through the pump with a minimum of shear stress. They are self-priming and can develop the high pressures needed to pass this viscous product through downstream piping and processes. They are made of stainless steel which is impervious to the low pH of ketchup. In addition, they can be easily cleaned in place or strip cleaned to maintain process hygiene. They are available with very high capacities and variable speed drives which allow simple flow rate control in proportion to the line speed.

Custom Content One

Viking in the Process

Viking hygienic pumps are used in the processing of ketchup from fresh, ripe tomatoes as well as from tomato paste. They pump tomato pulp from breaking through filtration, blending, homogenization and pasteurization to packaging. Or they pump paste through blending and pasteurization to packaging.

Custom Content Two

Applications

- Tomato processing and transfer

- Tomato paste transfer

- Ketchup processing and transfer

Recommended Pumps

-

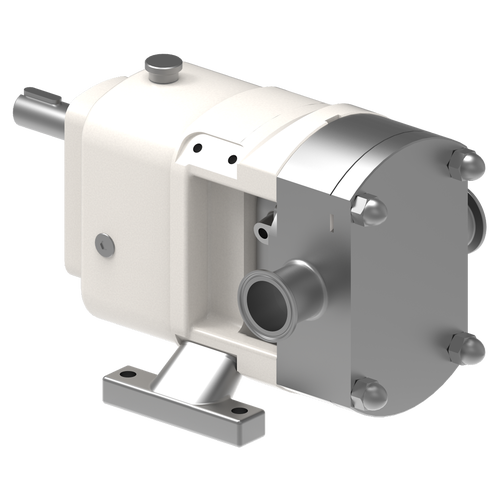

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

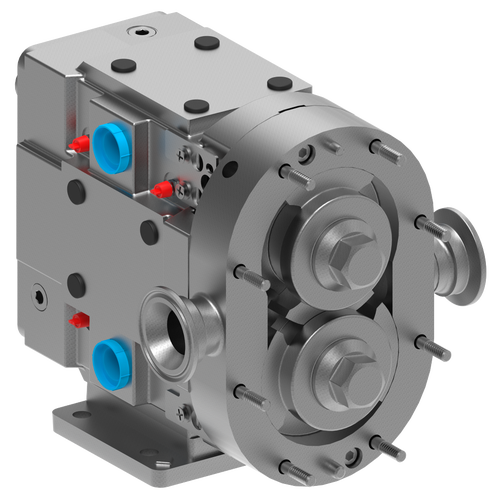

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

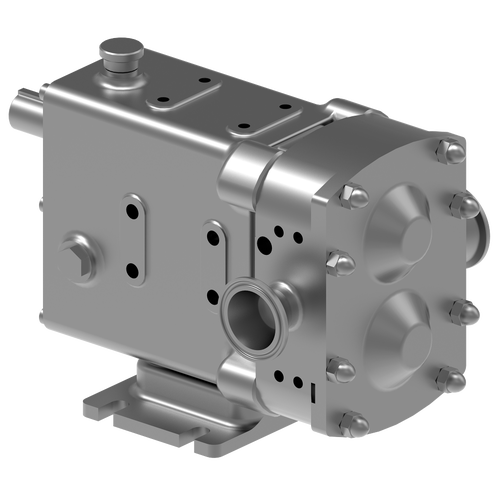

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025