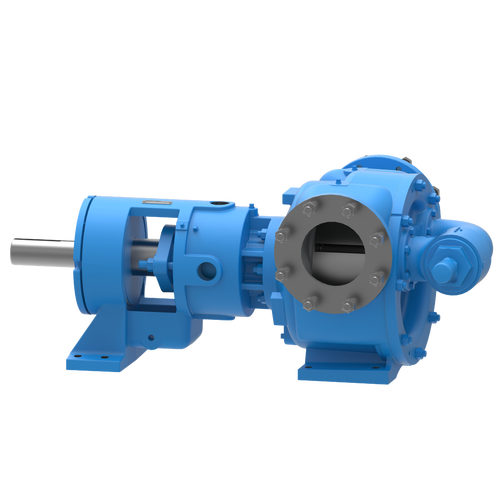

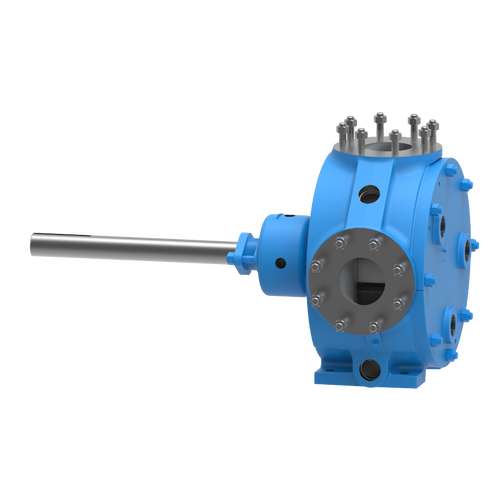

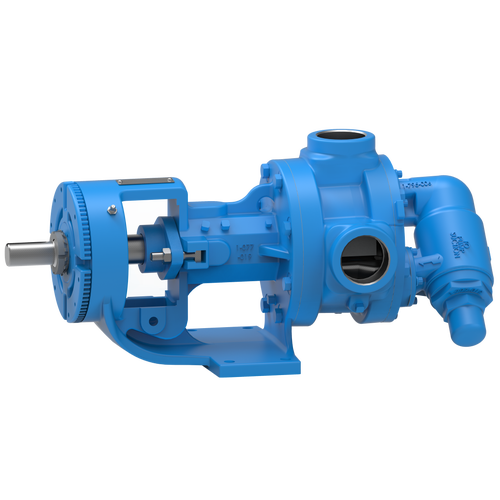

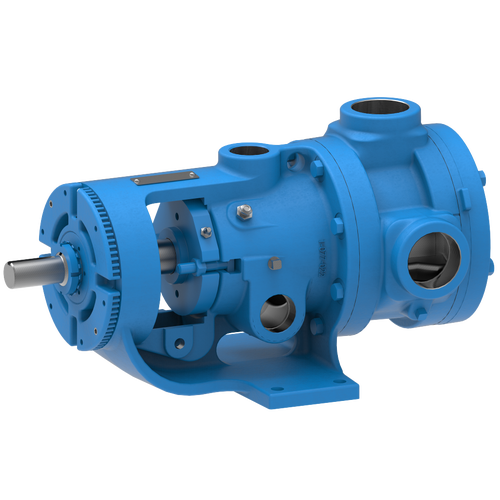

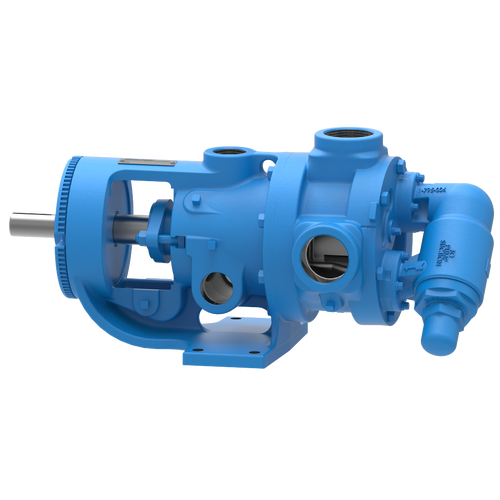

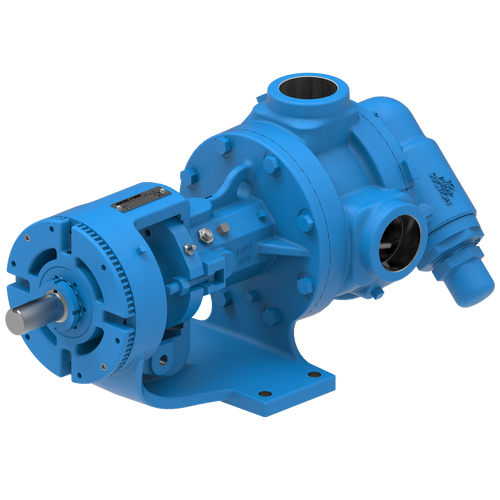

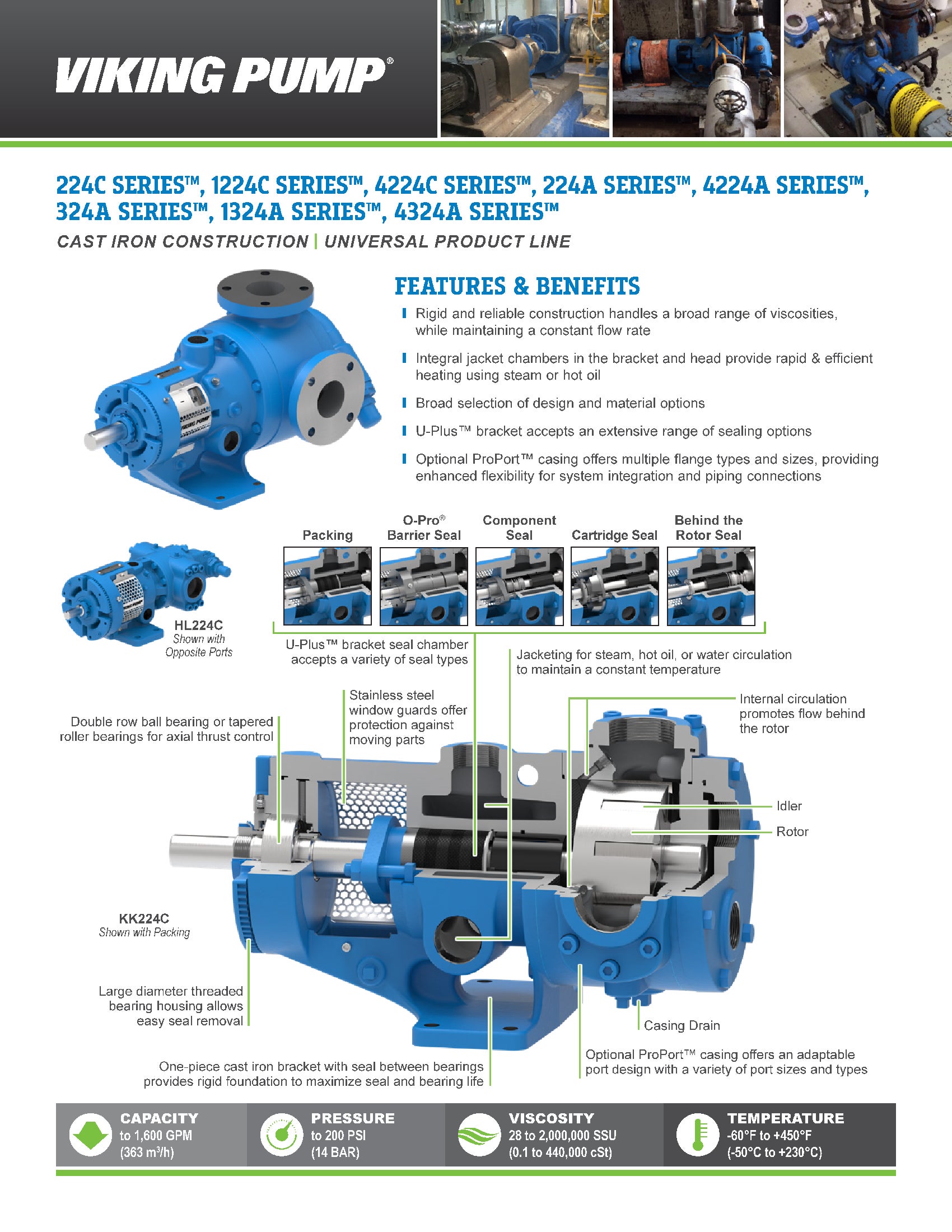

The 224C Series™ internal gear pump is part of Viking Pump's Universal Product Line, delivering unmatched flexibility for demanding fluid handling applications. Featuring the innovative U-Plus™ bracket design, these pumps come standard with packing while also offering the adaptability to meet your ideal configuration.

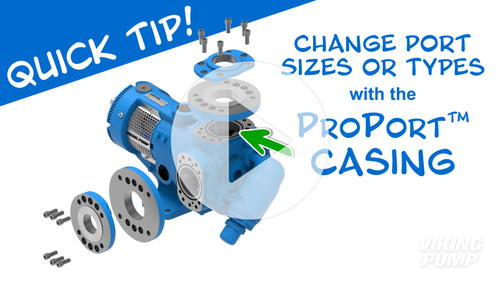

Engineered for performance, the 224C Series™ comes standard with a jacketed head and bracket for superior thermal control and process versatility. Fully compatible with ProPort™ casings, these pumps provide multiple flange types, sizes, and port arrangements for seamless system integration. Ideal for applications such as chemical processing, lubrication systems, fuel transfer, and more, the 224C Series™ ensures reliable operation across diverse conditions.

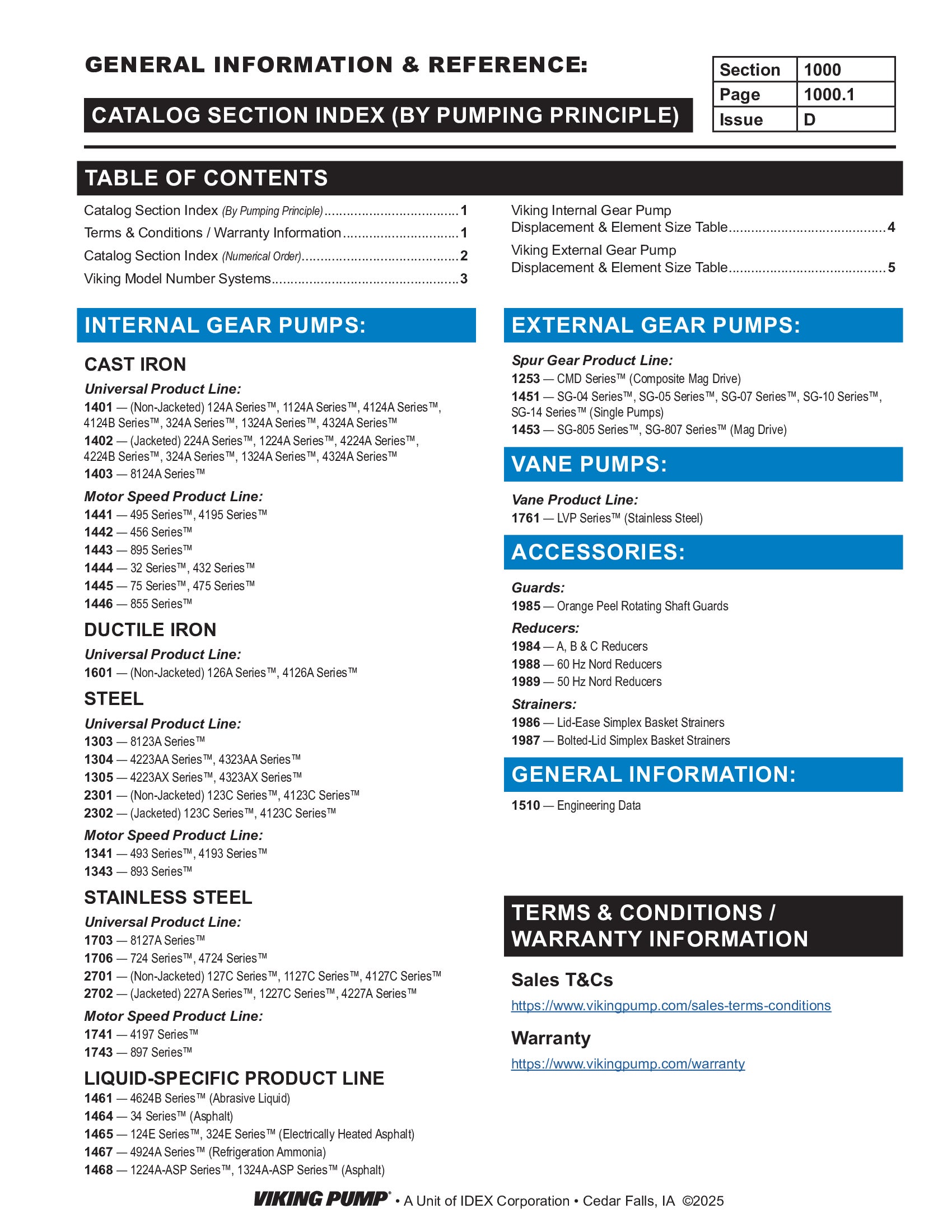

Features & Benefits

- Seal options include packing, O-Pro® Barrier seal, single component seals, cartridge lip seals, and cartridge single and double mechanical seals thanks to the U-Plus™ Bracket which comes standard

- Jacketed pumps provide a cavity, or jacket, on the external wall of the pump through which steam or heat transfer liquid can be passed to control the temperature of the fluid in the pump.

- Viking Pump's most adaptable line of internal gear pumps provide numerous design and material options to meet diverse application needs.

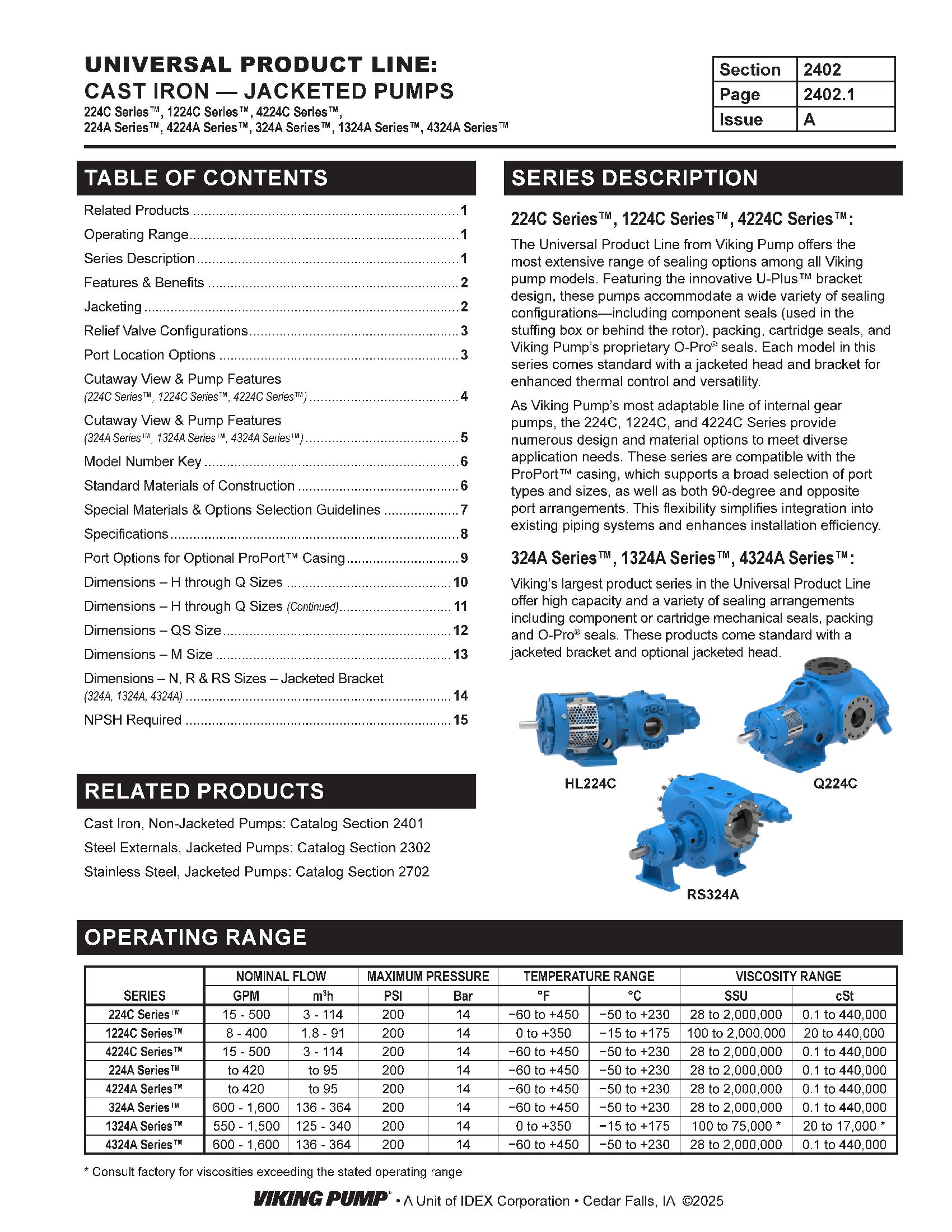

Capacity

15 to 500 GPM

3 to 114 m³/h

Viscosity

28 to 2,000,000 SSU

0.1 to 440,000 cSt

Pressure

200 PSI

14 BAR

Temperature

-60 to +450 °F

-50 to +230 °C

Options

Porting

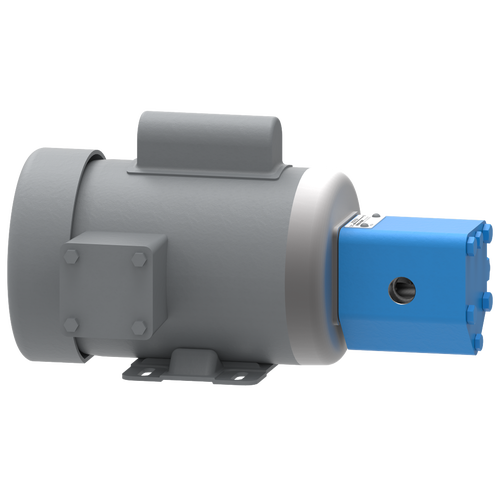

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating GPM | Nominal Pump Rating m3/h | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H224C | 1.5 inches | 15 GPM | 3.5 m3/h | 1750 RPM | 200 PSI | 14 BAR |

| HL224C | 1.5 inches | 30 GPM | 7 m3/h | 1750 RPM | 200 PSI | 14 BAR |

| K224C | 2 inches | 80 GPM | 18 m3/h | 780 RPM | 200 PSI | 14 BAR |

| KK224C | 2 inches | 100 GPM | 23 m3/h | 780 RPM | 200 PSI | 14 BAR |

| L224C | 2 inches | 135 GPM | 31 m3/h | 640 RPM | 200 PSI | 14 BAR |

| LL224C | 3 inches | 140 GPM | 32 m3/h | 520 RPM | 200 PSI | 14 BAR |

| LS224C | 3 inches | 200 GPM | 45 m3/h | 640 RPM | 200 PSI | 14 BAR |

| Q224C | 4 inches | 300 GPM | 68 m3/h | 520 RPM | 200 PSI | 14 BAR |

| QS224C | 6 inches | 500 GPM | 114 m3/h | 520 RPM | 200 PSI | 14 BAR |

Videos

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

Asphalt Emulsions

Emulsions are asphalt suspended in a mixture with water or other liquids. This is done to ease the application of the asphalt. Uses would be crack filling, coating roadways, or waterproofing. These emulsions are shear sensitive and must be handled with care.

High Fructose Corn Syrup (HFCS)

High Fructose Corn Syrup (HFCS) is usually followed by the percentage of fructose in the liquid, ranging from 42 to 55%. It is most commonly used in soft drinks, jams, and jellies as a sweetener. Temperature regulation is relevant because discoloration of the liquid could occur at elevated temperatures.

Hot Melt

Hot Melt adhesives are thermoplastic polymers that soften (become less viscous) when heated. Applied by a local system that melts the adhesive and adjusts pump speed to match the speed of the converting machine.

Liquid Fats

Recycled animal fats and vegetable oils are used in the production of animal feeds for many reasons including the acceleration of growth rates, improved taste, providing essential fatty acids and to act as a binder for producing feed pellets. Typical products include oils derived from corn, soybeans, peanuts as well as animal fats.

-

DRAWINGS

H-HL with Jacketed Head - 1.5" NPT RH/LH PDF

STEP

H-HL with Jacketed Head and ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with Jacketed Head and ProPort Casing - 2" Class 150 ANSI RH/LH PDF

STEP

H-HL with Jacketed Head and ProPort Casing - 2" Class 300 ANSI RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with RV and ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

H-HL with RV and ProPort Casing - 2" Class 150 ANSI RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 2" Class 300 ANSI RH/LH PDF

STEP

K-KK with Jacketed Head - 2" NPT RH/LH PDF

STEP

K-KK with Jacketed Head - 4" Class 125 ANSI RH/LH PDF

K-KK with Jacketed Head and ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with Jacketed Head and ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

K-KK with Relief Valve - 2" NPT RH/LH PDF

STEP

K-KK with Relief Valve - 4" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" NPT RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with Jacketed Head - 2" NPT RH/LH PDF

L with Jacketed Head and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with Jacketed Head and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

L with Jacketed Head and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with Jacketed Relief Valve - 2" NPT RH/LH PDF

L with Jacketed RV and ProPort Casing - 2" NPT RH/LH PDF

L with Jacketed RV and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with Jacketed RV and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

L with Jacketed RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with Jacketed RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

L with Jacketed RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

L with Jacketed RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

L with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with Relief Valve - 2" NPT RH/LH PDF

STEP

L with RV and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LL with Jacketed Head - 3" Class 125 ANSI RH/LH PDF

LL with Jacketed Head and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with Jacketed Head and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with Jacketed Relief Valve - 3" Class 125 ANSI RH/LH PDF

LL with Jacketed Relief Valve - 3" Class 125 ANSI RH/LH PDF

LL with Jacketed RV and ProPort Casing - 3" Class PDF

LL with Jacketed RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with Jacketed RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

LL with Jacketed RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

LL with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LL with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Jacketed Head and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with Jacketed Head - 3" Class 125 ANSI RH/LH PDF

LS with Jacketed Head and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LS with Jacketed Head and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

STEP

LS with Jacketed Relief Valve - 3" Class 125 ANSI RH/LH PDF

LS with Jacketed RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with Jacketed RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LS with Jacketed RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

LS with Jacketed RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

LS with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

STEP

Q with Jacketed Head - 4" Class 125 ANSI RH/LH PDF

STEP

Q with Jacketed Head and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with Jacketed Head and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q with Jacketed Relief Valve - 4" Class 125 ANSI RH/LH PDF

Q with Jacketed Relief Valve - 6" Class 125 ANSI Opposite PDF

Q with Jacketed RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with Jacketed RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q with Jacketed RV and ProPort Casing - 6" Class 125 ANSI Opposite PDF

Q with Jacketed RV and ProPort Casing - 6" Class 250 ANSI Opposite PDF

Q with Relief Valve - 4" Class 125 ANSI RH/LH PDF

STEP

Q with RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

QS with Jacketed Head - 6" Class 125 ANSI Opposite PDF

STEP

QS with Jacketed Head and ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with Jacketed Head and ProPort Casing - 6" Class 250 ANSI Opposite PDF

QS with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

QS with RV and ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with RV and ProPort Casing - 6" Class 250 ANSI Opposite PDF