Asphalt Emulsions

Asphalt Emulsions

Custom Content One

Positive displacement pumps are ideal for transferring asphalt emulsions due to their ability to handle high-viscosity fluids with precision and reliability. Unlike centrifugal pumps, which rely on high-speed rotation, positive displacement pumps move fluid by trapping a fixed amount in a chamber and then forcing it into the discharge pipe, ensuring a consistent flow regardless of pressure changes. This capability is essential for managing the thick, sticky nature of asphalt emulsions, which can pose challenges in maintaining a steady flow without degradation to the liquid mixture. Additionally, these pumps provide excellent control over flow rates and can handle the temperature-sensitive properties of asphalt emulsions effectively, minimizing the risk of solidification or separation during transfer. This makes positive displacement pumps the preferred choice for industries dealing with asphalt-related applications, ensuring operational efficiency and product integrity.

Recommended Pumps

-

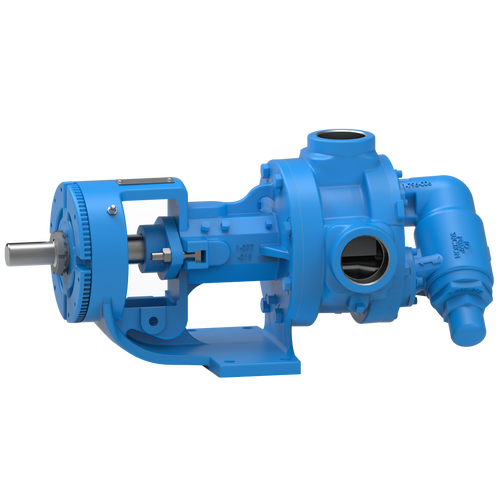

4224A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

Articles / Case Studies

The terms bitumen and asphalt are often used interchangeably, but they are two completely different materials, causing confusion inside and outside the industry. Throw in regional differences in meaning and language, and it’s time to set the record straight, along with tips on bitumen pump selection.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025