Agave Syrup

Agave syrup, a high fructose natural sweetener 1.4 times sweeter than sugar, is derived from the heart, or piña, of any of several agave species. It is processed and sold in stores as a liquid sweetener and has several applications in food and beverage processing, especially in vegan foods as well as mezcal and tequila production. For syrup production, the hearts are milled to a pulp and then the liquid is separated by crushing or centrifugation. It may be further processed through filtration, activated charcoal, ionic resins or enzymes.

Positive displacement pumps are ideal for transferring agave syrup due to their ability to handle highly viscous and shear-sensitive fluids effectively. Agave syrup, being thick and sticky, requires a pumping mechanism that can maintain a consistent flow without degrading or altering the product's quality. Additionally, they offer the capability to handle varying viscosities and are capable of operating at slower speeds, reducing the risk of cavitation and ensuring the syrup's natural consistency and flavor are preserved during the transfer process. These features make positive displacement pumps a reliable and efficient choice for manufacturers dealing with agave syrup. Because sugars may be susceptible to microbial contamination, hygienic pump designs allowing clean-in-place or strip clean are generally preferred.

Applications

- Process Transfer

- Bottling

- Metering

Viking in the Process

Viking pumps are used in syrup processing to transfer raw agave syrup from the crusher or centrifuge to further processing and then to bottling machines, or to fermentation tanks for alcohol production. They are also used in downstream food processing plants to transfer or meter syrup into other products.

Recommended Pumps

-

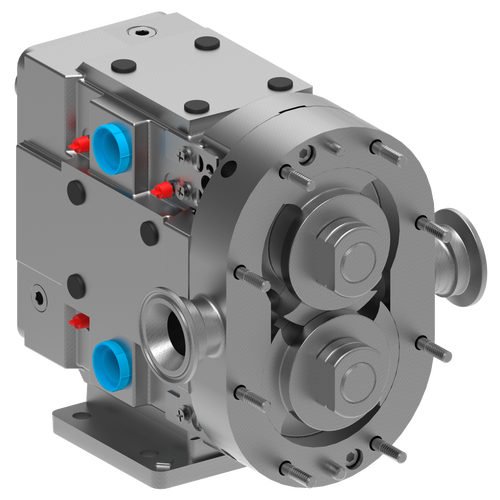

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- 0-450 gpm | 0-102 m3h

-

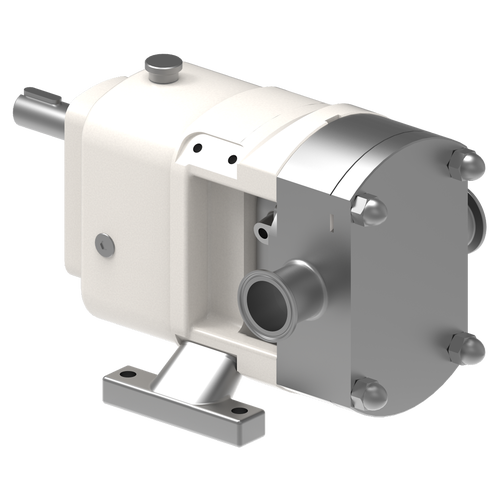

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- 0-832 gpm | 0-189 m3h

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025