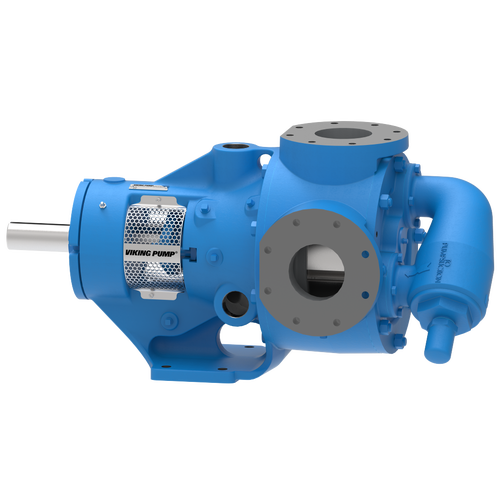

The Next Generation Delivers Real Flexibility

Viking Pump's innovative U-Plus™ Bracket means seal changes are now easier than ever- and switching seal types no longer requires major pump modification.

The U-Plus™ Bracket is a universal seal chamber designed to accept virtually any sealing configuration—packing, stuffing box component mechanical seals, cartridge seals, behind-the-rotor mechanical seals, or Viking's O-Pro® seals—without requiring pump modifications.

If a seal isn't meeting your expectations for leakage prevention or service life, you can switch to a different type on the same bracket. Every pump with a U-Plus™ Bracket also includes standard perforated window guards that meet OSHA and 2006/42/EC Machinery Directive requirements, keeping your team protected without adding maintenance steps.

Ultra Adaptable ProPort™ Casing

Viking Pump's ProPort™ Casing features a bolt-on port design that adapts to your facility's existing piping—not the other way around. Instead of reworking infrastructure to fit a pump, you select from a range of port sizes and types including NPT, ANSI, and DIN options.

Available in both 90° and opposite port configurations, the ProPort™ Casing gives you the layout flexibility to work within your plant's footprint. Every casing also comes standard with a drain port for safer, cleaner maintenance and O-ring grooves machined in—features that previously added cost and lead time are now built in from the start.

The ProPort™ Casing comes standard with stainless steel and steel Viking pumps and are an optional upgrade for cast iron Viking pumps.

Once you own your next generation Viking pump, keeping up with maintenance or changes within the facility are no problem. Keep the core pump the same while having replacement flange faces, ports, seals, and casings so that the pump can evolve with you.

Heading

CHANGE THE PORT, NOT THE PUMP

Re-piping doesn’t mean you have to purchase a brand new pump and take the time to install it. Simply take a look at the replacement ports you have on the shelf or check with your area distributor.

Heading

CHANGE THE SEAL, NOT THE PUMP

If you determine that going from a behind the rotor seal to a cartridge seal is the way to go, simply reach for a spare cartridge seal on your shelf and replace it.

Heading

CHANGE THE CASING, NOT THE PUMP

Are you looking at an efficient piping change that means a 180° casing no longer fits best with the setup? Reduce the work it would take to install a brand new 90° oriented pump and swap out the casing instead.

This is just a small-scale example of what ONE pump can do. When you use Viking Pump’s new generation of adaptable pumps, keeping spare ports, flange faces, and seals in your inventory means being able to do maintenance and updates across ALL of the Viking pumps at your facility.

VIEW PUMPS

GET A QUOTE

Expanded Seal Flexibility with U-Plus™ Brackets

Viking Pump’s new generation of pumps (sizes H-QS in steel and stainless steel) offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of sealing flexibility. These new pumps increase the number of sealing options possible in one pump, while at the same time reducing cost and lead times.

All You Need to Know About ProPort™ Casings

Viking Pump’s new generation of internal gear pumps offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of porting flexibility. These new pumps reduced the number of casing configurations, which helps reduce manufacturing complexity, cost and lead times, while at the same time increasing the number of porting options and providing greater porting flexibility.

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. We have dedicated sales and field support specialists who are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers available to help with product selection and technical support. USA based company with vertically integrated manufacturing facility.

ALL PUMPS FACTORY TESTED

Our state-of-the-art testing equipment is used to confirm performance prior to shipments. Our world-class lab gives Viking Pump the ability to test our pump designs across a range of relevant variables.

TEST LAB

Our world-class lab gives Viking the ability to test its glycol pump designs across a range of relevant variables.

VERTICALLY INTEGRATED PRODUCTION PROCESS

Viking Pump operates a foundry, a 200,000+ sq. ft. machining, assembly and testing center, and an extensive product engineering and testing lab in its world headquarters in Cedar Falls, Iowa, USA. This level of vertical integration ensures maximum quality, ability to satisfy special needs, and to meet project schedules.