Massecuite

Massecuite

Custom Content One

Massecuite is a mixture of raw sugar crystals and liquor made by seeding supersaturated cane or beet juice prior to crystallization and the removal of the molasses by centrifuging. It contains a high concentration of abrasive sugar crystals.

Massecuites are sugar liquids created at intermediate stages of both cane and beet sugar manufacturing processes. Juice liquor is concentrated in a series of vacuum evaporator pans where seed magma “footing” is added to help sugar crystals form. The massecuite is pumped through the series of pans, then to a crystallizer, then to the centrifugals where the molasses is removed, and sugar crystals are discharged to a sugar dryer.

Massecuite is a particularly difficult liquid to pump due its high viscosity (up to 500,000 cPs), high temperature (80 to 90ᵒC, or 175 to 195ᵒF), high specific gravity (about 1.47), the extreme sensitivity of its seed crystals to crushing though shear forces, and its abrasiveness. Slow operating rotary positive displacement pumps are critical to ensuring the sensitive crystals are not damaged, which would reduce the yield. They do this by creating large cavities which fill with massecuite at the pump suction and then displacing it at the pump discharge, creating flow to the next pan or next step in the process.

Custom Content One

Viking in the Process

Viking pumps are used in both cane and beet plants to transfer syrup and then massecuite through the process from pan to pan to crystallizer and mingler, to meter seed magma back to the pans, and to transfer molasses from the centrifugals to storage and railcar loading or packaging. Through much experience working with sugar producers, Viking pump has learned the maximum operating speeds which will prevent massecuite crystal damage while optimizing flow rate, using hard materials to minimize abrasion, and unique shaft sealing solutions to prevent leakage common to simple packed pumps.

Custom Content Two

Applications

- Syrup Transfer

- A, B & C (Low Green, Intermediate Green, High Green) Massecuite Vacuum Pan Discharge

- Massecuite Mingler Discharge

- Magma transfer

- A, B & C Molasses Transfer, Railcar Loading

Recommended Pumps

-

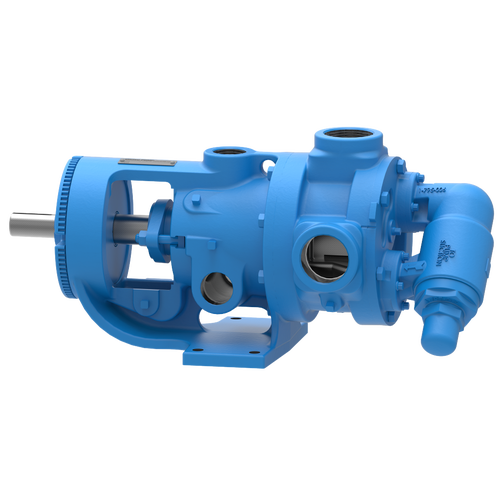

224A SERIES™

- Cast Iron

- Packing

- up to 500 gpm | up to 114 m3h

-

227C Series™

- Stainless Steel

- Packing

- up to 320 gpm | up to 73 m3h

-

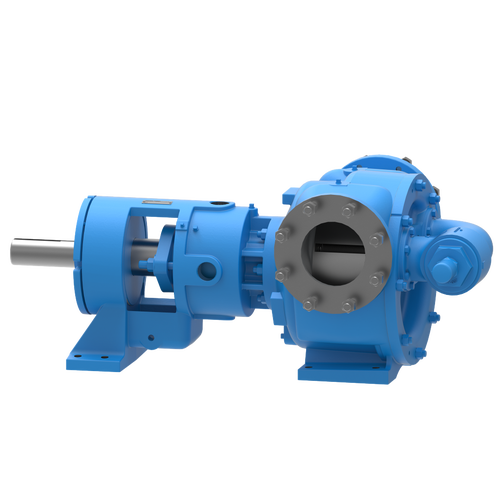

324A Series™

- Cast Iron

- Packing

- 500-1600 gpm | 114-364 m3h

Articles / Case Studies

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025

50 States / 50 Pumping Applications: Nebraska, Arizona, Virginia, Louisiana, MichiganSince our founding in 1911, Viking Pump has built over 7,000,000 pumps and supplied them to customers all over the world. These pumps handle the broadest range of liquids in the industry. We’ve prepared a listing of 50 Viking pump applications, tying each to a state where this application can commonly be found. Today let’s explore Viking Pump applications in Nebraska, Arizona, Virginia, Louisiana, and Michigan.March 14, 2025