Glucose

Glucose

Custom Content One

Glucose is a simple sugar produced by plants and is an abundant source of carbohydrate. It is processed into glucose syrup and used as a sweetener in foods and confectionery products.

Glucose is produced from starch via enzymatic hydrolysis using glucose amylase as the enzyme. It begins with starch milk, which is hydrolyzed through a saccharification process, then filtered, demineralized, de-colored and concentrated prior to storage and packaging for transport. It is used in food processing as a sweetener and as a humectant to keep moisture in food. Glucose syrup is used in confectioneries such as candies, toffee, and fondant. It has relatively low viscosity compared to other sugar syrups, with a 40% solution only 5.4 cPs at 20ᵒC (68ᵒF), but has high density, with a specific gravity of 1.5.

Hygienic positive displacement pumps are essential for manufacturing and handling glucose due to their very low Net Positive Suction Head required (NPSHr), which helps prevent cavitation on high specific gravity fluids like glucose syrup. These pumps are designed with smooth, polished surfaces and are easy to clean, which minimizes the risk of contamination and ensures compliance with stringent sanitary standards. Their gentle pumping action prevents shearing and degradation of the glucose, preserving its quality and consistency throughout the production process. Additionally, positive displacement pumps offer precise flow control, making them ideal for the continuous and accurate movement of glucose in manufacturing environments. Their reliability and efficiency contribute to optimized production processes, reducing downtime and ensuring a higher yield of high-quality glucose product.

Custom Content One

Viking in the Process

Viking pumps are used in glucose manufacturing, from transfer of starch milk to saccharification, to glucose transfer through the final processing, storage and packaging or transport stages. Viking pumps are also used to transfer and meter glucose syrup in downstream food, baking, beverage and confectionery facilities.

Custom Content Two

Applications

- Starch milk transfer

- Glucose transfer and metering

Recommended Pumps

-

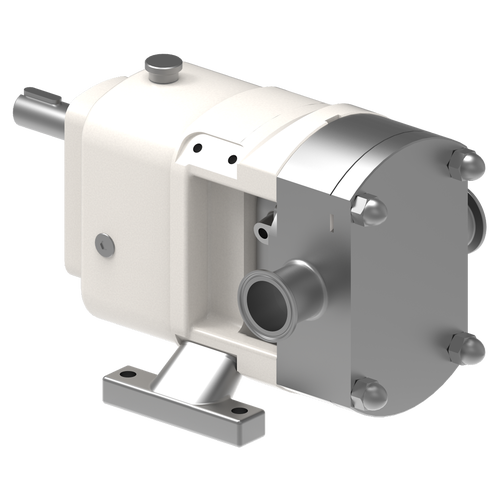

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

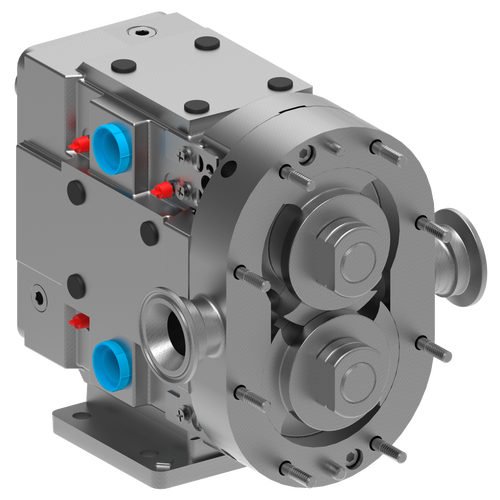

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

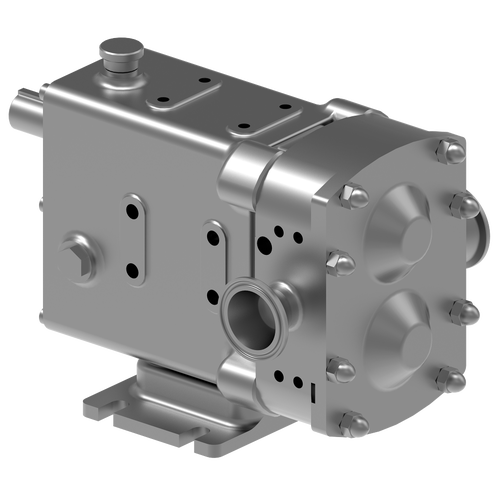

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025