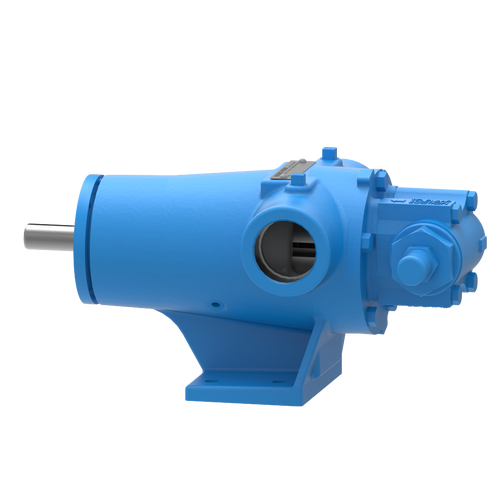

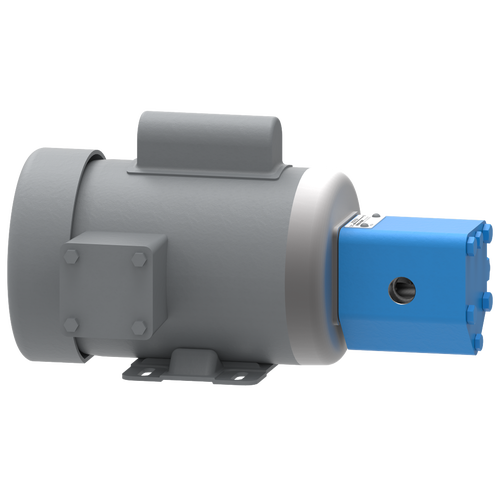

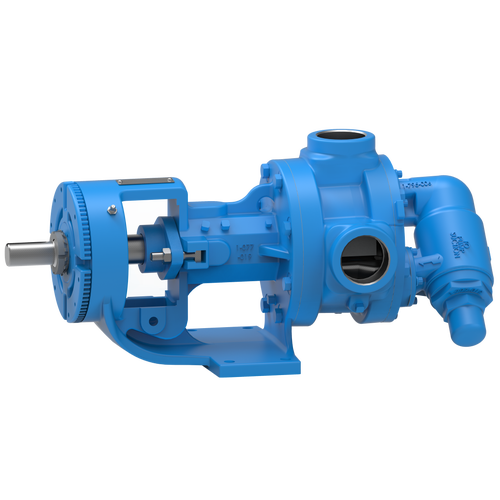

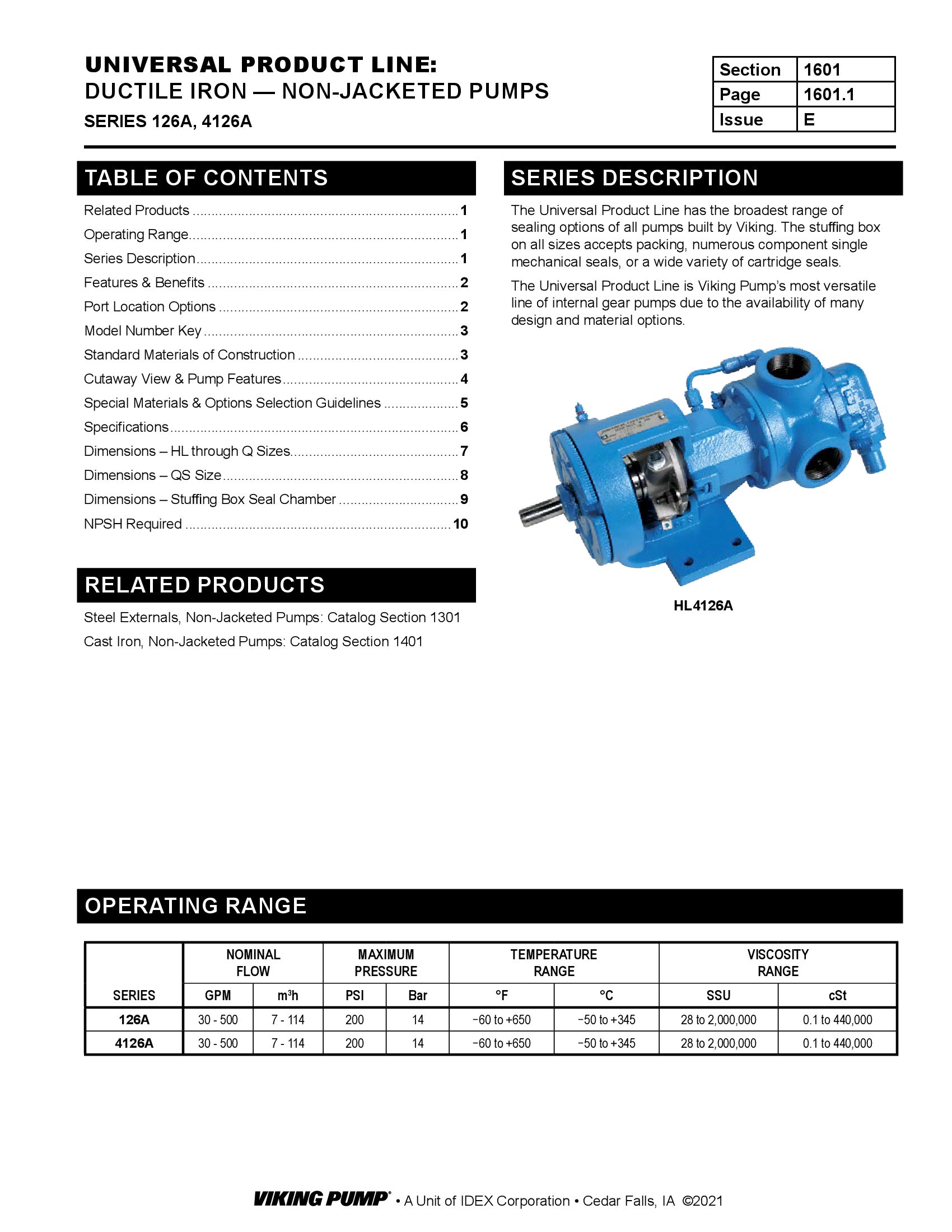

The 4126A Series™ internal gear pump is the most versatile line of internal gear pumps due to the availability of many design and other options. It can handle a broad range of viscosities with constant flow rate up to 500 GPM (114 m³/h).

Features & Benefits

- Positive displacement internal gear pumping principle handles a broad range of viscosities with constant flow rate

- Axial rotor thrust is controlled by double row ball bearing or tapered roller bearings; a bushing provides a secondary point of radial shaft support

- Rotatable bearing housing provides easy rotor end clearance adjustment for viscosity or to compensate wear

Capacity

to 500 GPM

to 114 m³/h

Viscosity

28 to 2,000,000 SSU

1 to 440,000 cSt

Pressure

to 200 PSI

to 14 Bar

Temperature

-60 to +650 °F

-50 to +345 °C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating (m3/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H4126A | 1.5 | 15 | 2.8 | 1750 | 200 | 14 |

| HL4126A | 1.5 | 30 | 5.6 | 1750 | 200 | 14 |

| K4126A | 2 | 80 | 18 | 780 | 200 | 14 |

| KK4126A | 2 | 100 | 23 | 780 | 200 | 14 |

| L4126A | 2 | 135 | 31 | 640 | 200 | 14 |

| LQ4126A | 2.5 | 135 | 31 | 640 | 200 | 14 |

| LL4126A | 3 | 140 | 32 | 520 | 200 | 14 |

| LS4126A | 3 | 200 | 45 | 640 | 200 | 14 |

| Q4126A | 4 | 300 | 68 | 520 | 200 | 14 |

| QS4126A | 6 | 500 | 114 | 520 | 200 | 14 |

Videos

Refined Fuels

Refined fuels would include petroleum based fuel oils and some Jet Fuels. Their viscosity and temperature handled can vary greatly. Normally these are handled in bulk transfer operations.

Biofuels

Biofuels include Biodiesel and Ethanol. These are fuels made from renewable resources and typically blended with refined fuels as additives.

Glycol (Ethylene Glycol, Ethylene Alcohol)

A clear, colorless, syrupy liquid used in a variety of applications involving lacquers, resins, printing inks, adhesives, waxes, and pharmaceuticals. It is often blended with water and used as a coolant and anti-freezing agent.

-

REPAIR RESOURCES

-

DRAWINGS

H-HL with Plain Head - 1.5" NPT RH/LH PDF

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

H-HL with RV and ProPort Casing - DIN 40 PN16 Opposite PDF

K-KK with Plain Head - 2" Class 150 RH/LH PDF

K-KK with Plain Head - 2" NPT RH/LH PDF

K-KK with Relief Valve - 2" Class 150 RH/LH PDF

K-KK with Relief Valve - 2" NPT RH/LH PDF

L with Plain Head - 2" NPT RH PDF

L with Relief Valve - 2" NPT RH PDF

LL with Plain Head - 3" Class 125 ANSI RH/LH PDF

LL with Relief Valve - 3" Class 125 ANSI RH PDF

LQ with Plain Head - 2.5" Class 125 ANSI RH/LH PDF

LQ with Relief Valve - 2.5" Class 125 ANSI RH/LH PDF

LS with Plain Head - 3" Class 125 ANSI RH/LH PDF

LS with Relief Valve - 3" Class 125 ANSI RH PDF

Q with Relief Valve - 4" Class 150 ANSI RH/LH with Studs and Bolts PDF

QS with Plain Head - 4" Class 125 ANSI RH/LH PDF

QS with Plain Head - 6" Class 125 ANSI Opposite PDF

QS with Relief Valve - 6" Class 150 ANSI Opposite PDF

QS with Relief Valve - 6" Class 150 ANSI RH PDF