Glycol (Ethylene Glycol, Ethylene Alcohol)

Glycol (Ethylene Glycol, Ethylene Alcohol)

Custom Content One

Glycols are alcohols with unique properties, such as a high boiling point and good water solubility, that makes them attractive in many industries. Common examples include ethylene glycol, propylene glycol and polyethylene glycol.

Ethylene glycol, used in automotive antifreeze, lowers the freezing point and raises the boiling point of water to prevent engines from freezing or overheating. Propylene glycol is similar but is “generally recognized as safe” (GRAS) for use in food, pharmaceuticals, and cosmetics. Glycols are also used as precursors to other chemicals, including polyester resins. Glycols are moderately viscous, with 100% ethylene glycol ranging from about 7 cPs at 120ᵒF (49ᵒC) to 310 cPs at 0ᵒF (-18ᵒC), Propylene glycol is about 3-4 times as viscous.

Positive displacement pumps are ideal for transferring glycols and glycol solutions due to their ability to handle a wide range of viscosities and maintain a consistent flow rate, regardless of system pressure. These pumps work by trapping a fixed amount of fluid and displacing it through the pump's discharge, making them highly effective for handling liquids like glycols that may exhibit varying flow characteristics under different temperature conditions. Additionally, positive displacement pumps offer superior control over flow rates, which ensures precise handling and accurate metering of these substances within industrial processes.

Custom Content One

Viking in the Process

Ethylene glycol and polyethylene glycol are produced by reacting ethylene oxide with water. Propylene glycol is mainly produced from propylene oxide for food-grade use or from glycerol for industrial use. Viking pumps are used in the production processes and to transfer product to storage and packaging or transport. They are also used in downstream processes such as glycol blending for antifreeze or metering into recipes for food, pharma and cosmetic products.

Custom Content Two

Applications

- Glycol transfer

- blending and metering

Recommended Pumps

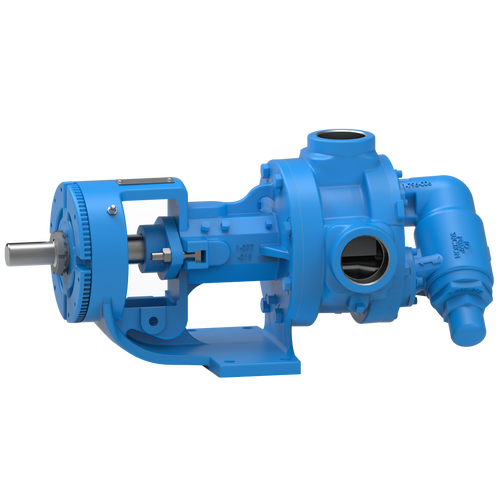

-

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

Articles / Case Studies

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

A new EPA rule (Dec 2, 2023) mandates zero-emissions pumps for oil & gas ops, replacing natural gas-driven pumps. It also limits other gas-powered equipment, curbs fugitive emissions, and reduces flaring of associated gas—with few exceptions.

Videos

895, 893, & 897 Series™ MagDrive Internal Gear Pump RepairIn this video we will guide you through the disassembly and reassembly of Viking Pump’s 893, 895, and 897 Series™ mag drive internal gear pumps.April 11, 2025

895, 893, & 897 Series™ MagDrive Internal Gear Pump RepairIn this video we will guide you through the disassembly and reassembly of Viking Pump’s 893, 895, and 897 Series™ mag drive internal gear pumps.April 11, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025