Honey

Honey

Custom Content One

Honey is a sweet, sticky fluid produced by bees and other insects from nectar collected from flowers. It is used for human food consumption as a sweetener and in some alcoholic products such as mead.

The typical pH of honey is 3.9, which helps to inhibit microbial growth. The melting point of crystallized honey ranges between 40° and 50°C (104° to 122°F). Specific gravity is around 1.4, and viscosity ranges from about 1,300 cPs at 40°C (104°F) to 14,000 cPs at 20°C (68°F).

Positive displacement pumps are ideal for pumping honey due to their ability to handle viscous fluids with precision and care. Unlike centrifugal pumps, which rely on high-speed impellers that can disrupt and degrade viscous fluids, positive displacement pumps use gears, lobed rotors or circumferential pistons to move liquid at a consistent, controlled rate. This ensures that the honey's natural properties, texture, and quality are preserved without aeration or shearing. These pumps provide a constant flow rate regardless of the viscosity changes in the honey, and flow rate is directly proportional to pump speed, allowing for accurate dosing and efficient processing in commercial applications. Their hygienic design allows them to be cleaned in place or strip cleaned as needed, making them the preferred choice for maintaining the integrity of honey during processing.

Custom Content One

Viking in the Process

For raw (unprocessed) honey, Viking pumps are used to transfer honey from the extractor to a strainer to filter out any beeswax or bee parts, and then to packaging.

For commercial honey, Viking pumps are used to transfer raw honey from tank trucks to storage, then through a heat exchanger or heated tank where it is warmed to reduce viscosity, and then through strainers to remove large particles, then through fine filtration, often microfiltration, to remove pollen grains. Then Viking pumps move filtered honey through a pasteurizer to kill yeast cells and dissolve sugar crystals, and finally through a heat exchanger for cooling and on to packaging or bulk transport.

Viking pumps are also used in downstream food processing plants to meter honey into the production process.

Custom Content Two

Applications

- Honey Transport, Processing and Packaging

- Honey Metering in Food Processing Plants

- Viking in the Process

Recommended Pumps

-

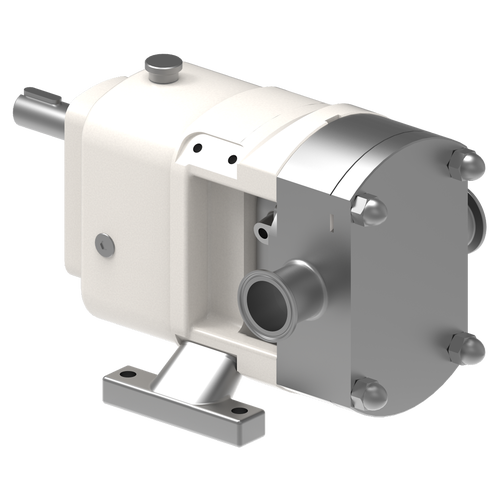

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

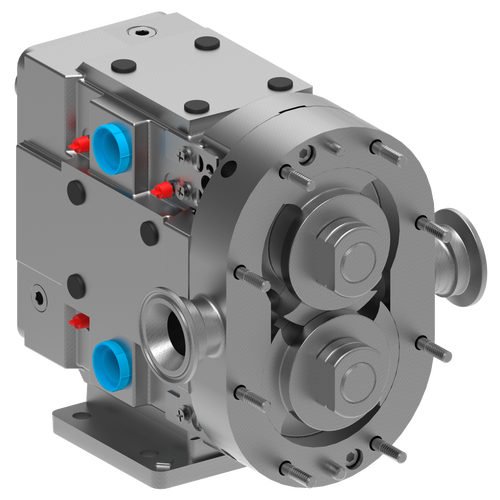

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

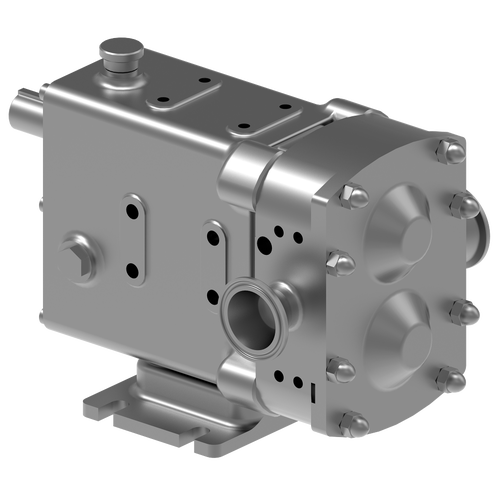

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025