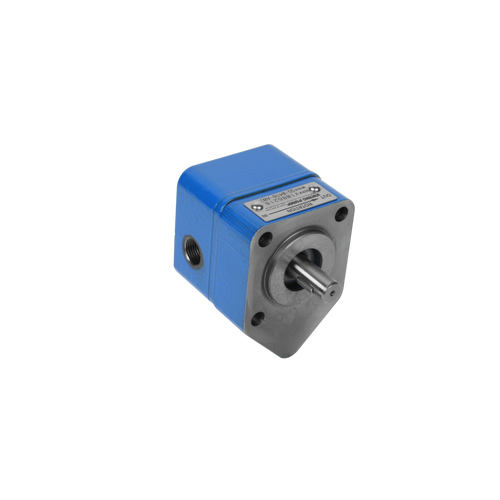

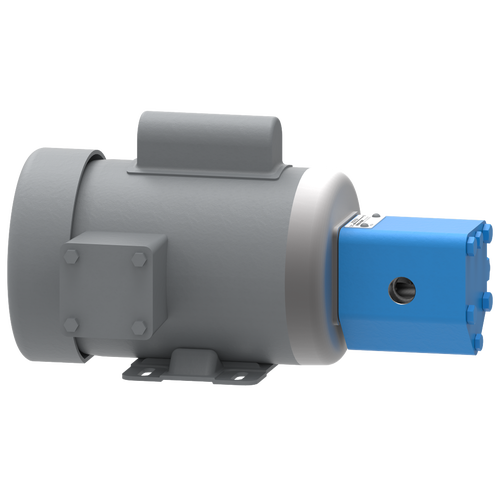

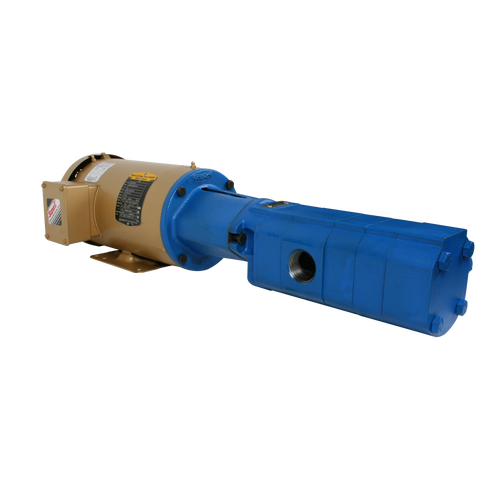

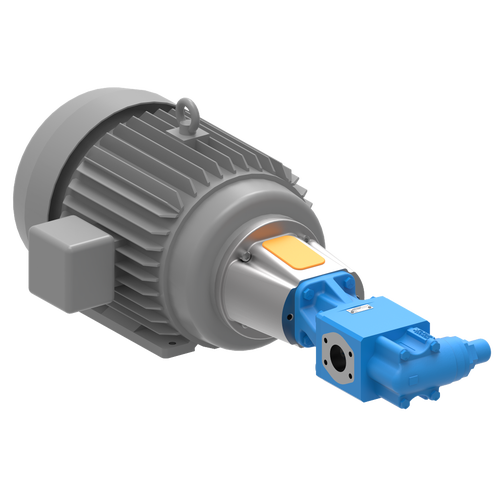

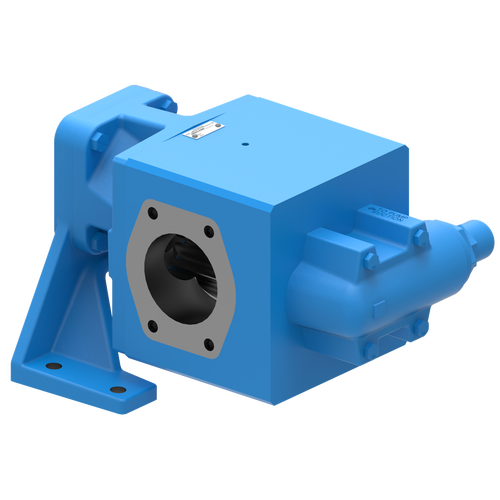

The Viking Pump Spur Gear (SG) Series includes standard external gear pumps and Mag Drive (sealless) variants, designed for high-pressure performance, leak prevention, and versatility. These pumps handle a wide range of liquids and operating conditions, making them ideal for demanding industrial applications.

FEATURES & BENEFITS

- High Pressure Capability - Needle bearings for durability under high pressure; sleeve bearing options for special conditions.

- Flexible Installation - Close-coupled motor mounts or foot brackets for easy integration in tight spaces or speed-reduced setups.

- Cost Efficiency - Double pump configurations allow two flow rates from one power source, reducing equipment costs.

- Long Service Life - Spur-type gears minimize axial thrust; hardened steel gears and shafts reduce wear.

With over 110 years of experience providing positive displacement pumping solutions, Viking Pump has a rich, lengthy history of providing engineered solutions for tough applications. We have dedicated sales and field support specialists who are supported by a team of customer service representatives and engineers. Our knowledgeable team of application engineers available to help with product selection and technical support. USA based company with vertically integrated manufacturing facility.

ALL PUMPS FACTORY TESTED

Our state-of-the-art testing equipment is used to confirm performance prior to shipments. Our world-class lab gives Viking Pump the ability to test our pump designs across a range of relevant variables.

TEST LAB

Our world-class lab gives Viking the ability to test its glycol pump designs across a range of relevant variables.

VERTICALLY INTEGRATED PRODUCTION PROCESS

Viking Pump operates a foundry, a 200,000+ sq. ft. machining, assembly and testing center, and an extensive product engineering and testing lab in its world headquarters in Cedar Falls, Iowa, USA. This level of vertical integration ensures maximum quality, ability to satisfy special needs, and to meet project schedules.