Creams (Medicinal, Cosmetic)

Creams (Medicinal, Cosmetic)

Custom Content One

Positive displacement gear pumps are ideal for manufacturing medicinal creams due to their ability to handle high-viscosity fluids efficiently. They provide a consistent and precise flow rate, which is crucial for maintaining the quality and consistency of the creams. Additionally, these pumps offer gentle handling of shear-sensitive materials, minimizing the risk of altering the product's properties during the pumping process. Their design also facilitates cleaning and sterilization, which are essential in pharmaceutical manufacturing to ensure product safety and compliance with industry standards.

Recommended Pumps

-

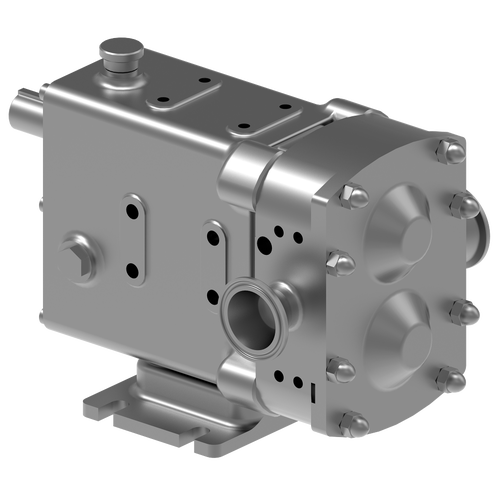

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

-

1127C Series™

- Stainless Steel

- O-Pro® Seal

- up to 320 gpm | up to 73 m3h

-

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

Explore the customizable features of the Revolution® Series Pumps from Viking Pump, designed for efficiency and hygiene in various applications.

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Videos

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025