Chocolate

Chocolate

Custom Content One

Positive displacement gear pumps are ideal for chocolate manufacturing due to their precise flow control, maintaining ingredient ratios and product quality. They handle chocolate gently, minimizing shear and temperature effects, which preserves texture and prevents aeration. These pumps ensure consistent chocolate flow, crucial for processes like molding and enrobing. They handle high-viscosity fluids efficiently, ensuring smooth operations with thick substances. Their durability and reliability make them a dependable choice for the demanding nature of chocolate production, addressing its specialized needs.

Image

Recommended Pumps

-

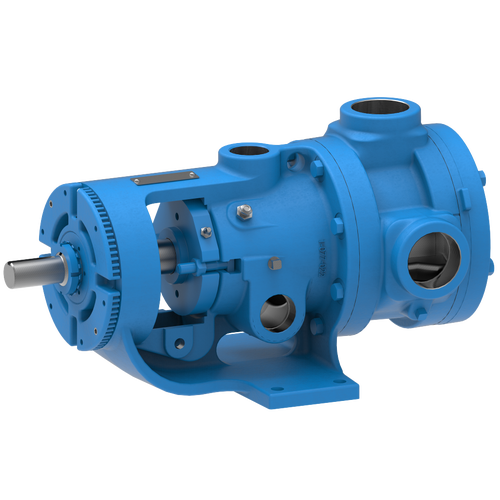

1224A-CHC® SERIES

- Cast Iron

- O-Pro® Seal

- up to 400 gpm | 1.8-91 m3h

-

1227C Series™

- Stainless Steel

- O-Pro® Seal

- up to 320 gpm | up to 73 m3h

Articles / Case Studies

Compare Lobe/CP and Internal Gear Pumps for chocolate and confectionery processing. Learn which pump suits different applications based on hygiene, viscosity, and wear resistance.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025