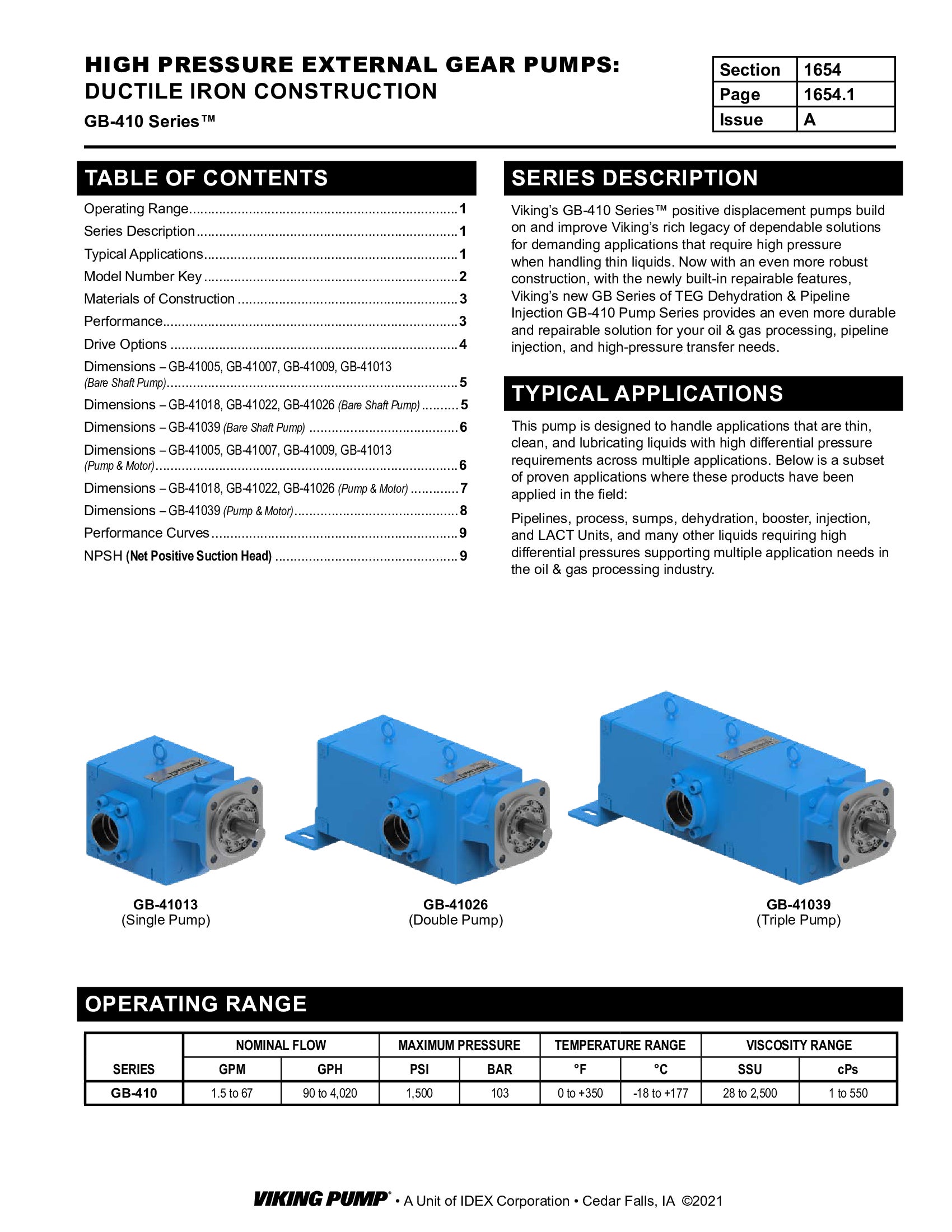

The GB-410 Series™ external gear pump is the ultimate durable, reliable, field-rebuildable solution for your high-pressure oil and gas processing needs. With its hardened parts for enhanced wear resistance, it was engineered specifically for overcoming the challenges of upstream and midstream oil and gas processing applications such as natural gas & CO2 dehydration (glycol), LACT – pipeline injection, gas sweetening (amines), pigging, and condensate transfer.

Features & Benefits

HIGH TEMPERATURE RATING

- All sizes rated to handle temperatures of 350 F to cover upset conditions

- Pumps engineered to handle the high temperature delta between pump & glycol on start-up

- Pumps capable of over 225°F temperature differential between pump and glycol temps

ROBUST DURABLE PUMP DESIGN

- Fewer moving wear components for robust, long-lasting field performance

- New advanced hardened materials on critical internal wear surfaces

- Enhanced wear resistance and durability of dry-run, abrasives, and upset conditions

- Smooth flow with no pulsation dampening equipment required

REBUILDABLE DESIGN

- All wear components are easily replaceable and available in affordable Rebuild Kit

- Simple disassembly & reassembly process for easy field service and repair, saving time and money

RELIABLE MECHANICAL SEAL SOLUTIONS

- Less susceptible to leakage and robust long-lasting design

- Back pull-out seal design allows for easy seal changes in the field

- Axial thrust control standard with single component seal design

EASY FIELD INSTALLATION

- Jaw Type Coupling eliminates the mess and maintenance of an oil bath

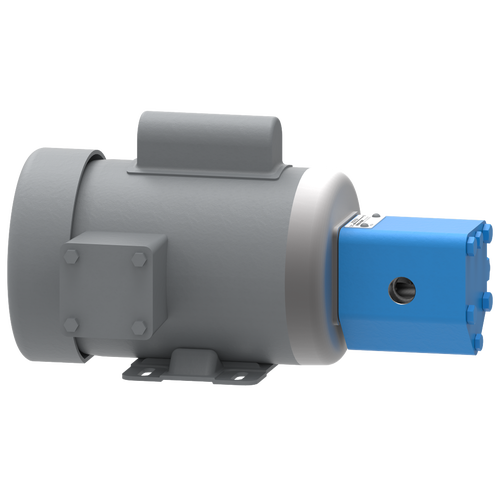

- Motor mounting capable for easy drop-in replacement on C-Face motors up to 75 HP

- Motor speed operation eliminates gear reducers or belt drives

- Standard 180 degree SAE ports with bolt-on NPT or Weld-Neck Adapters to accommodate connection type of your choice

- Pump can be plumbed using hard or flexible piping

ALL PUMPS FACTORY TESTED

- Each pump performance and hydro tested with state-of-the-art testing equipment prior to shipment

Capacity

2 to 67 GPM

Viscosity

>1 to 550 cPs

Pressure

to 1500 PSI

to 103 BAR

Temperature

0 to +350 °F

Options

Porting

Drives

Mounting

Sealing

Specifications

| Pump Model (Ductile Iron Externals) | Port Size & Type (Inches) | Nominal Flow at 1500 PSI, 1765 RPM on 150°F 8 cPs TEG (GPM) | Nominal Flow at 1500 PSI, 1765 RPM on 150°F 8 cPs TEG (GPH) | Nominal Flow at 1500 PSI, 1765 RPM on 250°F 1.2 cPs TEG (GPM) | Nominal Flow at 1500 PSI, 1765 RPM on 250°F 1.2 cPs TEG (GPH) | Max Continuous Pressure PSI | Max Continuous Pressure BAR | Max Recommended Temperature °F | Max Recommended Temperature °C | Approx. Shipping Weight ** (LBs) | Approx. Shipping Weight ** (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| GB-41005 | 2" NPT* | 7.9 | 474 | 7.6 | 456 | 1500 | 103 | 350 | 175 | 70 | 32 |

| GB-41007 | 2" NPT* | 11.2 | 672 | 10.7 | 642 | 1500 | 103 | 350 | 175 | 72 | 33 |

| GB-41009 | 2" NPT* | 13.6 | 816 | 13.1 | 786 | 1500 | 103 | 350 | 175 | 73 | 33 |

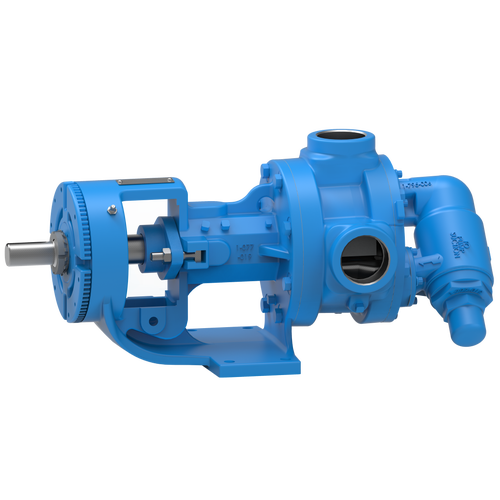

| GB-41013 | 2" NPT* | 21.2 | 1272 | 20.2 | 1212 | 1500 | 103 | 350 | 175 | 77 | 35 |

| GB-41018 | 2" NPT* | 28.1 | 1686 | 26.8 | 1608 | 1500 | 103 | 350 | 175 | 117 | 53 |

| GB-41022 | 2" NPT* | 36.8 | 2208 | 34.6 | 2076 | 1500 | 103 | 350 | 175 | 120 | 54 |

| GB-41026 | 2" NPT* | 44 | 2640 | 40.9 | 2454 | 1500 | 103 | 350 | 175 | 124 | 56 |

| GB-41039 | 2" NPT* | 66.8 | 4008 | 63.7 | 3822 | 1500 | 103 | 350 | 175 | 170 | 77 |

Videos

Refined Fuels

Refined fuels would include petroleum based fuel oils and some Jet Fuels. Their viscosity and temperature handled can vary greatly. Normally these are handled in bulk transfer operations.

Glycol (Ethylene Glycol, Ethylene Alcohol)

A clear, colorless, syrupy liquid used in a variety of applications involving lacquers, resins, printing inks, adhesives, waxes, and pharmaceuticals. It is often blended with water and used as a coolant and anti-freezing agent.

-

REPAIR RESOURCES

Gas Dehydration Pump Rebuild | Triple Pump Gas Dehydration Pump Rebuild | Double Pump Mechanical Seal Replacement | GB-410 Series™ Gas Dehydration Pump Rebuild | Single Pump

-

DRAWINGS

GB41005 - 2" NPT Opposite 182/184TC PDF

STEP

GB41005 - 2" NPT Opposite 213/215TC PDF

STEP

GB41007 - 2" NPT Opposite 213/215TC PDF

STEP

GB41007 - 2" NPT Opposite 254/256TC PDF

STEP

GB41009 - 2" NPT Opposite 254/256TC PDF

STEP

GB41009 - 2" NPT Opposite 284/286TC PDF

STEP

GB41013 - 2" NPT Opposite 254/256TC PDF

STEP

GB41013 - 2" NPT Opposite 284/286TC PDF

STEP

GB41013 - 2" NPT Opposite 324/326TC PDF

STEP

GB41018 - 2" NPT Opposite 254/256TC PDF

STEP

GB41018 - 2" NPT Opposite 284/286TC PDF

STEP

GB41018 - 2" NPT Opposite 324/326TC PDF

STEP

GB41022 - 2" NPT Opposite 284/286TC PDF

STEP

GB41022 - 2" NPT Opposite 324/326TC PDF

STEP

GB41026 - 2" NPT Opposite 284/286TC PDF

STEP

GB41026 - 2" NPT Opposite 324/326TC PDF

STEP

GB41026 - 2" NPT Opposite 364/365TC PDF

STEP

GB41039 - 2" NPT Opposite 324/326TC PDF

STEP

GB41039 - 2" NPT Opposite 364/365TC PDF

STEP