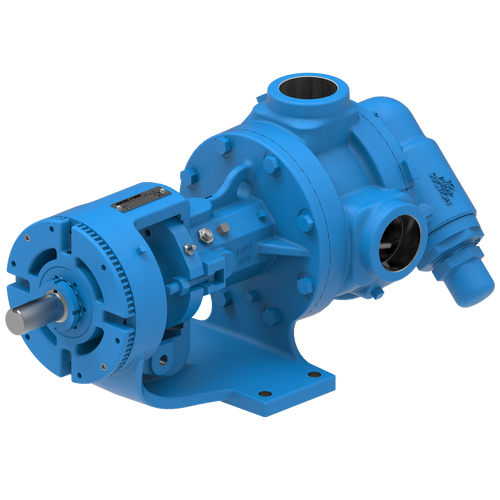

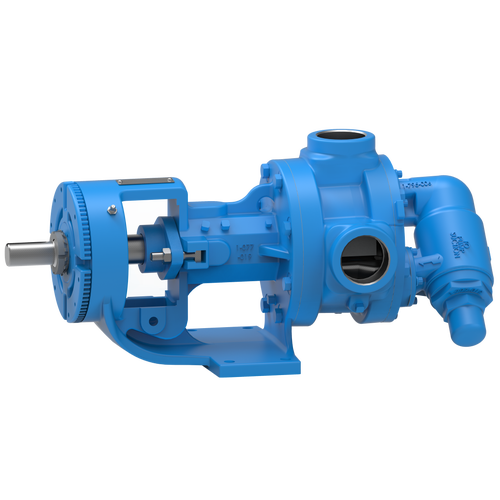

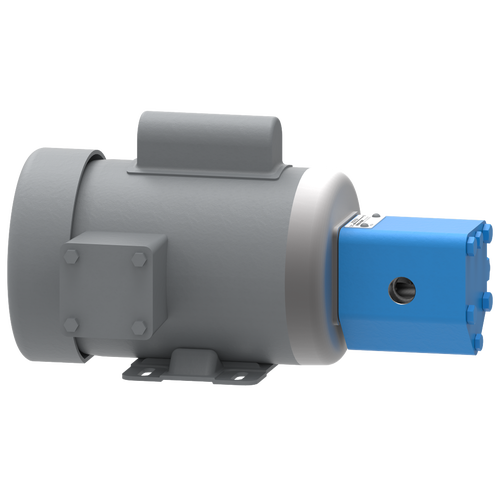

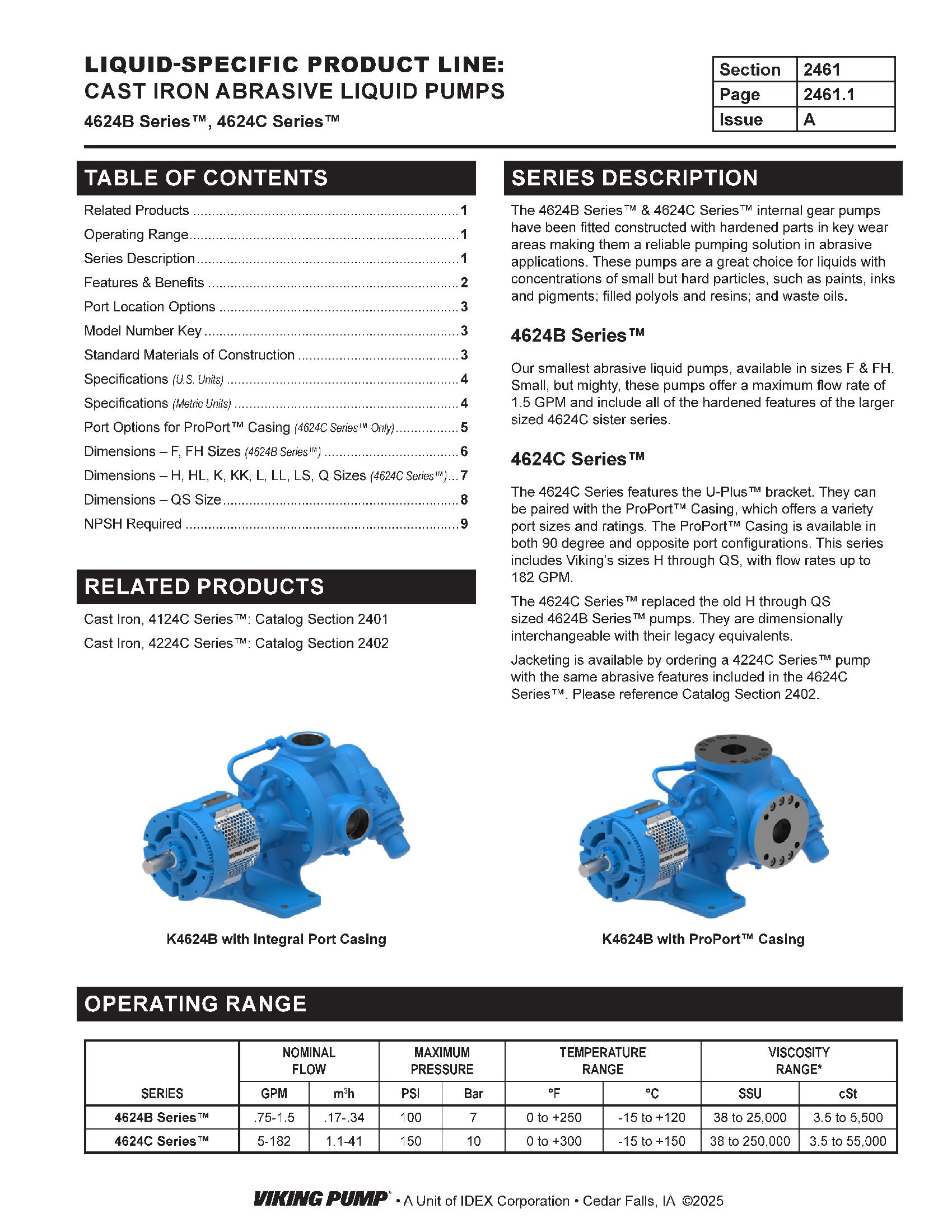

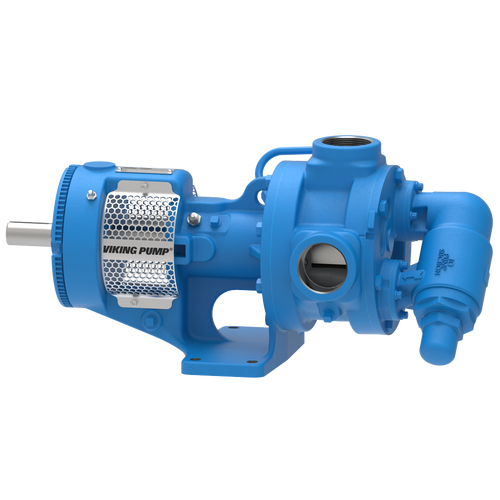

The 4624C Series™ internal gear pump has been constructed with hardened parts in key wear areas making it a reliable pumping solution in abrasive applications. This pump is a great choice for liquids with concentrations of small but hard particles, such as paints, inks and pigments; filled polyols and resins; and waste oils. It can handle flows up to 182 GPM (41 m³/h.

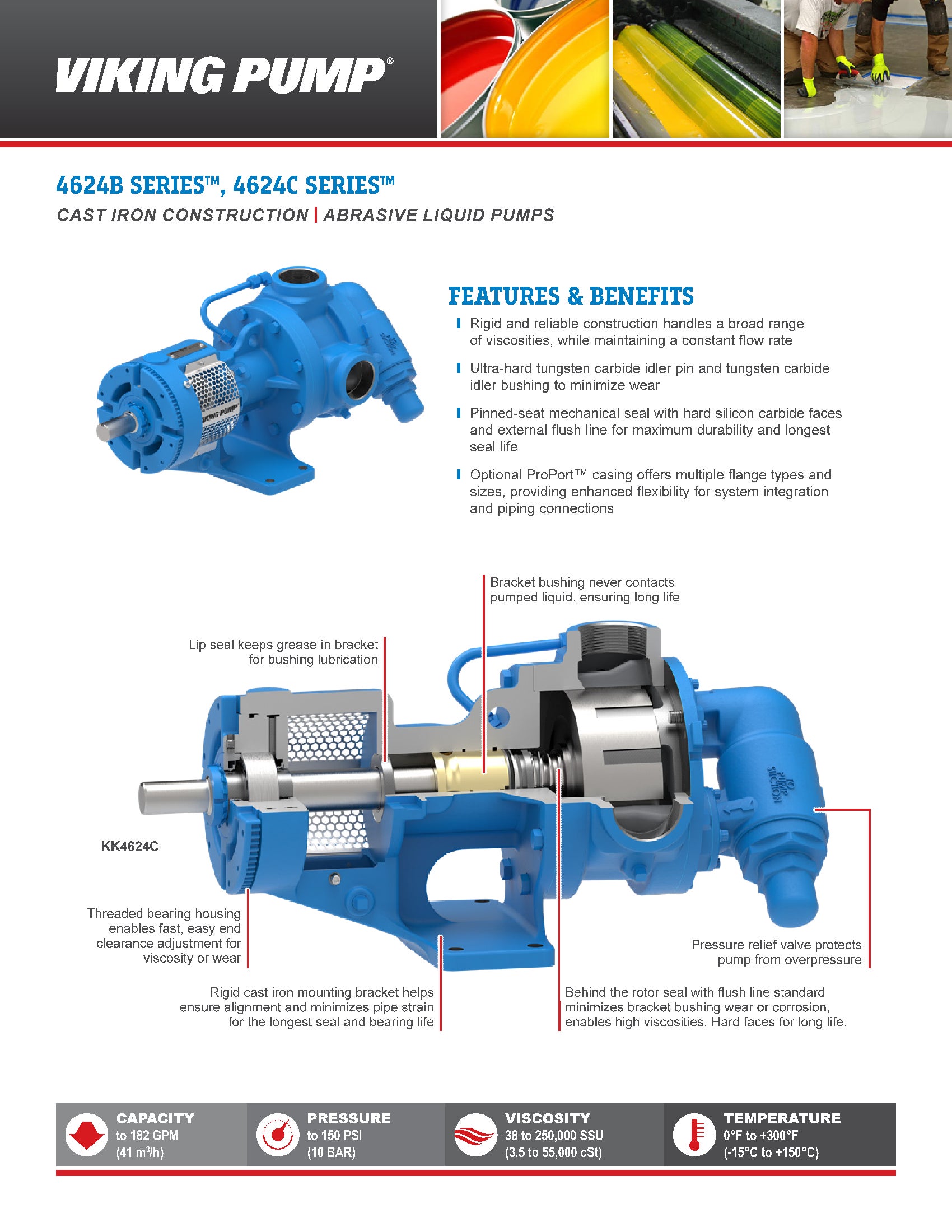

Features & Benefits

- The grease-filled bracket helps to prevent air and moisture from reaching the seal faces, which helps limit crystallization of some air or water-reactive liquids

- Ultra-hard tungsten carbide idler pin and tungsten carbide idler bushing minimize wear in this key area, since a constant supply of abrasive material is flowing through the pumping elements

- U-Plus™ Bracket comes standard with stainless steel window guards that offer protection from rotating parts

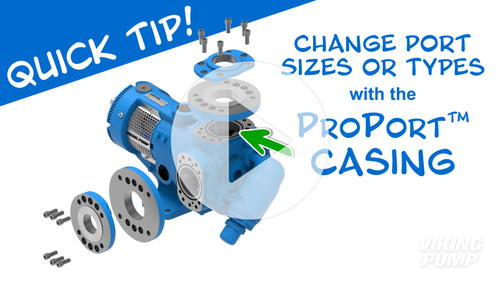

- Optional ProPort™ Casing adaptable port design offers a variety of port sizes and types, enabling flexibility when connecting pumps to piping

Capacity

5 to 182 GPM

1.1 to 41 m³/h

Viscosity

38 to 25,000 SSU

3.5 to 55,000 cSt

Pressure

150 PSI

10 BAR

Temperature

0 to +300°F

-15 to +150°C

Options

Porting

Drives

Mounting

Sealing

Specifications

| Model | Standard Port Size | Nominal Pump Rating (GPM) | Nominal Pump Rating ( m³/h) | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H4624C | 1.5 in | 5 GPM | 1.1 m³/h | 640 RPM | 400 PSI | 28 BAR |

| HL4624C | 1.5 in | 10 GPM | 2.2 m³/h | 640 RPM | 400 PSI | 28 BAR |

| K4624C | 2 in | 25 GPM | 5.6 m³/h | 280 RPM | 400 PSI | 28 BAR |

| KK4624C | 2 in | 35 GPM | 8 m³/h | 280 RPM | 400 PSI | 28 BAR |

| L4624C | 2 in | 50 GPM | 11 m³/h | 230 RPM | 400 PSI | 28 BAR |

| LL4624C | 3 in | 65 GPM | 15 m³/h | 230 RPM | 300 PSI | 21 BAR |

| LS4624C | 3 in | 72 GPM | 16 m³/h | 230 RPM | 300 PSI | 21 BAR |

| Q4624C | 3 in | 110 GPM | 25 m³/h | 190 RPM | 250 PSI | 17 BAR |

| QS4624C | 6 in | 182 GPM | 41 m³/h | 190 RPM | 250 PSI | 17 BAR |

Videos

Paints

Paints are shear sensitive liquids that can have a variety of solvents & pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

Inks

Inks for flexible packaging are shear sensitive liquids that can have a variety of solvents, waxes, surfactants, and semi-solid resin particles, and pigment load concentrations that bring with them abrasive wear and chemical compatibility concerns.

Polyol

Alcohols having many hydroxyl radicals are called polyols. Many companies market polyols under their own trade names. Product viscosity varies greatly depending on the specific polyol, but can be as thick as 40,000 cP. Polyols are often blended with isocyanates, so pumps handing polyols are often requested to be built using isocyanate compatible lubricants.

Resins

Resins are high viscosity liquids with potentially shear sensitive (thinning) components, and made up of solvents, waxes, surfactants, and semi-solid resin particles all with various chemical compatibility concerns. These resins can be used in polyurethanes, epoxies and other adhesives. In some cases, resins contain pigments that bring with them abrasive wear concerns.

-

DRAWINGS

H-HL with Plain Head - 1.5" NPT RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" NPT RH/LH PDF

STEP

H-HL with ProPort Casing - 2" Class 150 ANSI RH/LH PDF

STEP

H-HL with ProPort Casing - 2" Class 300 ANSI RH/LH PDF

STEP

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" NPT RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 2" Class 150 ANSI RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 2" Class 300 ANSI RH/LH PDF

STEP

K-KK with Plain Head - 2" NPT RH/LH PDF

STEP

K-KK with Plain Head - 4" Class 125 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 2" Class 125 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 2" Class 250 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 2" NPT RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

K-KK with Relief Valve - 2" NPT RH/LH PDF

STEP

K-KK with Relief Valve - 4" Class 125 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 2" Class 125 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 2" Class 250 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with Plain Head - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

STEP

L with ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

STEP

L with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

L with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

L with Relief Valve - 2" NPT RH/LH PDF

STEP

L with RV and ProPort Casing - 2" NPT RH/LH PDF

STEP

L with RV and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

Q with Plain Head - 4" Class 125 ANSI RH/LH PDF

STEP

Q with ProPort Casing - 4" Class 125 ANSI RH/LH PDF

STEP

Q with ProPort Casing - 4" Class 250 ANSI RH/LH PDF

STEP

Q with Relief Valve - 4" Class 125 ANSI RH/LH PDF

STEP

Q with RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

STEP

Q with RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

STEP

One Pump. Endless Configurations. Zero Compromises.

Viking's Next Generation Universal pumps use modular design to give you more options with fewer parts reducing your inventory complexity.

Viking Pump's U-Plus™ Bracket

-

Accepts a variety of seal types to meet your needs

-

Stainless steel window guards offer protection from rotating parts

-

Footed one-piece iron bracket provides rigid mounting to help maintain alignment, which extends seal and bearing life

Viking Pump's ProPort™ Casing

-

Adaptable port design offers a variety of port sizes and types, simplifying integration into existing piping systems and enhances installation efficiency

-

H-Q sizes available with optional opposite porting

-

Casing drain allows the pump to be drained without removing the head

-

Optional O-ring joint seals for high pressure of difficult to seal applications