Latex

Latex

Custom Content One

Latex is the generic term for emulsions of polymer in water that is stable. These emulsions can be natural or synthetically made. This liquid is typically very shear-sensitive and requires care when pumping.

Natural latex is a milky fluid containing isoprene found in plants, particularly rubber trees, and is usually dip molded to produce tubing, gloves, balloons and other products, although it may be dried to produce sheet goods suitable for compression molding. Synthetic latex, also known as emulsion polymers or polymer dispersions, is a stable suspension of microscopic polymer particles distributed throughout a water-based liquid. The polymers are made by reacting monomers like styrene and butadiene, although other synthetics include acrylics, polychloroprenes, nitriles, PVAs and many more. Synthetics are used in paints and coatings, adhesives, asphalts, cement and rubber products, to name a few.

Latex is typically non-Newtonian, shear thinning (as shear stress increases, viscosity decreases), however shear can also negatively impact the desired qualities so must be avoided. Viscosities can range from 2,000 to 20,000 cPs depending on solids concentration and temperature. Specific gravity typically ranges from 1.0 to 1.2.

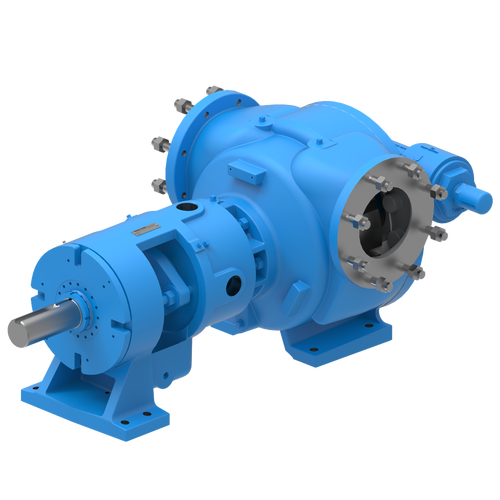

Positive displacement pumps, particularly internal gear pumps and lobe pumps, are preferred for latexes due to their ability to handle high viscosities, provide very low shear due to large cavities created between gear teeth or lobes with slow operating speeds, as well as the ability to adjust flow rate in proportion to pump speed for easy process control.

Custom Content One

Viking in the Process

Viking pumps are used to recirculate natural latex throughout dip tanks making molded products. They are used extensively in synthetic latex processing (monomer blending, reactor discharge) and railcar loading/unloading, as well as metering into downstream processes, particularly paints, coatings, adhesives and polymer-modified asphalt.

Custom Content Two

Applications

- Natural latex recirculation

- Synthetic latex processing and metering

- Viking in the Process

Recommended Pumps

-

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

-

1124A Series™

- Cast Iron

- O-Pro® Seal

- 15-500 gpm | 1.8-91 m3h

-

4327A SERIES™

- Stainless Steel

- Mechanical Seal

- 320-1600 gpm | 114-364 m3h

Articles / Case Studies

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025