Dyes

Dyes

Custom Content One

Positive displacement gear pumps are ideal for transferring dyes due to their ability to provide a consistent and precise flow rate, regardless of the system pressure. This advantage ensures that the dye is transferred smoothly and evenly, minimizing the risk of color inconsistencies in the final product. The design of gear pumps allows them to handle a wide range of viscosities, making them versatile when dealing with different dye formulations. Additionally, their robust construction ensures reliable operation with minimal maintenance, reducing downtime and operational costs. These characteristics make positive displacement gear pumps a preferred choice for industries requiring the efficient and accurate handling of dyes.

Recommended Pumps

-

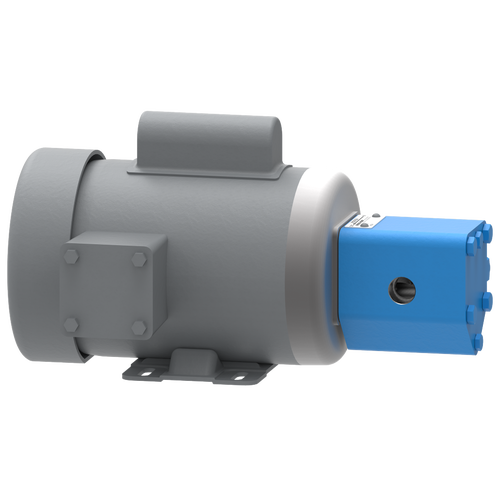

8124A SERIES™

- Cast Iron

- Mag Drive

- up to 500 gpm | up to 114 m3h

-

8127A SERIES™

- Stainless Steel

- Mag Drive

- up to 500 gpm | up to 114 m3h

-

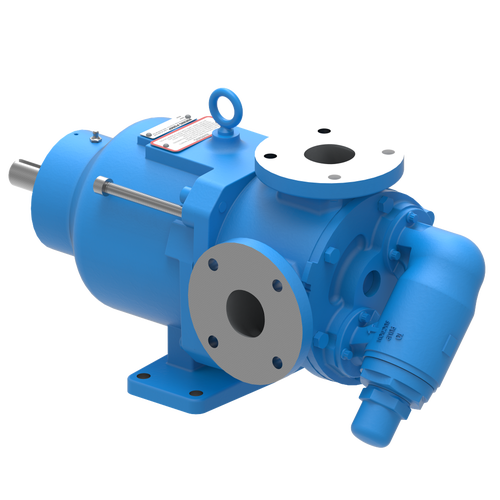

SG SERIES™

- Ductile Iron

- Mechanical Seal

- up to 190 gpm | up to 43 m3h

Articles / Case Studies

Discover how a fuel distributor in Ireland overcame pump reliability issues with Viking Pump’s SG805 Mag Drive solution—boosting efficiency, reducing maintenance, and ensuring compliance in a demanding fuel dye injection process.

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their dynamically-sealed cousins with...

Videos

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025

Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025