PUMP SOLUTIONS

Heading

INDUSTRIAL SOLUTIONS

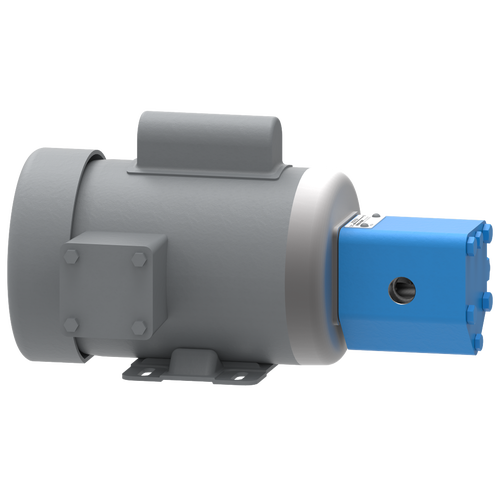

Viking Pump’s industrial gear pumps are the premiere positive displacement pump technology that covers nearly every pumping need.

Heading

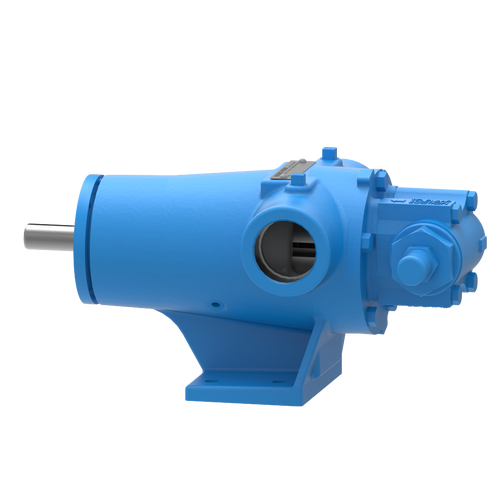

ENERGY SOLUTIONS

With construction options that have been proven to work for light, medium, and heavy-duty applications, the versatility and popularity of positive displacement pumps lie in their relatively simple design, high efficiency, and consistent flow rates.

Heading

HYGIENIC SOLUTIONS

Viking Pump’s hygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reduce cross-contamination, we offer CIP (clean in place), SIP (sterilize in place), and COP (clean out of place) pumps to save you time and effort.

TECHNOLOGIES

Heading

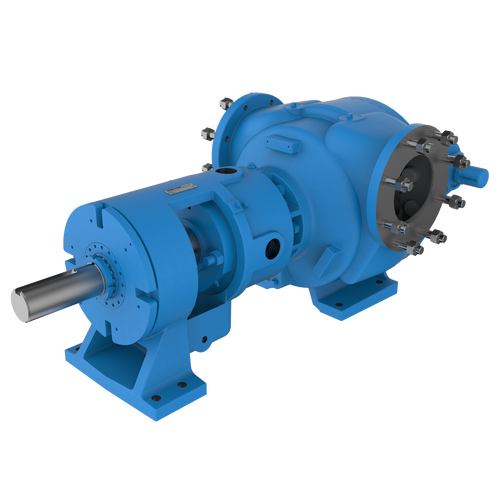

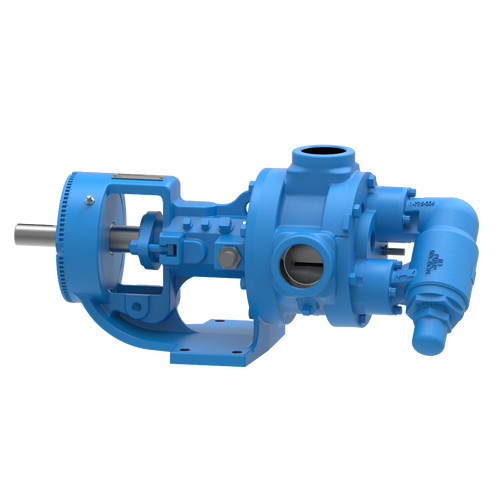

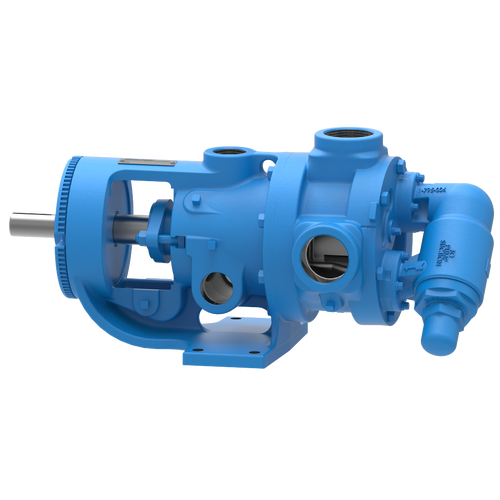

Internal Gear Pumps

Heading

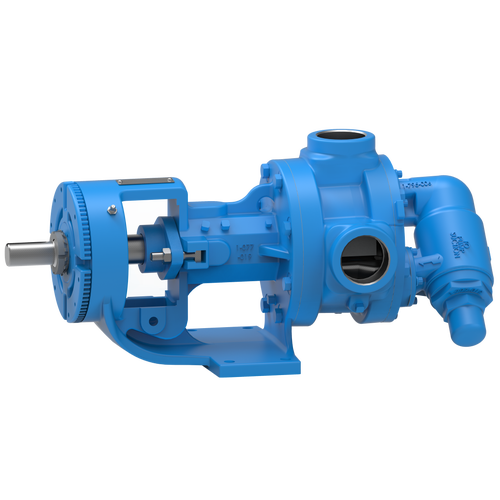

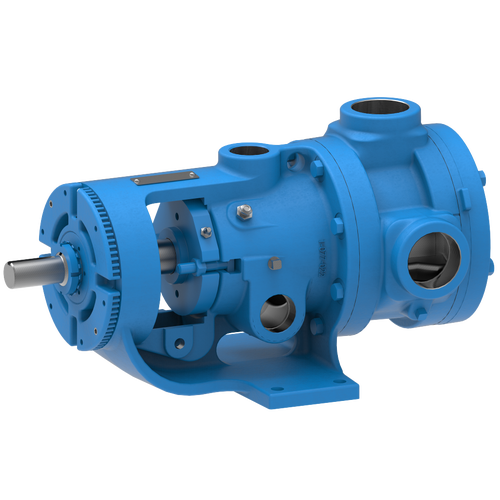

External Gear Pumps

Heading

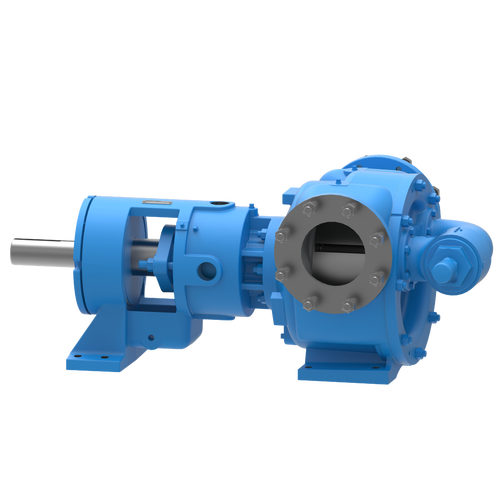

Circumferential Piston Pumps

Heading

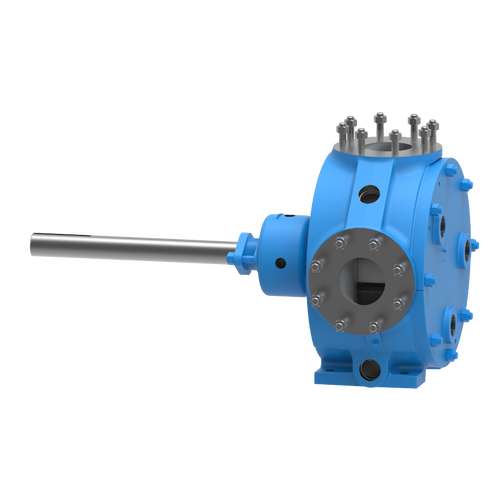

Rotary Lobe Pumps

Heading

Vane Pumps

FEATURED APPLICATIONS

Lube Oil (Machinery Lubrication)

Machinery lubrication pumps are used in everything from small backup generators to naval ships. Lube oils, as the name implies, are the liquids used to lubricate rotating and reciprocating machinery. Lube oils may be handled at higher pressures to ensure their penetration of the equipment.

- Ductile Iron

- Pressures up to 250 PSI

- Capacities to 190 GPM

- Cast Iron

- Pressures up to 250 PSI

- Capacities to 580 GPM

- Cast iron

- Compact installation

- Pressures up to 50 PSI

- Capacities to 30 GPM

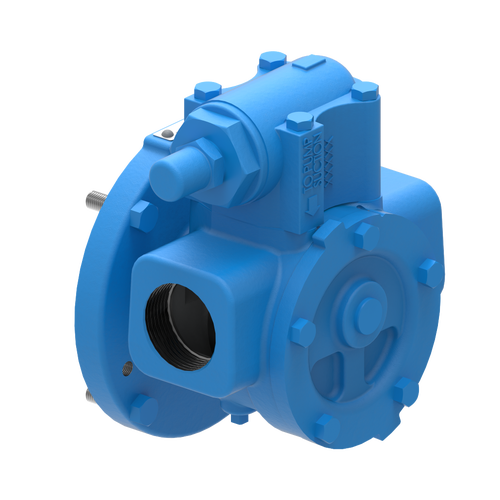

Lube Oil Blending

Local blending plants take bulk petroleum or synthetic base oils and mix them together with additives to create unique oil blends for specific applications and customers.

- Cast iron

- Abrasive resistant sealing option

- Hardened iron bushings and hardened steel shaft

- Capacities to 400 GPM

- Cast iron

- Sealless design

- Capacities to 500 GPM

- Ductile Iron

- Compact installation

- Capacities to 190 GPM

Asphalt Emulsions

Emulsions are asphalt suspended in a mixture with water or other liquids. This is done to ease the application of the asphalt. Uses would be crack filling, coating roadways, or waterproofing. These emulsions are shear sensitive and must be handled with care.

- Cast iron

- Jacketed for steam/oil heating prior to startup

- Mechanical seal options

- Capacities to 500 GPM

- Cast iron

- Ambient temperature

- Mechanical seal options

- Capacities to 500 GPM

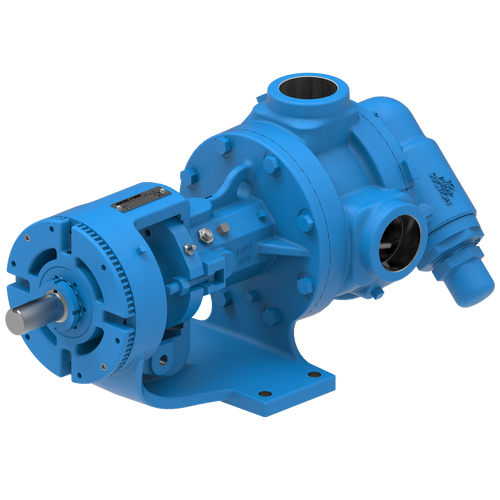

Asphalt Cement

Clean asphalt contains no fillers and is an oil based liquid. It is primarily used in paving roads, waterproofing liquids, and paints. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

- Cast iron

- Electric heating prior to pump startup

- Capacities to 1600 GPM

- Cast iron

- Jacketed for steal/oil heating prior to pump startup

- Lower pressures

- Capacities to 450 GPM

Filled Asphalt

Filled asphalts contain particulate used in the liquids’ end applications. Examples of this would be roofing materials and hot mix plants. Typically they are handled at elevated temperatures to reduce the viscosity of the asphalt mixture. The pump needs a source of heat like jacketing or electric heat to prevent the product from solidifying in the pump.

- Cast iron

- Jacketed for steam/oil heating prior to pump startup

- Capacities to 350 GPM

- Cast Iron

- Electric heating prior to pump startup

- Hardened material options

- Capacities to 500 GPM

Molasses

Molasses is defined as the syrupy mother liquor left after sucrose has been removed from the cane juice by concentration. If only one crop of crystals had been removed, it is called First Molasses. If the second crop has been removed, the product is termed Second Molasses, and so on. When no more cane sugar can be extracted it is called Final Molasses or Black Strap Molasses.

- Cast iron

- Jacketed for steam/oil prior to pump startup

- Leak prevention with O-Pro® Barrier seal

- Capacities to 500 GPM

- Stainless steel externals

- Jacketed option for steam/oil prior to pump startup

- Leak prevention with O-Pro® Barrier seal

- Capacities to 320 GPM

- Cast iron

- Jacketed for steam/oil prior to pump startup

- Hardened material options

- Capacities to 500 GPM

LEADING THE WAY IN GLOBAL SERIVCE

From pump configuration support to competitive quotes, the support team provided by our Viking Pump India team is the first step to complete your project. With the support of Viking's engineers, our team is ready to help you overcome your pumping challenges.

Articles & Case Studies

Viking Pump Industrial Tests New Modular Design at Stepan Company’s UK Facility

A loyal customer of Viking Pump® for 15 years, Stepan agreed to beta-test one of the latest pumps from our new Universal Product Line (4227C Series™) at their UK chemical manufacturing plant. Michael Smith Engineers is the local Viking Pump distributor, who initially approached Stepan as a likely pilot candidate due to a longstanding supplier-buyer relationship. Together, they set up the trial to demonstrate how...

All You Need to Know About ProPort™ Casings

Viking Pump’s new generation of internal gear pumps offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of porting flexibility. These new pumps reduced the number of casing configurations, which helps reduce manufacturing complexity, cost and lead times, while at the same time increasing the number of porting options and providing greater porting flexibility.

Expanded Seal Flexibility with U-Plus™ Brackets

Viking Pump’s new generation of pumps (sizes H-QS in steel and stainless steel) offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of sealing flexibility. These new pumps increase the number of sealing options possible in one pump, while at the same time reducing cost and lead times.

Exploring the Versatility of the U-Plus™ Bracket and ProPort™ Casing in Gear Pumps

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Asphalt Emulsion Pumping Application: Overcoming Challenges in Construction

Discover how Viking Pump India helped solve complex challenges in a mobile asphalt emulsion project in India through early technical collaboration and standardized gear pump solutions.

Monomer Pumping Application: Innovating for High-Viscosity Fluids

Learn how Viking Pump helped India’s leading ABS plastic producer overcome challenges in pumping high-viscosity, high-temperature fluids with a customized internal gear pump solution.

ABOUT US

INNOVATIVE PUMPING SOLUTIONS FOR ANY APPLICATION

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary positive displacement pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry-from military, to food and beverage, to chemicals, fuels and plastics-reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.