Fruit

Fruit

Custom Content One

Fruits pieces are used in a wide variety of food products. Fruits commonly used in food processing include apples, peaches, apricots, berries, grapes, citrus, pineapples, bananas, guavas, mangoes, papayas and passion fruit.

Fruits and fruit slurries and fillings are used in a wide variety of commercially processed food products, such as baked goods like fruitcakes, tarts, pies, pastries and muffins; confections like chocolates, ice cream, yogurt and cereal bars; jams and jellies; as well as fruit juices and wine.

Stainless steel hygienic gear pumps are ideal for processing fruit due to their exceptionally large cavities, sanitary properties and durability. The cavities created between rotors protect sensitive fruit solids from crushing or damage. Stainless steel is inherently resistant to corrosion and can withstand the acidic nature of fruit. These pumps are designed to meet stringent hygiene standards, often featuring smooth surfaces and crevice-free construction to minimize the risk of bacterial growth, and can be easily strip cleaned or cleaned in place. Their ability to handle the viscous and sometimes abrasive nature of fruit purees and juices ensures efficient and gentle transfer without compromising the product's quality. When paired with variable speed drives, the pumps’ flow rates can be adjusted automatically to match the speed of the processing line.

Custom Content One

Viking in the Process

Viking hygienic pumps are used at fruit processors to transfer fresh fruit cubes, slices, pulp, purées and sacs from the processing machine to blending with syrups or spices, pasteurization and on to canning, bulk packaging or transport.

They are also used at commercial bakeries, dairies, confectioners and other food processors to transfer processed fruit from receiving to depositor machines where the product is deposited into pastries or other products, as well as at beverage manufacturers and wineries to transfer juice and must to blending or fermentation.

Custom Content Two

Applications

- Fruit processing

- Transfer to depositor

Recommended Pumps

-

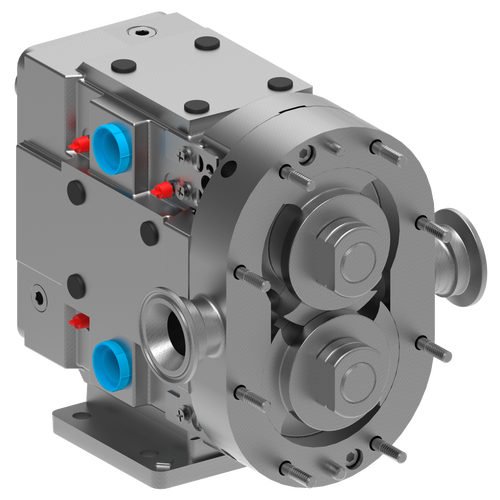

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

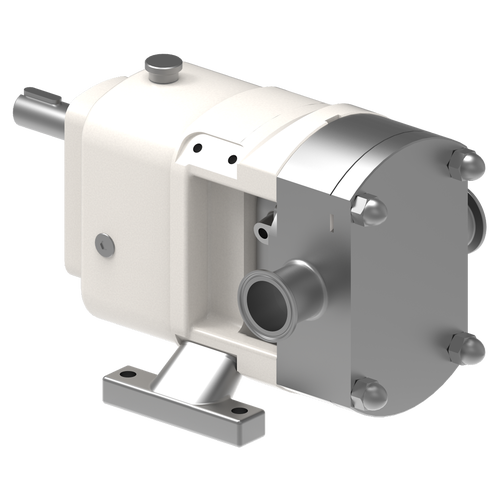

TRA®10 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

-

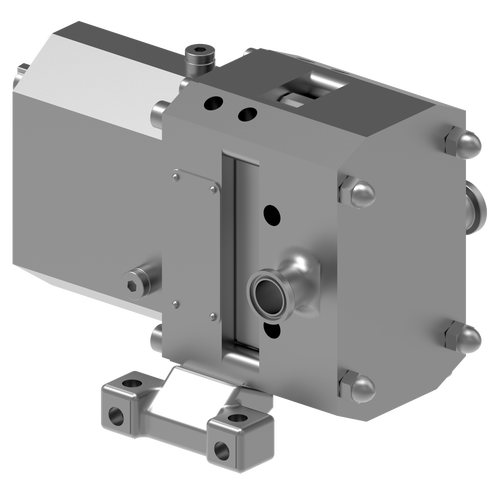

STERILOBE® SERIES

- Stainless Steel

- Mechanical Seal

- up to 753 gpm | up to 171 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025