Collagen

Collagen

Custom Content One

Collagen is a structural protein found in skin and other connective tissues. It can be used in a wide range of applications ranging from food products such as sausage skins to dietary supplements and cosmetics.

Hygienic positive displacement pumps are crucial in collagen production. They ensure gentle handling to preserve collagen integrity and quality. These pumps provide precise and consistent flow rates, essential for uniform collagen products in food, pharmaceuticals, and cosmetics. Their sanitary design minimizes contamination risks, keeping collagen products pure and safe. The ease of cleaning, thanks to their design, meets strict hygiene standards. Additionally, they handle various fluid viscosities as well as soft solids, managing different collagen manufacturing stages effectively. Overall, they ensure efficient, safe, and contamination-free production, making them ideal for the industry.

Custom Content One

Viking in the Process

Collagen Processing:

Collagen is made from bovine, porcine, equine or other hides. While some hides are processed into leather, much is processed into soluble collagen, fibrillar materials or thermoplastic collagen, which are used in food and cosmetic processing. Coarsely ground fibrillar materials may be pumped to colloid or ball mills, to acid or enzymatic hydrolysis tanks, to fat and solids separation via centrifugation, and to filtration and ultrafiltration, ion exchange and drying.

Downstream Applications:

Viking pumps are used to transfer collagen dispersions in food processing, in sausage casing manufacturing; for transfer in cosmetic manufacturing and environmental remediation as settling and filtration aids.

Custom Content Two

Applications

- Collagen processing

- Collagen dispersion transfer in downstream applications

Recommended Pumps

-

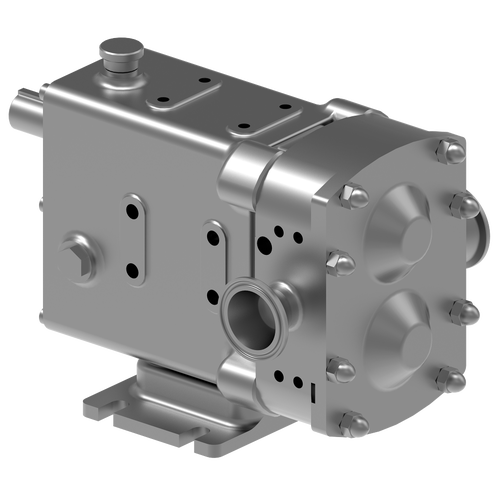

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

-

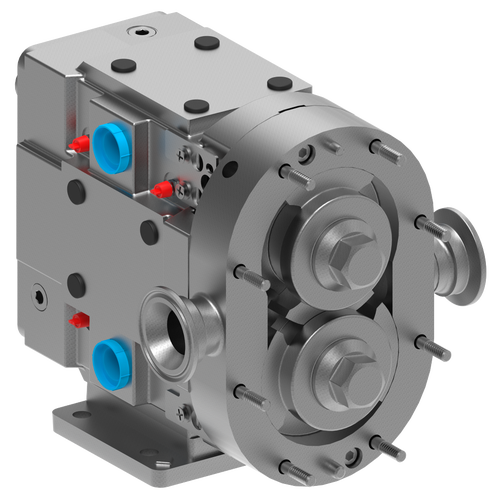

TRA®20 SERIES

- Stainless Steel

- Mechanical Seal

- up to 450 gpm | up to 102 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025

- Welcome to Viking Pump's FoundryThis is Viking Pump’s foundry in Cedar Falls, Iowa. For decades, the Viking Pump foundry has been a pillar of our vertical integration capabilities – allowing for the nimble production of castings and parts to satisfy customer needs and support new product development.February 14, 2025