Alcohols

Alcohols

Custom Content One

Positive displacement pumps are ideal for transferring alcohols due to their ability to handle a wide range of viscosities and their precision in delivering consistent flow rates regardless of the pressure conditions. These pumps operate by trapping a fixed amount of fluid and forcing it through the discharge pipe, making them particularly effective in maintaining the integrity of volatile and sensitive fluids like alcohols. Additionally, their robust design reduces the risk of cavitation, ensuring that the alcohol is transported without undesirable frothing or turbulence. Their ability to maintain consistent pressure and flow also helps in minimizing the risks of contamination and degradation, making them a reliable choice for industries that deal with alcohols, such as the beverage, pharmaceutical, and chemical sectors.

Custom Content One

Viking in the Process

Viking pumps are used in wide variety of different processes in the transfer, blending and metering of alcohols. Alcohol applications involving Viking pumps range from methanol, butyl alcohol, isopropyl alcohol and beyond. With methanol, Viking pumps are used for blending in production of formaldehyde, for automobile antifreeze, and for transfer as a general solvent. Viking pumps in Butyl Alcohol applications are used for blending and transfer in the preparation of esters and butyl acetates, along with blending/metering as a solvent in resins and coatings. With isopropyl alcohol, Viking pumps are used for blending and transfer in a large number of liquids, such as: deicing agents, perfumes, lacquers, pharmaceuticals, and resins. Viking pumps are used to transfer ethyl alcohol that is used in the manufacture of fuels, disinfectants, solvents and other organic compounds.

Custom Content Two

Alcohol Applications

- Bulk transfer

- Blending

- Intermediate Transfer

- Metering

Recommended Pumps

-

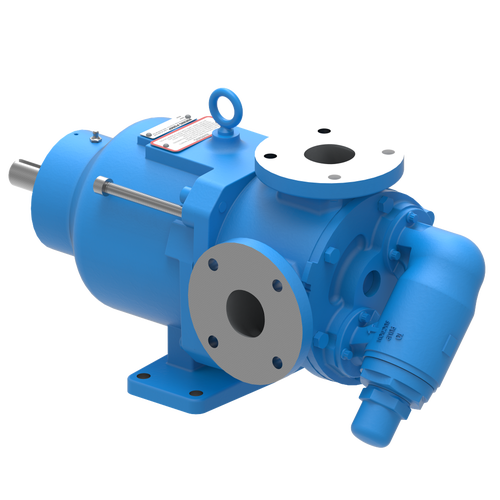

4197 SERIES™

- Stainless Steel

- Mechanical Seal

- up to 75 gpm | up to 17 m3h

-

8127A SERIES™

- Stainless Steel

- Mag Drive

- up to 500 gpm | up to 114 m3h

-

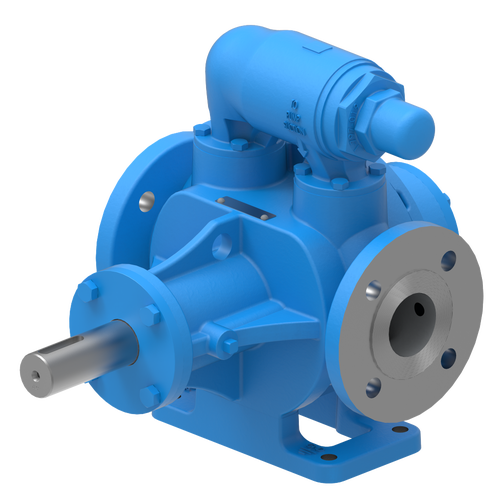

LVP SERIES™

- Stainless Steel

- Mechanical Seal

- up to 160 gpm | up to 36 m3h

Articles / Case Studies

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their dynamically-sealed cousins with...

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025