Additives

Additives

Custom Content One

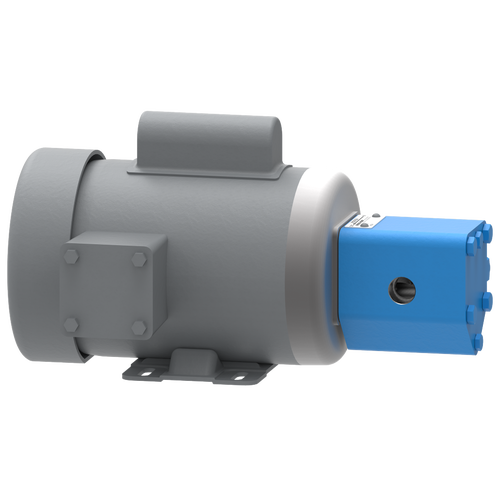

Positive displacement pumps are particularly well-suited for transferring additives due to their ability to handle a wide range of viscosities and maintain a consistent flow rate, even under varying pressure conditions. These pumps operate by trapping a fixed amount of fluid and displacing it through the pump's discharge, which ensures precise and accurate dosing of additives. This level of control is crucial when dealing with substances that require consistent and accurate quantities to ensure the desired chemical reaction or product quality.

Viking pumps are used for metering when required flow rates or pressures exceed those available from smaller diaphragm-type metering pumps. In continuous processes, additive pumps are commonly driven by a variable speed drive controlled by an input signal from a flowmeter on the line they are being metered into to provide flow in proportion to the flow of that liquid. For batch processes, additive pumps with standard motors are commonly turned on and off by batch controllers based on input signals either from flowmeters downstream of the pumps or from load cells on the tank they are discharging into.

Additives have a wide range of characteristics, some viscous, some thin; some highly lubricating, some abrasive. Most additives are fairly inert and compatible with iron pumps, though some like red dye for diesel may need stainless steel to maximize life. Some food additives or colorants may require hygienic pump designs for cleanability. Viking offers all of these options.

Custom Content One

Viking In the Process

Fuel additives commonly handled by Viking pumps include oxygenates, antioxidants, stabilizers, antiknock additives and dyes, typically using magnetic drive spur gear pumps with explosion proof motors to meter into a gasoline or diesel stream at the refinery or terminal.

Lube oil additives include detergents, dispersants, antioxidants, anti-foam agents, and anti-wear additives. These are typically metered into blending tanks at lube oil plants using Viking internal gear pumps.

Polyurethane additives include catalysts, surfactants, blowing agents, chain extenders, cross-linkers and dyes. These are typically handled by Viking spur gear pumps to meter into a polyol and isocyanate stream at a foam plant.

Paint additives commonly include solvents, wetting agents, thickeners, anti-foaming agents, and biocides. They are typically metered into blending tanks at paint manufacturers using Viking internal gear pumps.

Viking also plays extensively in dosing additives across the chemical industry and the food and beverage industry, where they handle a very wide range of ingredients.

Custom Content Two

Addivites Applications

- Truck and Railcar Unloading

- Transfer to Day Tanks

- Metering into Process Streams

- Metering into Blending Tanks

Recommended Pumps

-

SG SERIES™

- Ductile Iron

- Mechanical Seal

- up to 190 gpm | up to 43 m3h

-

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

Articles / Case Studies

Discover how a fuel distributor in Ireland overcame pump reliability issues with Viking Pump’s SG805 Mag Drive solution—boosting efficiency, reducing maintenance, and ensuring compliance in a demanding fuel dye injection process.

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025