Acetone

Acetone

Custom Content One

Positive displacement pumps are ideal for transferring acetone due to their ability to handle low viscosity fluids with precision and efficiency. Acetone, a volatile and low-viscosity solvent, requires a pump with consistent and controlled flow and low NPSHr to minimize cavitation and ensure safety during transfer processes.

Unlike centrifugal pumps, positive displacement pumps are less sensitive to changes in flow conditions, making them reliable and efficient for the precise transfer of acetone across various industrial applications. Additionally, these pumps offer excellent priming capabilities, low NPSHr, handle a wide range of flow rates and provide signficant discharge pressures.

Acetone, C3H6O, is a flammable organic solvent with viscosity of 0.39 cSt and a specific gravity of 0.78. Vapor pressure is 4.4 PSI at 25ᵒC but 54 PSI at 100ᵒC, which must be considered in NPSHa calculations. It has low acute toxicity but can cause irritation to the eyes, skin, and respiratory system at high concentrations, though it is not considered a Volatile Organic Compound by the US EPA. Acetone is compatible with iron, steel and stainless steel, but has poor compatibility with some elastomers, so proper seal selection is critical. Its solvent properties and very low viscosity can result in wear on sliding metal gears and bushings, and can cause swelling in PEEK vanes, so lobe or circumferential piston pumps with non-contacting rotors and bearings external to the liquid are recommended for longest life.

Custom Content One

Viking In the Process

Viking pumps are used in wide variety of different processes in the transfer, blending and metering of acetone both as a solvent and as a chemical intermediate. Solvent applications include transfer and metering in paint, ink and resin manufacturing. Chemical applications include transfer and metering of acetone as a precursor to methyl methacrylate and Bisphenol A.

Custom Content Two

Common Applications

- Railcar Unloading

- Bulk Transfer

- Blending

- Metering

Recommended Pumps

-

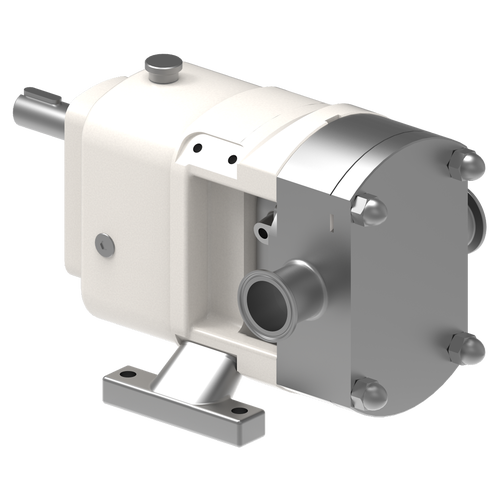

CLASSIC+ SERIES™

- Stainless Steel

- Mechanical Seal

- up to 832 gpm | up to 189 m3h

-

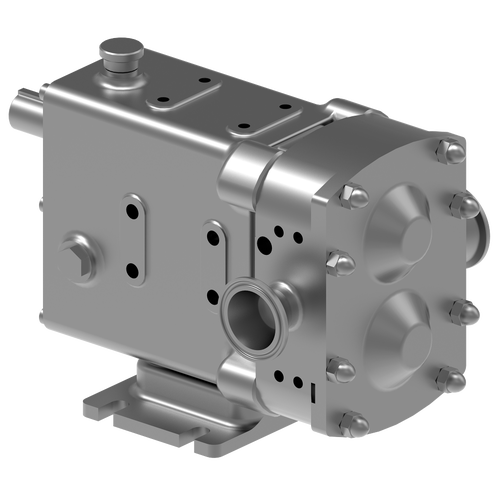

REVOLUTION® SERIES

- Stainless Steel

- Mechanical Seal

- up to 400 gpm | 1.8-91 m3h

Articles / Case Studies

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no best source for everyone – each has advantages and disadvantages depending on your situation and budget. Here are some points to consider when choosing where to source your pumps.

Viking Pump invented the internal gear pump in the early 20th century; but did you know that we carry various other pump technologies? Most of them are easily identifiable based on their shape. But one common mistake… read more.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025