Heat Transfer Liquids (Hot Oil)

Heat Transfer Liquids (Hot Oil)

Custom Content One

Heat transfer fluids (HTF), also known as heat transfer oil (HTO) or hot oil, is used for transferring heat from a heater to an point of use such as chemical reactors or injection molding, as well as in food applications like bakeries.

HTFs are generally made from mineral oil, glycols or silicone oil. They exhibit high thermal stability in order to resist degradation with large temperature swings, as well as high heat capacity and thermal conductivity. At operating temperature they have very low viscosity, but at ambient temperatures they can be quite viscous, which is why positive displacement pumps are needed.

Positive displacement pumps are ideal for loading and makeup of cold heat transfer liquids due to their ability to handle high viscosity fluids. These pumps operate by trapping a fixed amount of fluid and forcing it through the pump, making them highly efficient for transferring viscous fluids like cold HTF. Additionally, positive displacement pumps can handle a wide range of temperatures and viscosities, ensuring safe and reliable operation for recirculation at temperature, utilizing overpressure protection to ensure safety. Their robust construction and ability to provide an easily controllable flow rate make them a preferred choice for handling heat transfer liquids in various industrial applications.

Custom Content One

Viking in the Process

Viking pumps in heat transfer systems eliminate the need for a second loading pump, because the same pump can be used for both loading cold, high viscosity HTF and for recirculating thin, hot HTF at temperatures to 450ᵒF. Consult Viking for seal selection.

Custom Content Two

Applications

- Heat transfer system loading and makeup, recirculation

Recommended Pumps

-

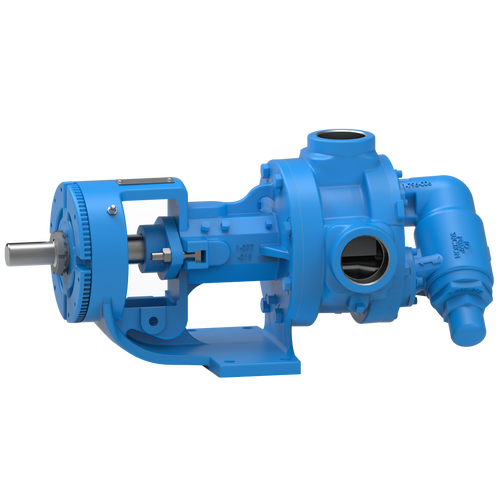

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

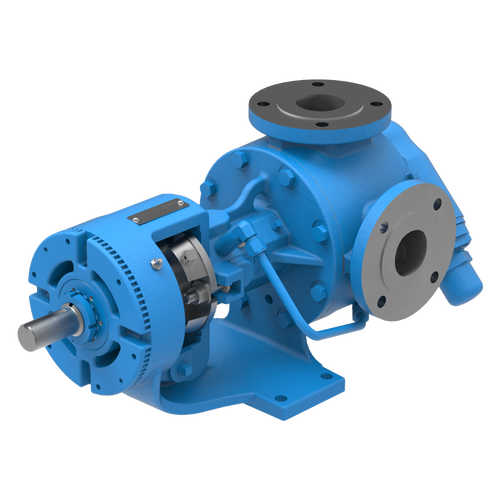

4224A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

4123A SERIES™

- |

Articles / Case Studies

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Unlike most of my colleagues I didn’t start out with a mechanical background. While they were studying kinetics and machine design, I was studying digital electronics and industrial power. When I started my career in the world of pumps, I had to learn a whole new set of concepts. What was surprising was that while the terminology may be a bit different, the concepts are very similar. Think of the following as a “Rosetta Stone” for translating the common terms and concepts of fluid systems to your more familiar terms and concepts of electrical systems.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025