Filled Asphalt

Filled Asphalt

Custom Content One

Filled asphalts contain particulate and are used to manufacture asphalt roofing. The filler material improves durability and fire resistance of the shingle. Pumping filled asphalt requires special construction and operation to minimize abrasion, prevent leakage and extend pump life.

The asphalt used in roofing is typically polymerized and/or oxidized (blown) for increasing weather resistance. Viscosity at operating temperature may range from 1,000 to 10,000 cPs, and when blended with up to 70% stabilizer (usually crushed limestone filler) is extremely abrasive. In this process reliability is critical.

Positive displacement pumps are well suited to this task due to their ability to handle viscous, abrasive, high temperature liquids. Their ability to adjust flow rate using a variable speed drive enables automatic flow control to match the speed of the looper.

Filled asphalt pumps must be jacketed for steam or hot oil heat, or electrically heated to ensure that the asphalt is liquified prior to startup. For longest life, they should be fitted with hard bushings and idler pin and operated at slow speeds to resist abrasion. Jacketed pressure relief valves are recommended as well. They may feature packed gland, or some users have found success using specialized cartridge seals and seal plans available from Viking. These pumps feature the ability to change sealing options as needed, as well as to adjust clearances to compensate for abrasive wear over time.

Custom Content One

Viking in the Application

Viking pumps are used throughout the shingle manufacturing process, from unloading flux from railcars, to transfer through the heater to blowing stills, to blending and pumping filled asphalts at the coater, to pumping adhesive and seal down asphalts.

The specially-fitted filled asphalt pumps are used to transfer material from the mix tank where stabilizer is added, to the coater, and then in a coater pan return application to recirculate filled asphalt through the pan to coat the fabric that becomes the shingle prior to addition of roofing granule and downstream application of seal down and adhesive asphalts, cutting and stacking.

Custom Content Two

Applications

- Filled Asphalt Transfer

- Coater Pan Return

Recommended Pumps

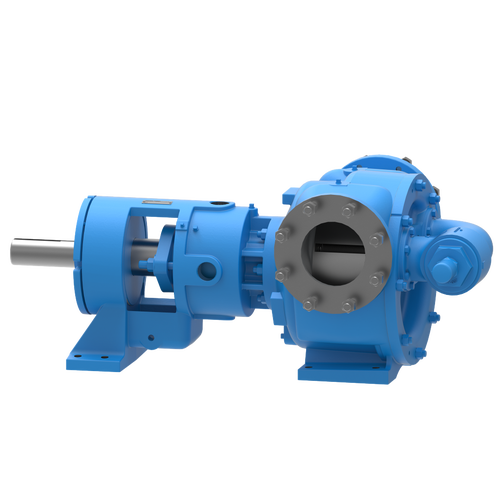

-

324A Series™

- Cast Iron

- Packing

- 500-1600 gpm | 114-364 m3h

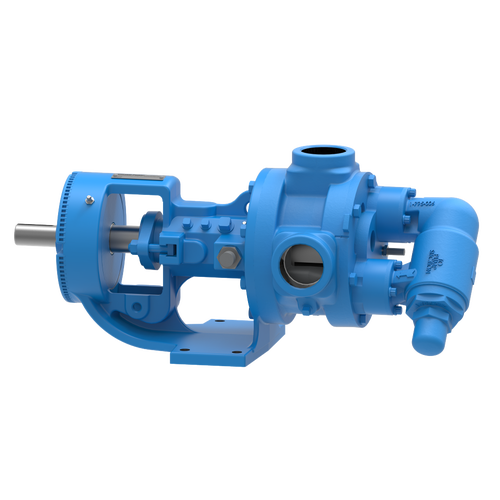

-

124E SERIES™

- Cast Iron

- Packing

- 320-1600 gpm | 114-364 m3h

Articles / Case Studies

The terms bitumen and asphalt are often used interchangeably, but they are two completely different materials, causing confusion inside and outside the industry. Throw in regional differences in meaning and language, and it’s time to set the record straight, along with tips on bitumen pump selection.

Viscosity is a measure of a liquid’s resistance to flow. And you don’t need to work in a laboratory to observe this. Anyone who’s spent any time in the kitchen has observed a variety of liquids with a wide variety of viscosities.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025