Beurre

Beurre

Custom Content One

Le beurre est une graisse comestible de couleur jaune pâle obtenue par barattage de la crème dans de grandes laiteries industrielles. Il peut être utilisé comme pâte à tartiner ou comme ingrédient dans la préparation et la cuisson des aliments, à la maison, dans les restaurants et dans la fabrication alimentaire commerciale/industrielle et les boulangeries.

Les pompes volumétriques hygiéniques

sont essentielles dans le traitement et le transfert du beurre en raison de leur capacité à traiter des produits visqueux de manière sûre et efficace tout en préservant l'intégrité et la qualité du produit. Ces pompes fonctionnent en piégeant une quantité fixe de crème ou de beurre et en la déplaçant à travers la pompe à chaque rotation ou cycle, assurant un débit constant sans causer de contrainte de cisaillement ni altérer la texture du beurre, même à des pressions élevées développées par les viscosités élevées. Leur conception privilégie l'hygiène et elles sont souvent composées d'acier inoxydable ou d'autres matériaux de qualité alimentaire, ce qui minimise les risques de contamination et respecte les normes d'hygiène strictes requises dans la transformation des aliments. De plus, la manipulation en douceur caractéristique des pompes volumétriques empêche le beurre de surchauffer, préservant ainsi ses propriétés naturelles et son goût. Cela en fait un choix idéal dans les industries où le maintien de la qualité et de la sécurité des produits est primordial.

Custom Content One

Viking dans le processus

Bien que les processus varient, le lait cru entrant est généralement pompé vers des séparateurs centrifuges où la crème est séparée du lait écrémé. Les pompes Viking sont utilisées pour transférer la crème plus visqueuse du séparateur vers un pasteurisateur afin de tuer les agents pathogènes, où elle est ensuite refroidie. Elle est ensuite pompée vers des cuves de maturation où des cultures bactériennes peuvent être ajoutées et où les molécules de graisse sont stabilisées. Cette crème refroidie et vieillie est ensuite pompée vers la baratte à beurre ou la centrifugeuse, où les graisses forment de petites boules de beurre qui se séparent du liquide, lequel est transformé en babeurre. Ce beurre très visqueux peut être pasteurisé à nouveau et pompé vers une malaxeuse qui rend le beurre lisse et crémeux, et où du sel peut être ajouté. Les pompes Viking transfèrent ensuite le beurre fini à travers des refroidisseurs vers des machines d'emballage où il est déchargé dans des pots ou extrudé à travers des filières pour former des bâtonnets.

Custom Content Two

Applications

- Transfert du lait – du réservoir de réception au séparateur

- Transfert de la crème – du séparateur au pasteurisateur, du pasteurisateur aux cuves de maturation, des cuves de maturation à la baratte

- Transfert du babeurre – de la baratte à la transformation ultérieure

- Transfert du beurre – de la baratte au malaxeur, transformation par malaxage

Recommended Pumps

-

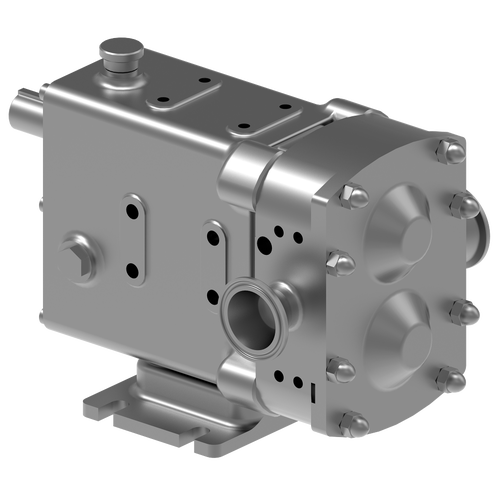

REVOLUTION® SERIES

- Acier inoxydable

- Garniture mécanique

- up to 400 gpm | 1.8-91 m3h

-

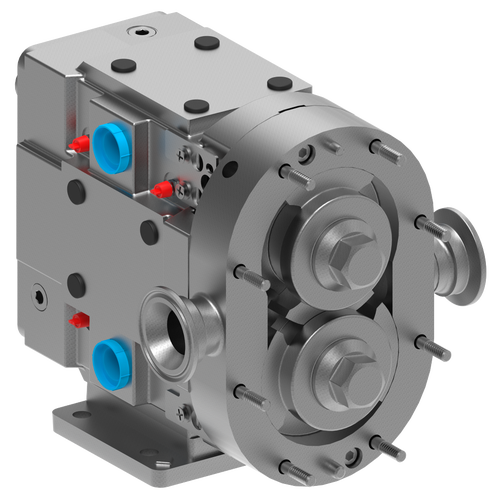

TRA®20 SERIES

- Acier inoxydable

- Garniture mécanique

- up to 450 gpm | up to 102 m3h

-

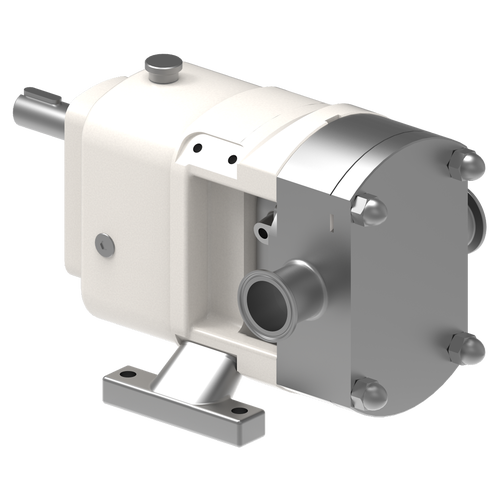

CLASSIC+ SERIES™

- Acier inoxydable

- Garniture mécanique

- up to 832 gpm | up to 189 m3h