Caustic (Sodium Hydroxide)

Caustic (Sodium Hydroxide)

Custom Content One

Sodium hydroxide is a strong base (pH 13–14) widely used in petroleum refining, chemical manufacturing, rayon and film production, pulp and paper, aluminum processing, vegetable oil, detergents, soaps, textiles, water treatment, rubber reclamation, and as an alkali in foods. It is primarily produced through the chloralkali process, initially as a 32% solution and then concentrated to 50%. Solid sodium hydroxide is also available in flakes, prills, and cast blocks.

Caustic soda’s viscosity ranges from water-thin at low concentrations to about 78 cP at 50%. It is denser than water, with a specific gravity of 1.5 at 50% and up to 2.0 at 72%, which must be considered in NPSHa calculations. Positive displacement pumps are ideal for transferring moderately viscous liquids like sodium hydroxide because they handle a wide range of viscosities and provide consistent, controlled flow. These pumps trap a fixed amount of fluid and force it through the system, ensuring steady flow even under varying pressures. Their excellent NPSHr characteristics make them suitable for difficult suction conditions, even with high specific gravity fluids.

Because caustic soda is highly corrosive, consult Viking for material recommendations, especially for higher concentrations or temperatures. To prevent severe chemical burns, mechanical seals or sealless magnetic drives are recommended.

Custom Content One

Viking in the Process

Viking pumps are found wherever caustic is used, especially in chemical manufacturing and saponification processes in soap and detergent manufacturing. Tank and railcar unloading is commonly performed via top of tank to prevent unintended spills that could come from tank bottom ports. Due to high specific gravity, this requires both the self-priming ability and excellent NPSHr provided by Viking pumps. Transfer pumps may be constant speed, controlled by level controls or load cells. Metering applications typically require variable speed drives.

Custom Content Two

Applications

- Tank/railcar unloading

- Transfer from tank farm to day tank

- Metering into process

Recommended Pumps

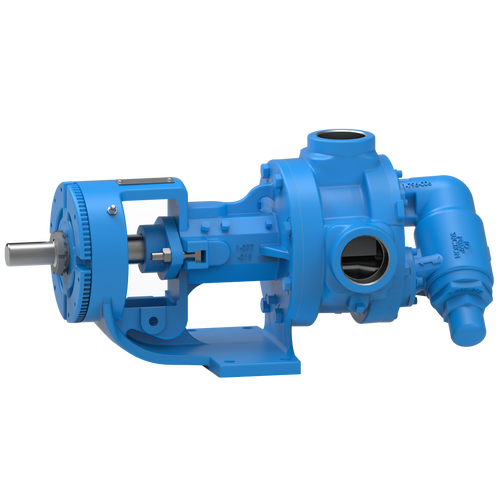

-

4124A SERIES™

- Cast Iron

- Mechanical Seal

- up to 500 gpm | up to 114 m3h

-

4127C Series™

- Stainless Steel

- Mechanical Seal

- up to 320 gpm | up to 73 m3h

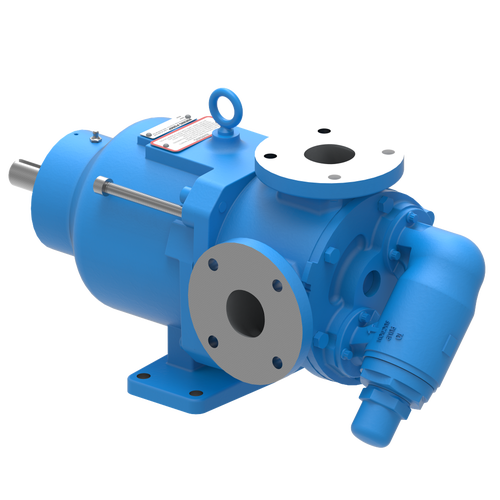

-

8127A SERIES™

- Stainless Steel

- Mag Drive

- up to 500 gpm | up to 114 m3h

Articles / Case Studies

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their dynamically-sealed cousins with...

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility and efficiency in your pumping process. Let’s dive into what makes these innovations stand out.

Videos

- How Pump Packing Works - AnimationIn this video, learn about pump packing and how it works.March 14, 2025

- Welcome to Viking Pump's Machine ShopThis is Viking Pump’s machine shop in Cedar Falls, Iowa. Continual investments in machines and people simplify and expedite production – enabling shipment for thousands of products every year.February 28, 2025