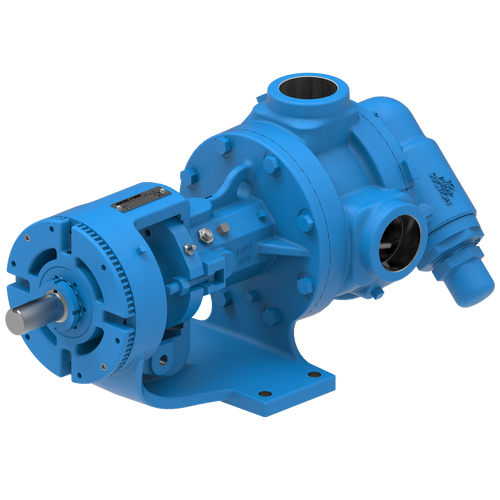

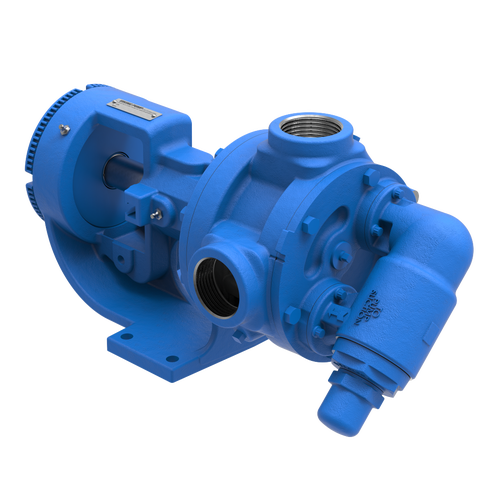

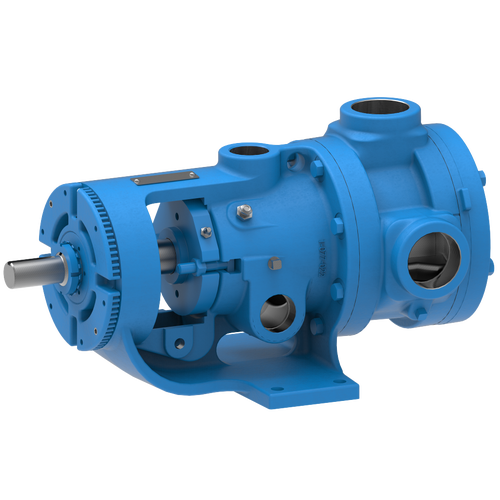

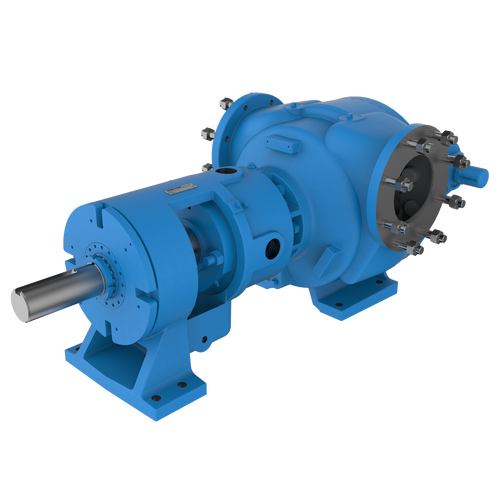

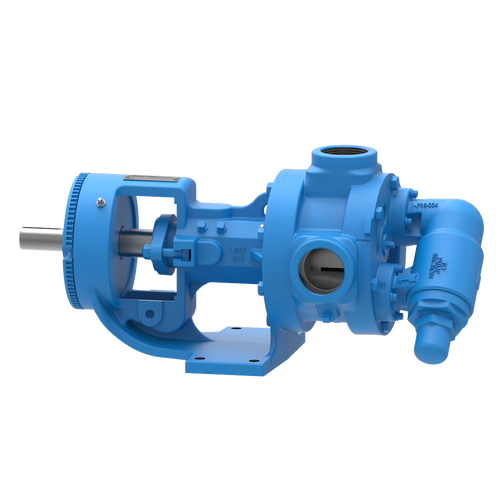

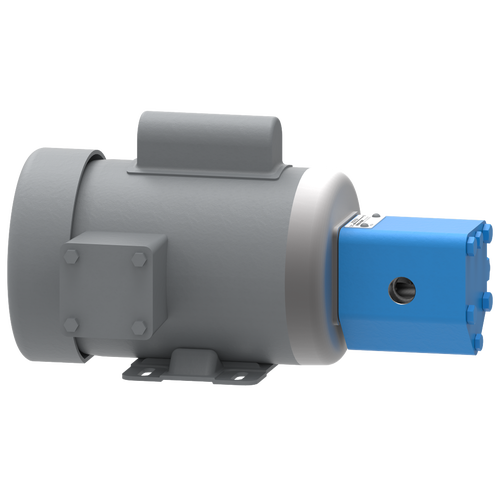

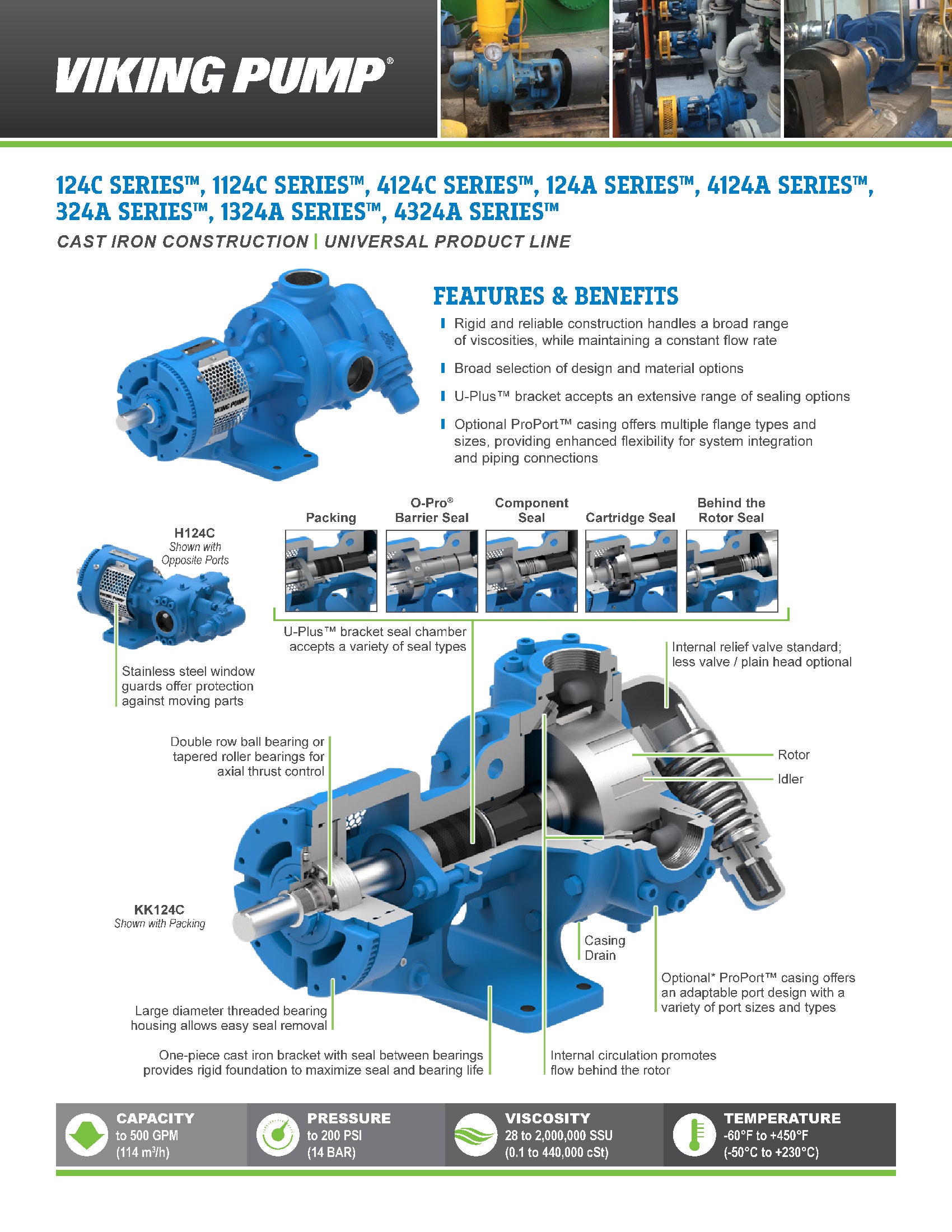

The 1124C Series™ internal gear pump is a cornerstone of Viking Pump's Universal Product Line, delivering exceptional reliability and versatility for a wide range of fluid handling applications. Featuring the innovative U-Plus™ bracket design, these pumps come standard with Viking's patented O-Pro® seal technology but have the ability to adapt to your ideal sealing needs.

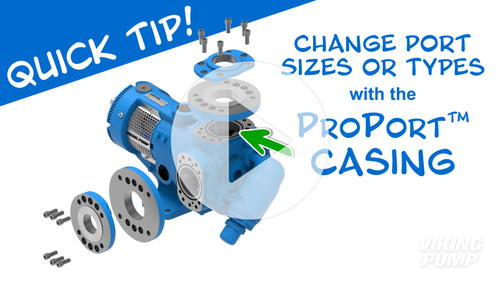

Designed for adaptability, the 1124C Series™ offers multiple configuration choices and is fully compatible with ProPort™ casings, providing flexible flange types, sizes, and port arrangements for seamless system integration. Ideal for applications such as lubrication systems, hydraulic oil circulation, chemical processing, fuel transfer, and more, the 1124C Series™ ensures dependable performance across diverse operating conditions.

Caractéristiques et Avantages

- Positive displacement internal gear pumping principle handles a wide range of viscosities with constant flow rate

- U-Plus™ Bracket adapts the pump's sealing solution to fit your needs.

- Optional ProPort™ Casing offers a variety of port sizes and types, simplifying integration into your existing piping systems

- Stainless steel window guards offer protection from rotation parts

Capacité

8 to 400 GPM

1.8 to 91 m³/h

Viscosité

100 to 75,000 SSU

20 to 17,000 cSt

Pression

to 200 PSI

to 14 Bar

Température

0 to +350 °F

-15 to +175 °C

Options

Raccords

Entraînements

Montage

Étanchéité

Spécifications

| Model | Standard Port Size | Nominal Pump Rating GPM | Nominal Pump Rating m3/h | Maximum RPM | Maximum Pressure PSI | Maximum Pressure BAR |

|---|---|---|---|---|---|---|

| H1124C | 1.5 inches | 8 GPM | 1.8 m3/h | 1000 RPM | 200 PSI | 14 BAR |

| HL1124C | 1.5 inches | 18 GPM | 4 m3/h | 1000 RPM | 200 PSI | 14 BAR |

| K1124C | 2 inches | 80 GPM | 18 m3/h | 780 RPM | 200 PSI | 14 BAR |

| KK1124C | 2 inches | 100 GPM | 23 m3/h | 780 RPM | 200 PSI | 14 BAR |

| L1124C | 2 inches | 135 GPM | 31 m3/h | 640 RPM | 200 PSI | 14 BAR |

| LL1124C | 3 inches | 140 GPM | 32 m3/h | 520 RPM | 200 PSI | 14 BAR |

| LS1124C | 3 inches | 200 GPM | 45 m3/h | 640 RPM | 200 PSI | 14 BAR |

| Q1124C | 4 inches | 275 GPM | 62 m3/h | 470 RPM | 200 PSI | 14 BAR |

| QS1124C | 6 inches | 400 GPM | 91 m3/h | 470 RPM | 200 PSI | 14 BAR |

Videos

Adhésifs

Les adhésifs sont un groupe de substances, telles que le ciment, la colle, le mucilage et la pâte, qui sont capables de maintenir des matériaux ensemble par fixation superficielle. Les adhésifs sont fabriqués à partir de nombreux matériaux de base différents, parmi lesquels la dextrine, le latex, les silicones, le caoutchouc liquide, la résine, le silicate de sodium et l'amidon.

Savon à la liqueur noire

Sous-produit intermédiaire naturel de la mise en pâte kraft, le savon à la liqueur noire est la colophane et les acides gras qui flottent à la surface lorsque la liqueur noire est laissée à l'état de décantation. Il est écrémé et peut être utilisé comme matière première pour la production de tall oil. Le savon à la liqueur noire peut être quelque peu abrasif et sa viscosité varie de 100 à 26 000 SSU, en fonction de la température à laquelle il est manipulé.

Calfeutrements

Les mastics peuvent être des adhésifs et des produits d'étanchéité à base de silicone, d'acrylique ou de latex utilisés dans la construction industrielle et résidentielle. Ils sont généralement très visqueux et sensibles au cisaillement.

Graisses

Communément appelée graisse de lubrification, graisse automobile ou graisse pour roulements. Il s'agit généralement d'un mélange d'huile minérale et d'un ou plusieurs savons métalliques, les plus courants étant ceux de sodium, de calcium, de baryum, d'aluminium, de plomb, de lithium, de potassium et de zinc. La texture de la graisse peut être lisse, onctueuse, rugueuse, fibreuse, spongieuse ou caoutchouteuse, et sa viscosité peut varier.

Isocyanate

-

DRAWINGS

H-HL with Plain Head - 1.5" NPT RH/LH PDF

STEP

H-HL with ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with Relief Valve - 1.5" NPT RH/LH PDF

STEP

H-HL with RV and ProPort Casing - 1.5" Class 125 ANSI RH/LH PDF

H-HL with RV and ProPort Casing - 1.5" Class 250 ANSI RH/LH PDF

K-KK with Plain Head - 2" NPT RH/LH PDF

STEP

K-KK with Plain Head - 4" Class 125 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with ProPort Casing - 2" NPT RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

K-KK with Relief Valve - 2" NPT RH/LH PDF

STEP

K-KK with Relief Valve - 4" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 125 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 2" Class 250 ANSI RH/LH PDF

K-KK with RV and ProPort Casing - 3" Class 150 ANSI RH/LH PDF

STEP

K-KK with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with Plain Head - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2" NPT RH/LH PDF

STEP

L with ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 2" NPT RH/LH PDF

STEP

L with RV and ProPort Casing - 2.5" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 2.5" Class 250 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

L with RV and ProPort Casing - 3" Class 300 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

L with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LL with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LL with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LL with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LL with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

LL with RV and ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Plain Head - 3" Class 125 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

LS with ProPort Casing - 4" Class 300 ANSI RH/LH PDF

STEP

LS with Relief Valve - 3" Class 125 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 3" Class 125 ANSI RH/LH PDF

LS with RV and ProPort Casing - 3" Class 250 ANSI RH/LH PDF

STEP

LS with RV and ProPort Casing - 4" Class 150 ANSI RH/LH PDF

STEP

Q with Plain Head - 4" Class 125 ANSI RH/LH PDF

Q with ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q with Relief Valve - 4" Class 125 ANSI RH/LH PDF

STEP

Q with RV and ProPort Casing - 4" Class 125 ANSI RH/LH PDF

Q with RV and ProPort Casing - 4" Class 250 ANSI RH/LH PDF

Q-QS with RV and ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with Plain Head - 6" Class 125 ANSI Opposite PDF

STEP

QS with ProPort Casing - 6" Class 125 ANSI Opposite PDF

QS with ProPort Casing - 6" Class 250 ANSI Opposite PDF

QS with Relief Valve - 6" Class 125 ANSI Opposite PDF

STEP

QS with RV and ProPort Casing - 6" Class 250 ANSI Opposite PDF