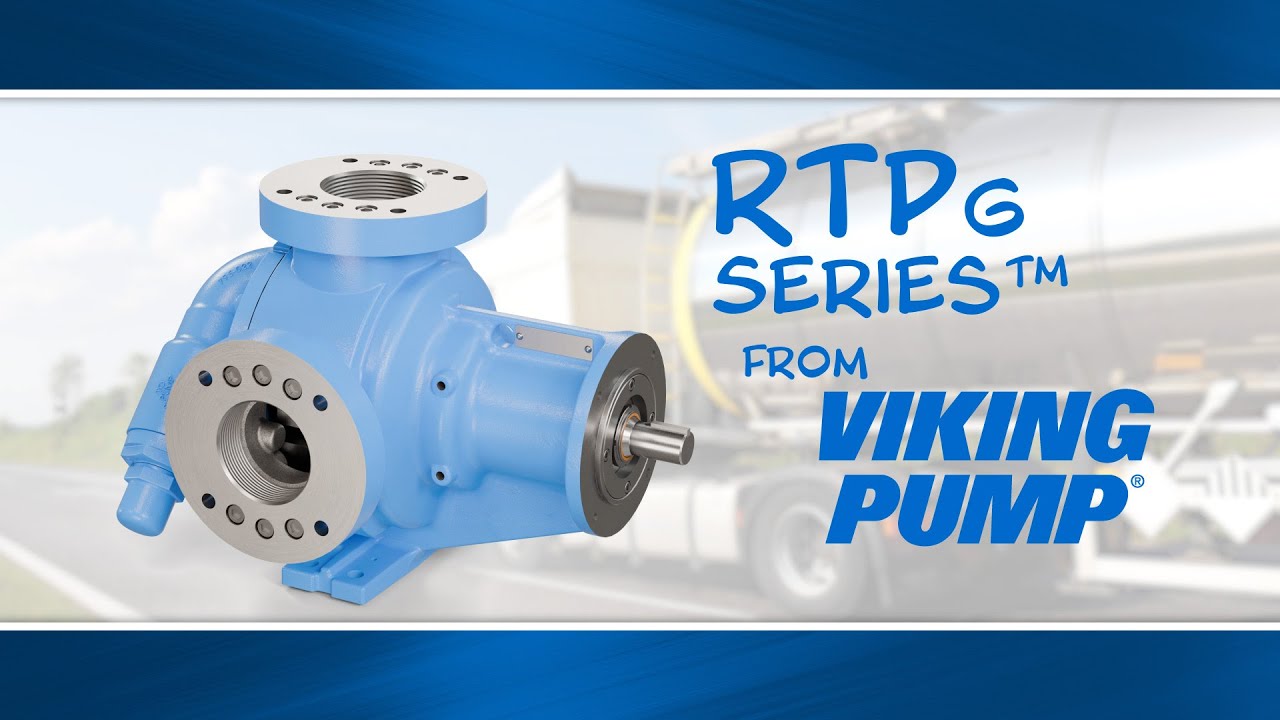

Une série de pompes à palettes Viking, ainsi nommées en raison de leur capacité à traiter des liquides à faible viscosité, même à des pressions élevées

Pompe à faible viscosité

What is a Low Viscosity Pump?

A Low Viscosity Pump is a series of Viking Pump vane pump named for their ability to handle low viscosity liquids at high pressures.

How does a Low Viscosity Pump work?

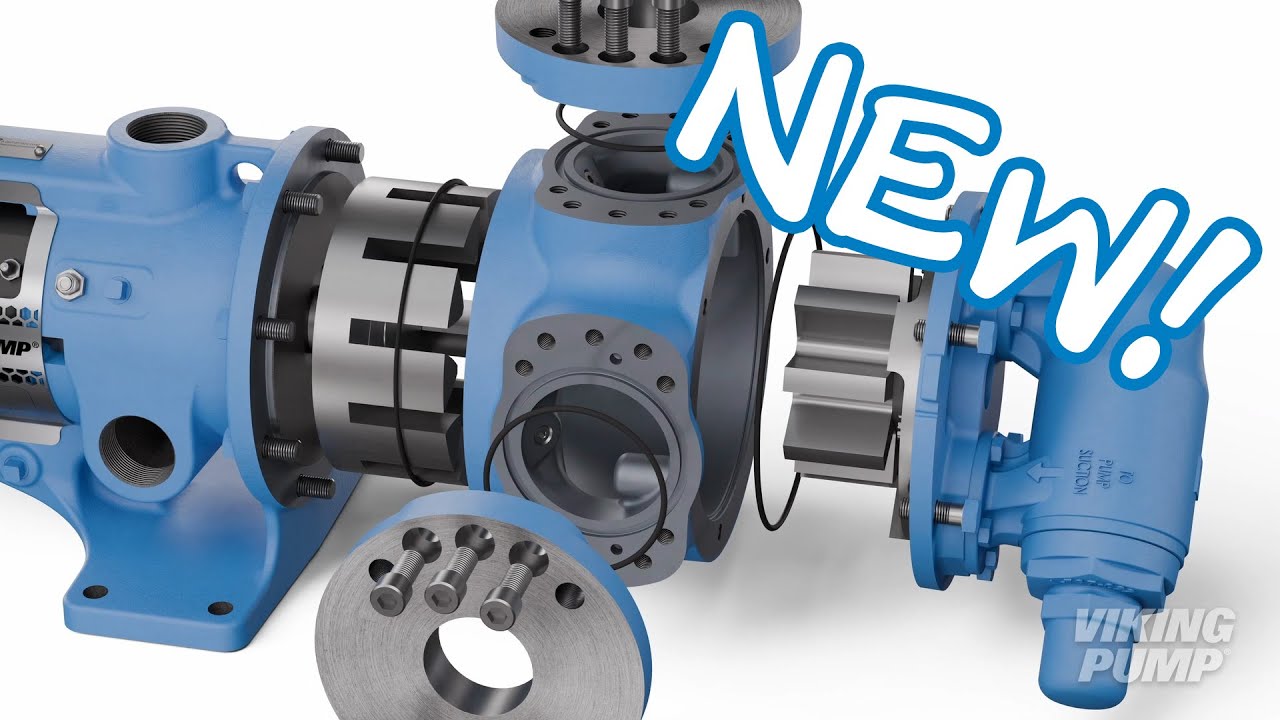

Low Viscosity Pumps, or vane pumps move fluid using the rotary motion of multiple sliding vanes. Vane pumps consist of a slotted rotor rotating inside a cam shaped housing. This rotor is located close to the wall of the cam so that a crescent-shaped cavity is formed on the opposite wall.

Each rotor slot contains a sliding vane. As the rotor rotates, centrifugal force, hydraulic pressure, and push rods work together to extend each vane to the casing wall. This creates an expanding cavity on the inlet side – creating a vacuum which pulls liquid into the pump. Liquid is trapped between the vanes and the casing wall. The rotor rotation moves the liquid cavities around to the outlet side of the pump.

At the outlet side, the vanes are forced back into their slots, decreasing the cavity size and forcing the liquid through the outlet port.

What are Low Viscosity Pumps used for?

Since Low Viscosity Pumps have vanes that run in contact with the casing wall, they are commonly used in thin liquid applications like solvents, alcohols, and various acids or bases.