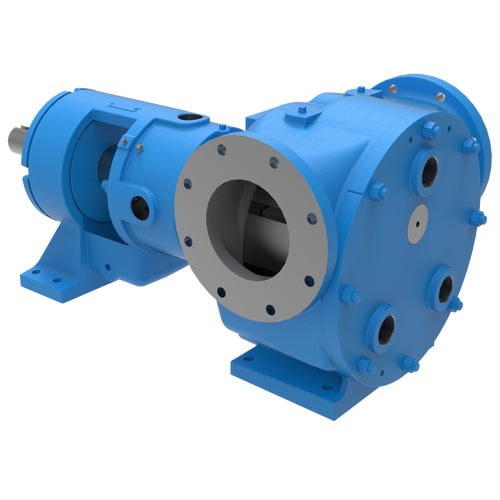

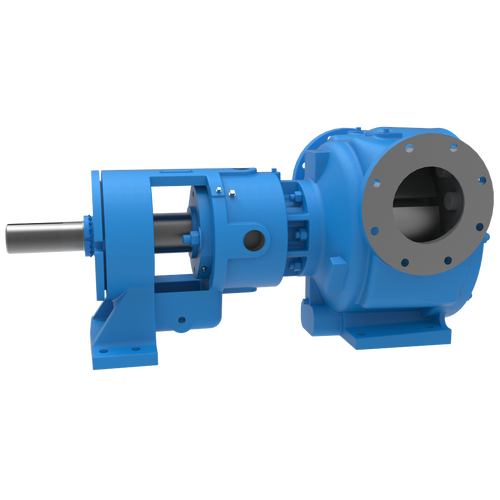

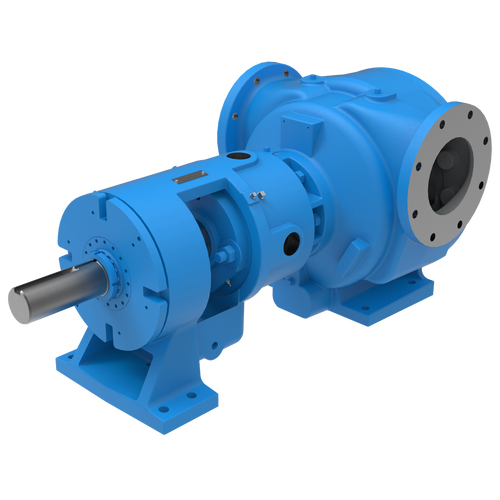

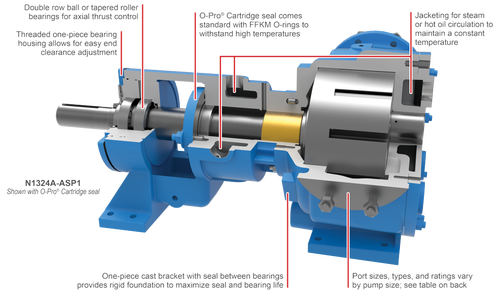

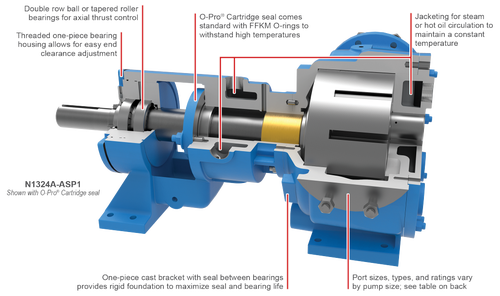

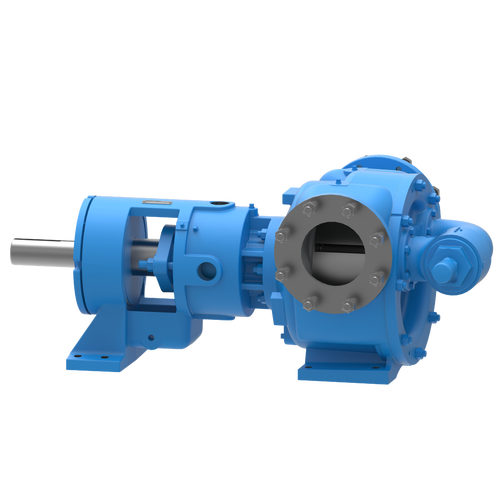

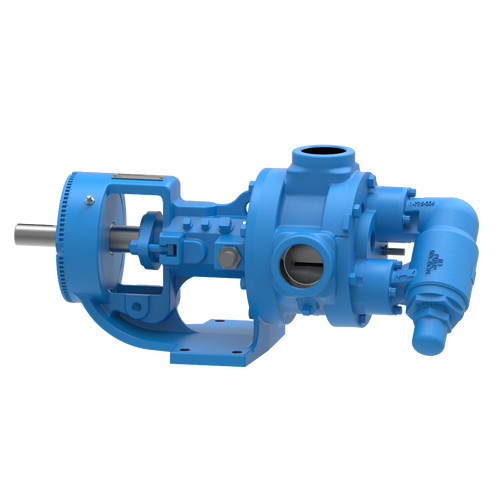

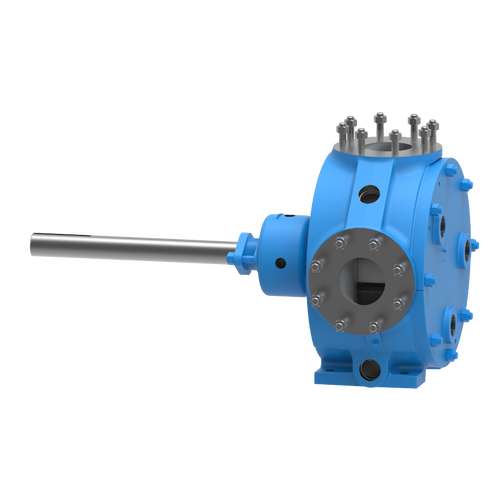

The 1324A-ASP Series™ internal gear pump is designed specifically for handling asphalt, bitumen, pitch, bunker oils, residual oils and related materials that solidify at ambient temperatures. It can handle flows from 110 to 885 GPM (25to 201 m³/h).

Features & Benefits

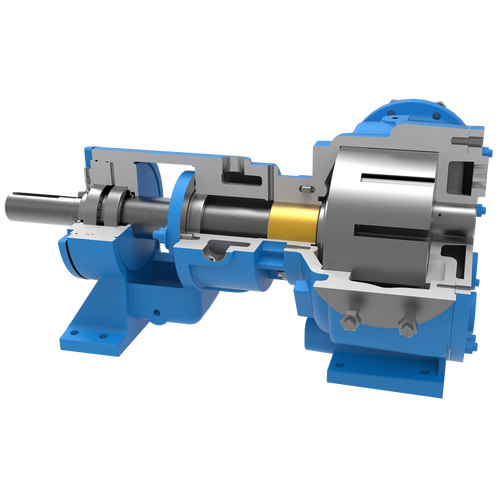

- Rugged design provides superior performance in asphalt applications

- Tight clearances offer high efficiency and excellent priming capabilities

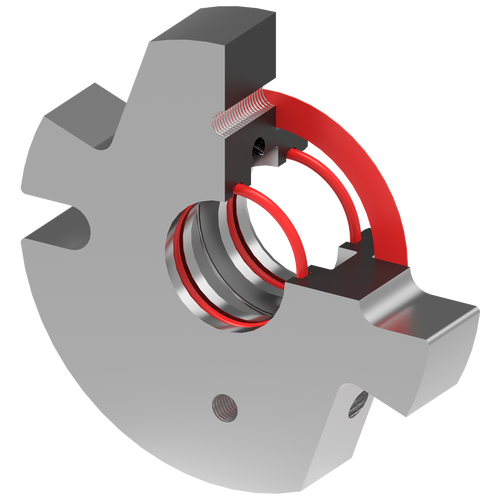

- O-Pro® Cartridge seal combines reliable sealing with easy maintenance