Sugar Solution

A generic term used to describe a mixture of water with a sweetener such as sucrose derived from sugar cane or sugar beets.

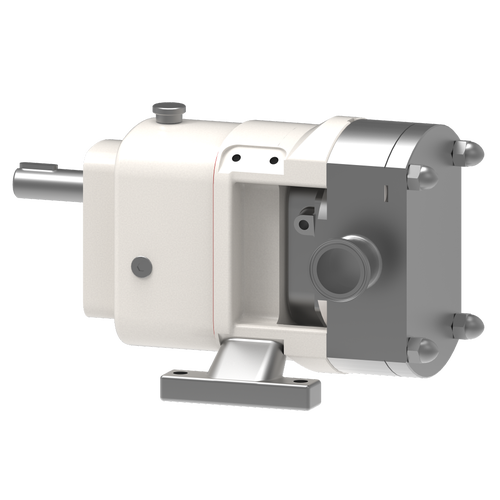

- 316L stainless steel

- Mechanical seals

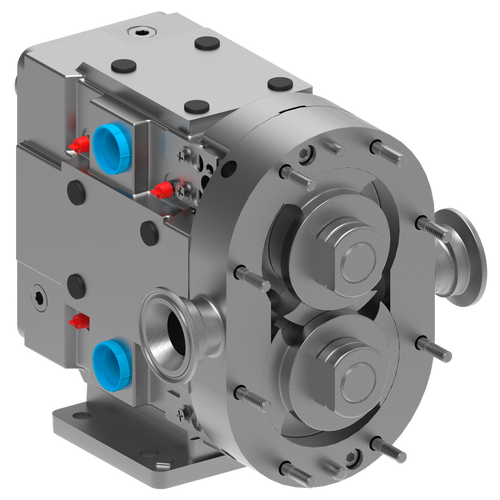

- 316L stainless steel

- O Ring or mechanical seals

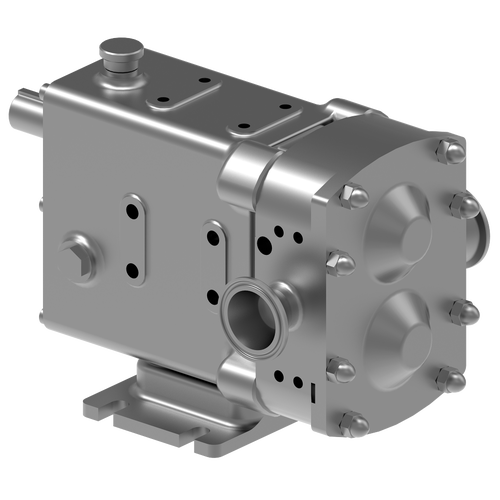

- 316L stainless steel

- O Ring or mechanical seals

Business Line